Parallel-Plate Capacitor and Waveguide

This tutorial covers

Model: Learn how to set up the components of a basic 3D FDTD model, including:

Create conductors in the simulation box.

Create a Cartesian mesh (Yee cells) and correctly apply the 1/3-2/3 rule to ensure accuracy.

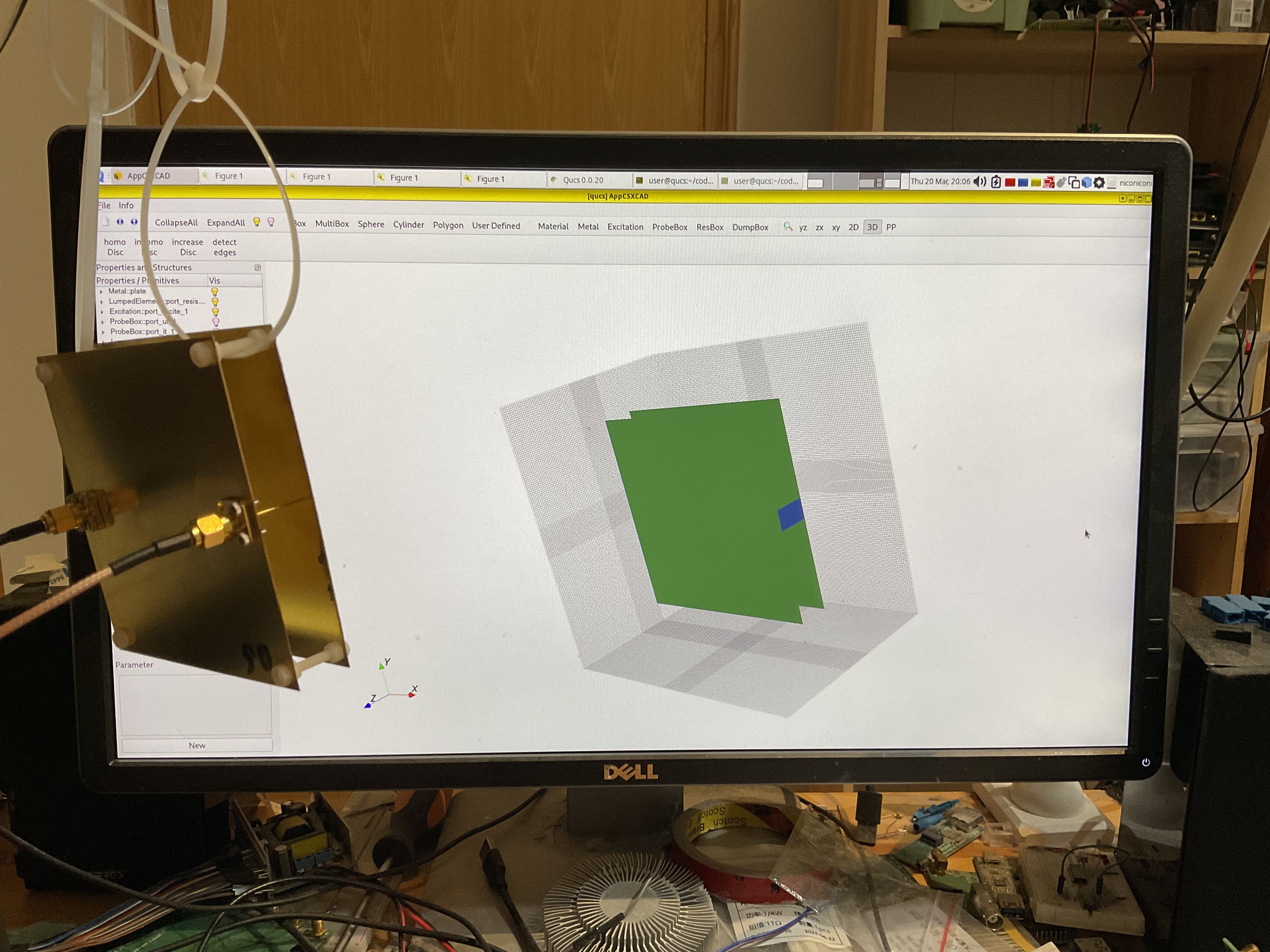

Inspect the finished 3D model with AppCSXCAD.

Boundary Conditions: Understand the available boundary conditions in openEMS and their physical interpretation.

Ports and Excitations. Add an excitation port with signal. Understand the purpose of ports and the existence of different port types. Recognize a Gaussian pulse’s waveform, frequency spectrum, and its advantages in FDTD simulations.

Simulate: Run simulation to obtain the S-parameters (frequency response) of the waveguide. Understand the meanings of convergence, divergence, and “blow-ups”.

Built-in Post-Processing: Calculate the final frequency response (S-parameters) and time-domain signal waveforms.

Plot S-parameters, Z-parameters, time-domain waveforms via matplotlib.

Save the raw electromagnetic field dump.

Third-Party Post-Processing: Know the common tools for data analysis.

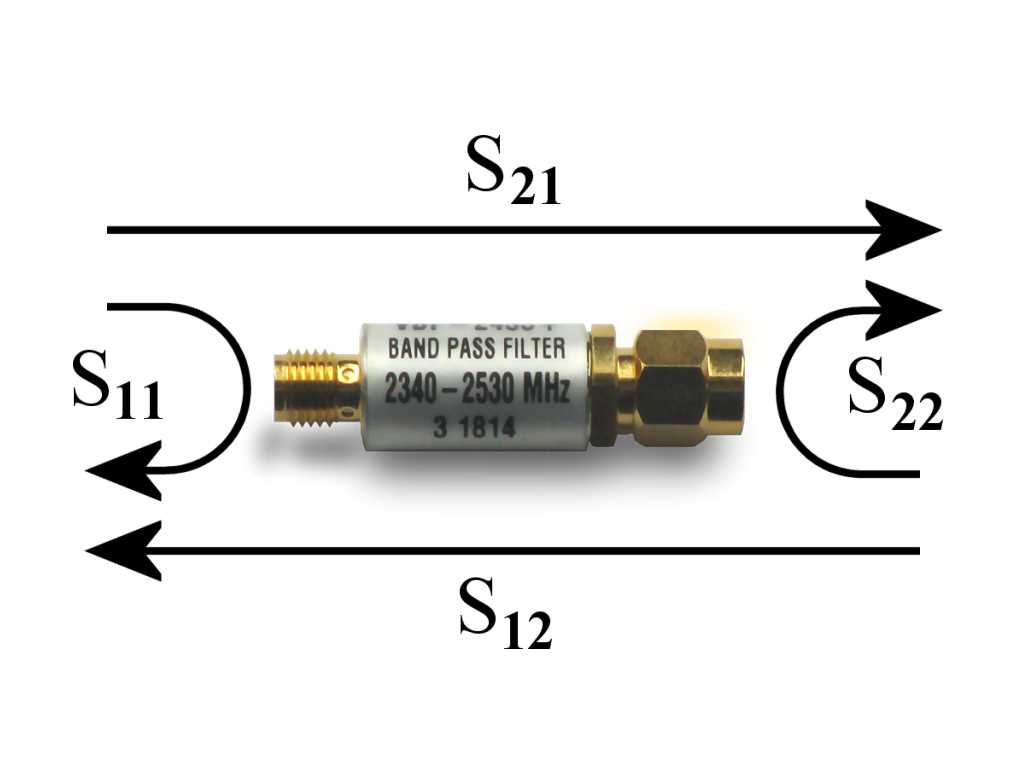

Understand that S-parameters are the parameters that characterize a linear circuit’s frequency response as a black box without knowledge of the underlying physics. The physics is open to interpretation.

Plot S-parameters on Smith, line charts, and calculate Time-Domain Reflectometry via

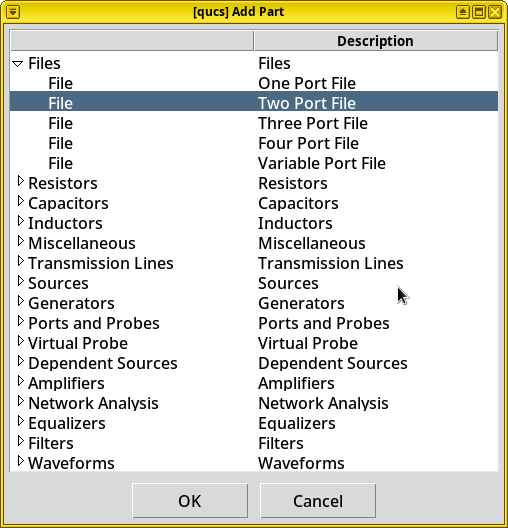

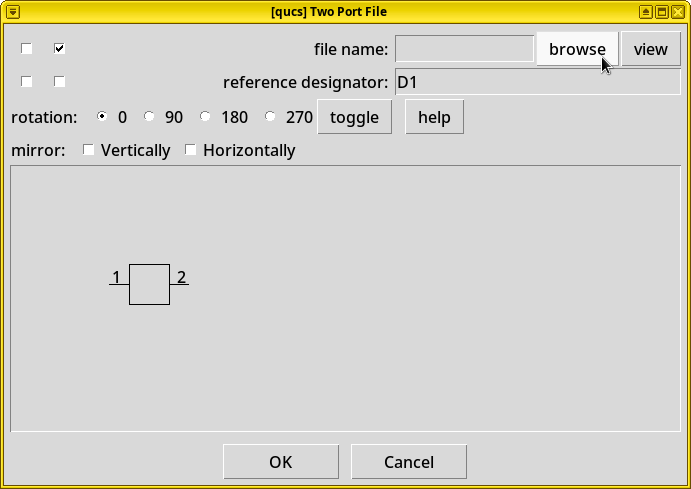

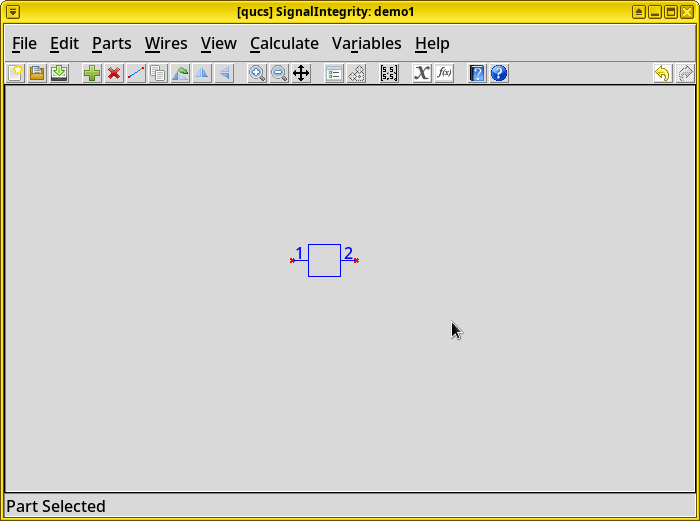

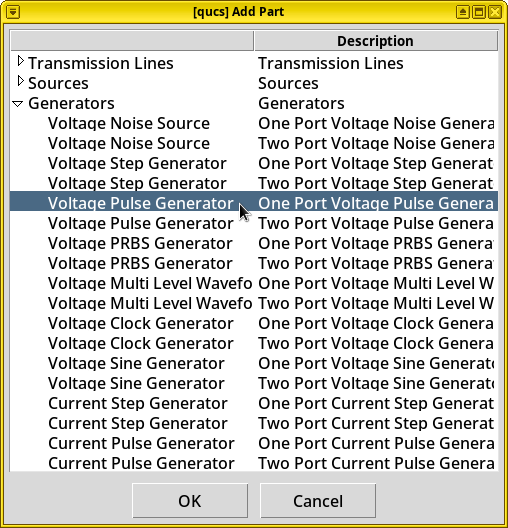

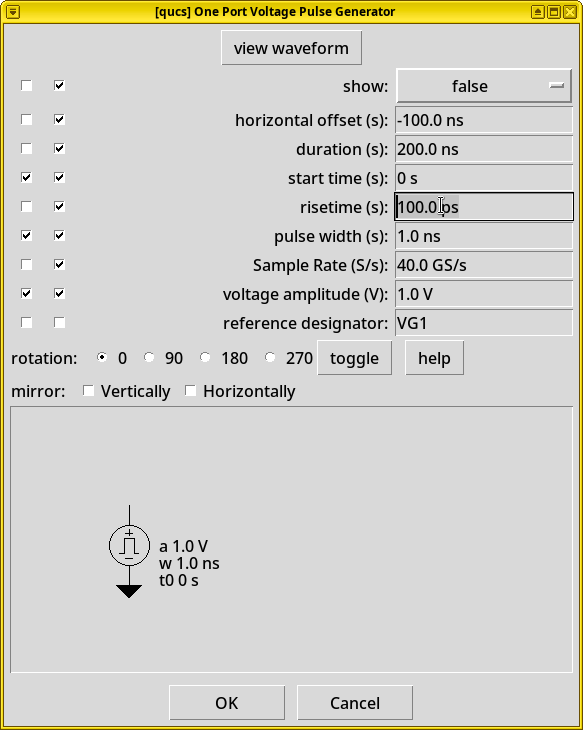

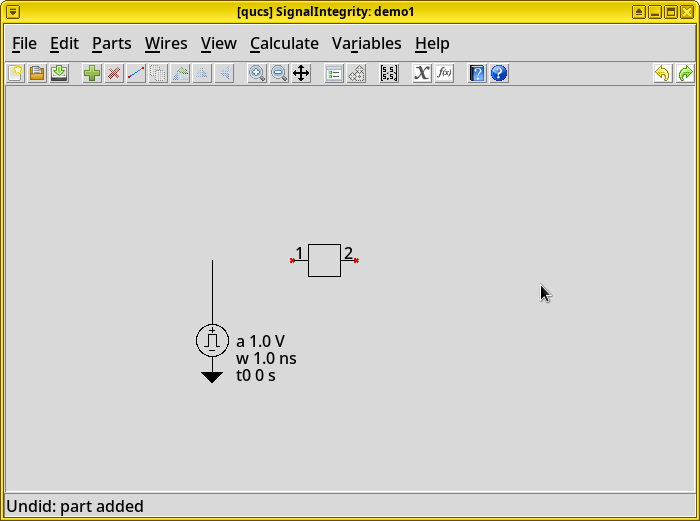

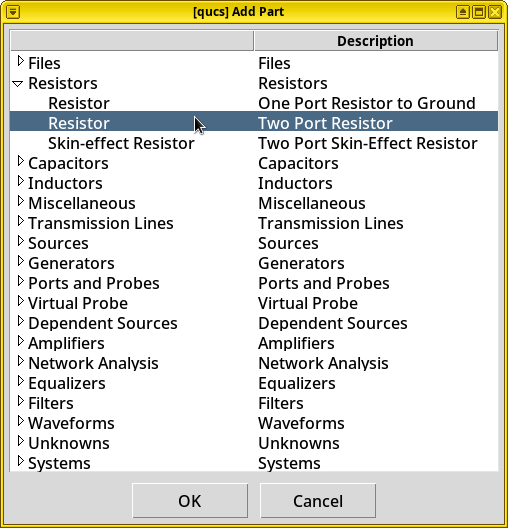

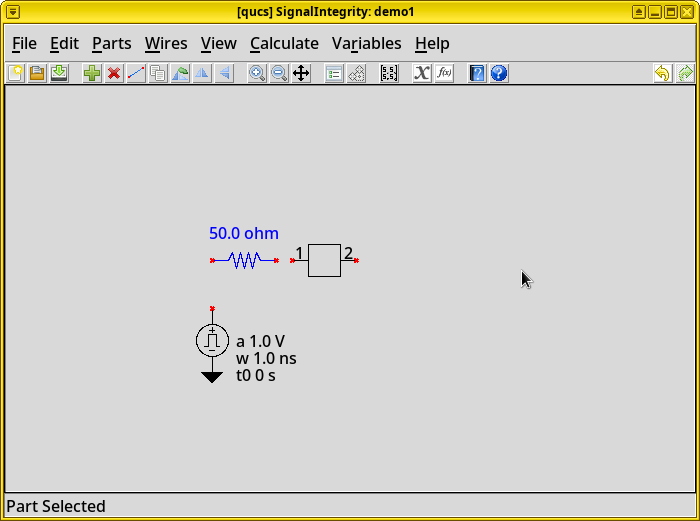

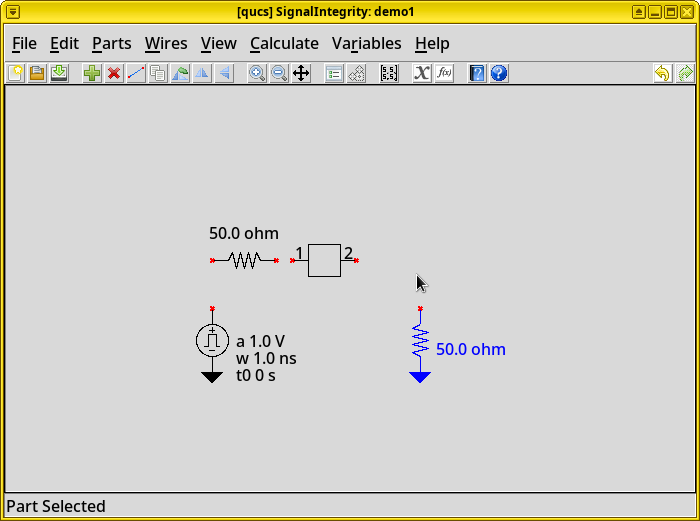

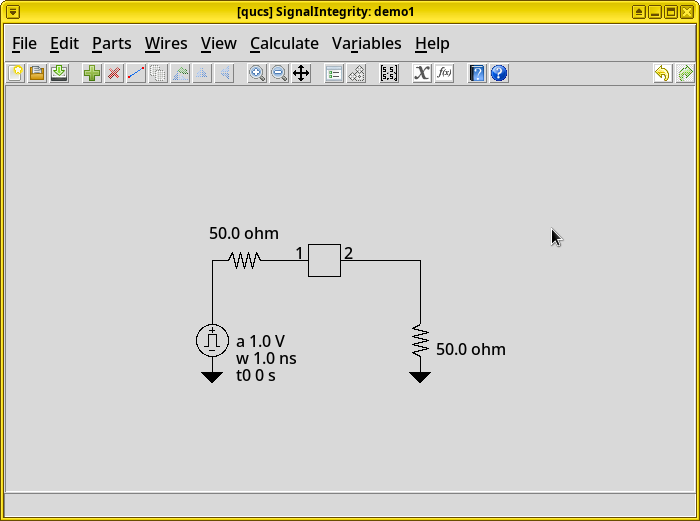

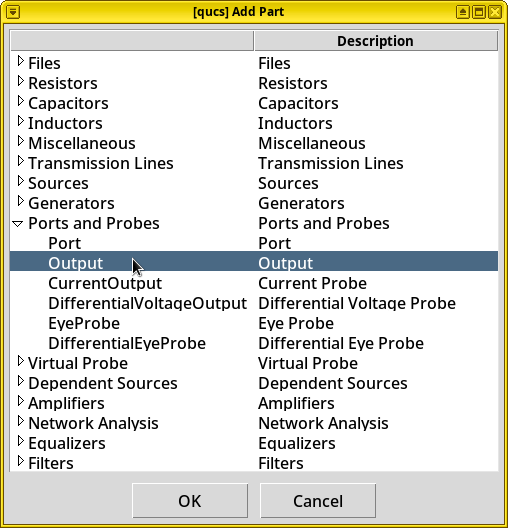

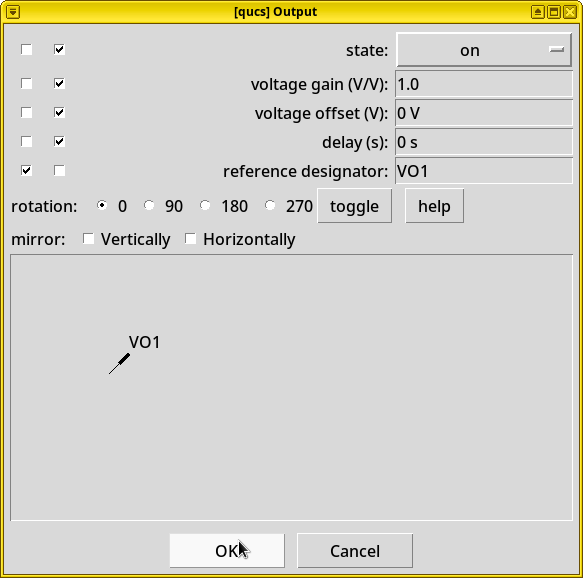

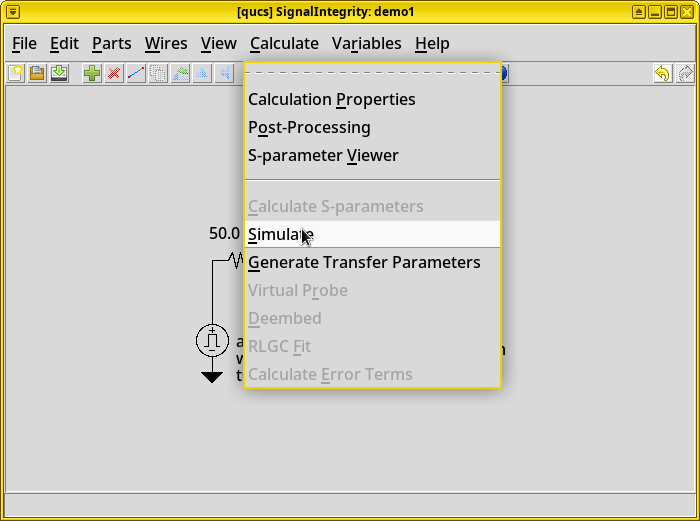

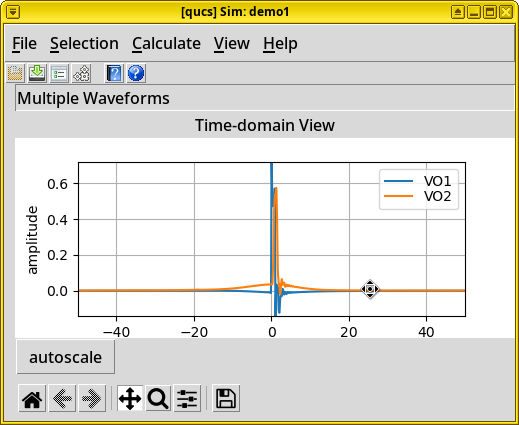

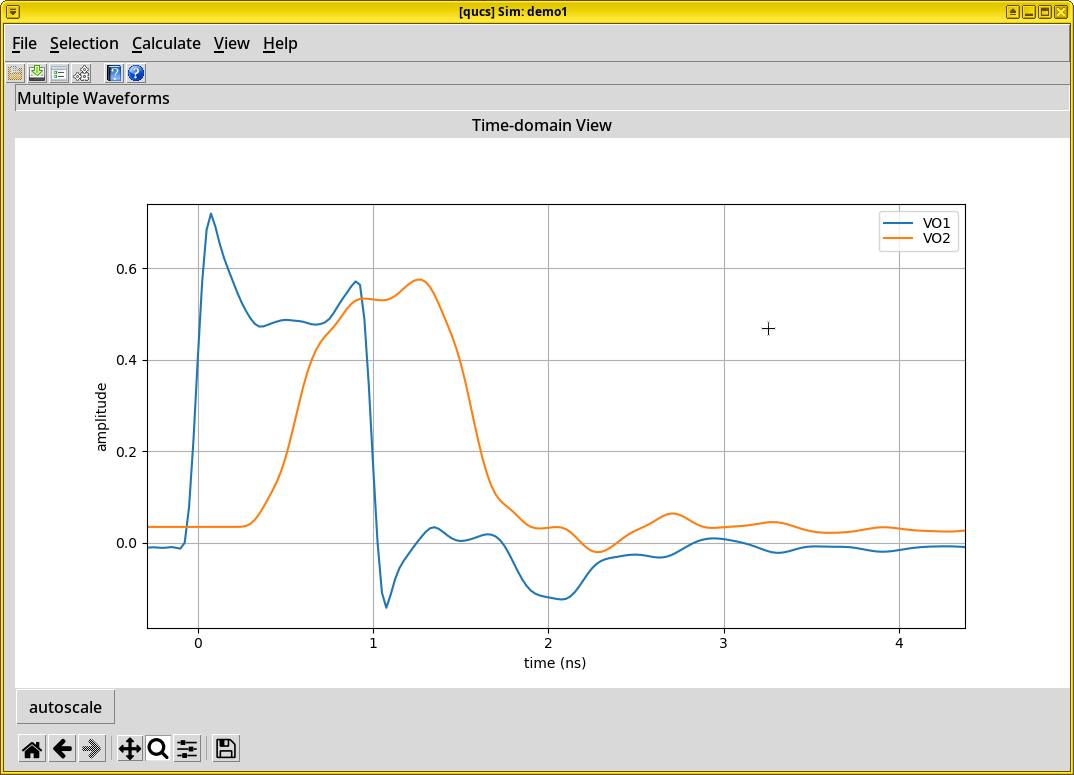

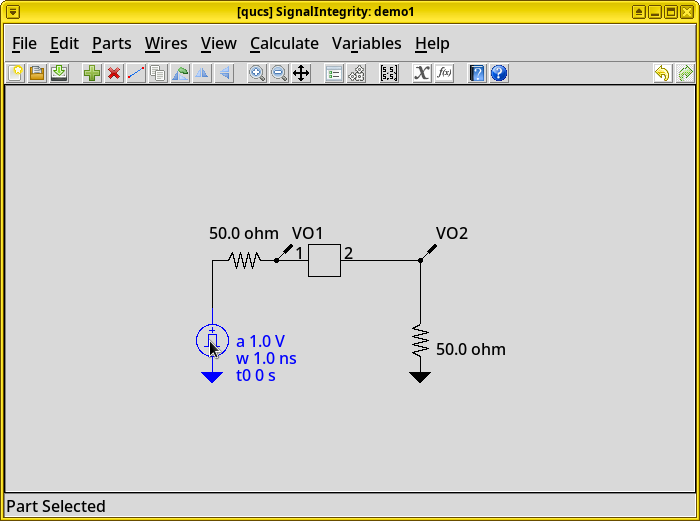

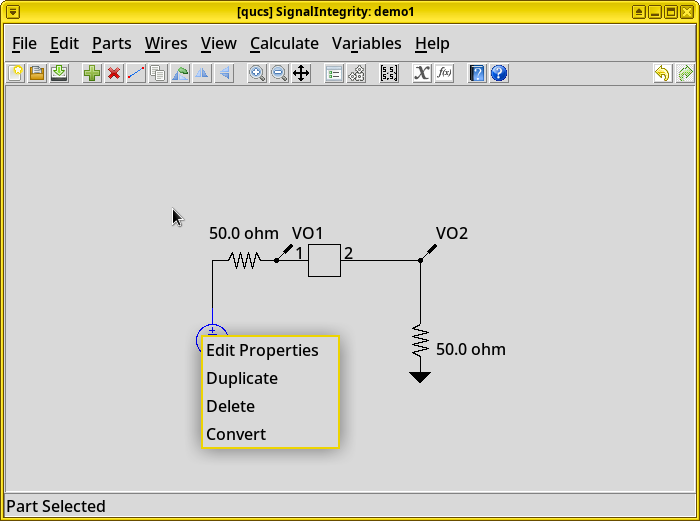

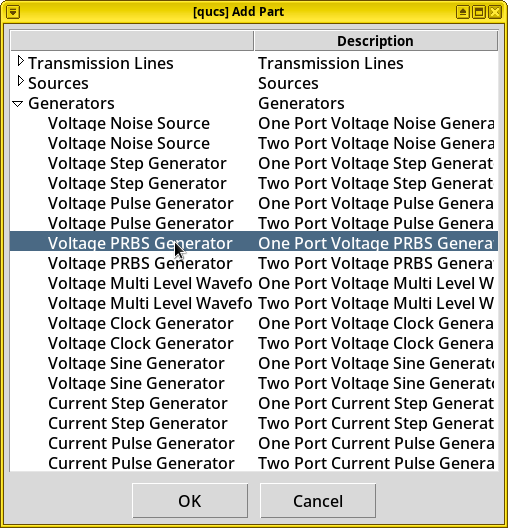

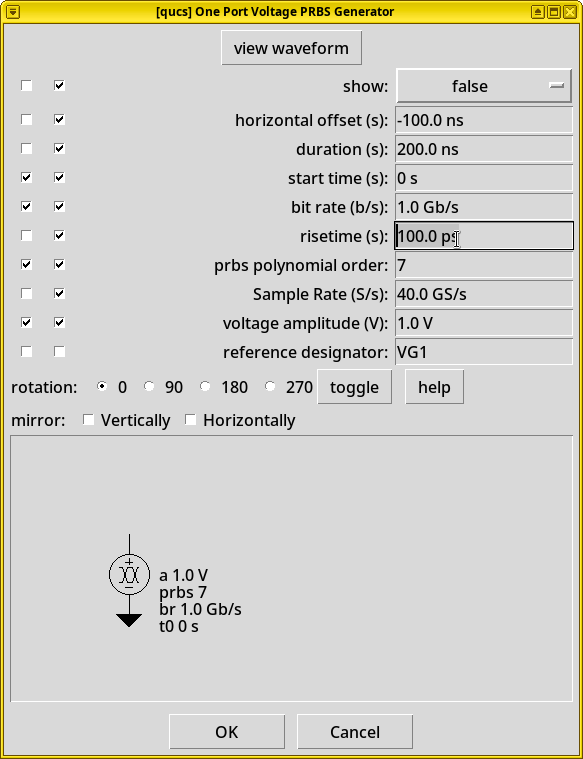

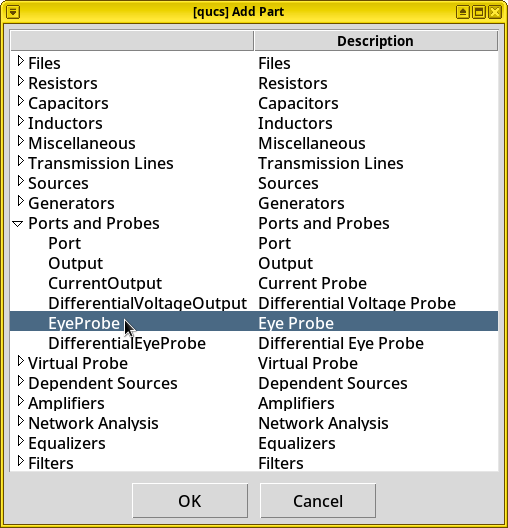

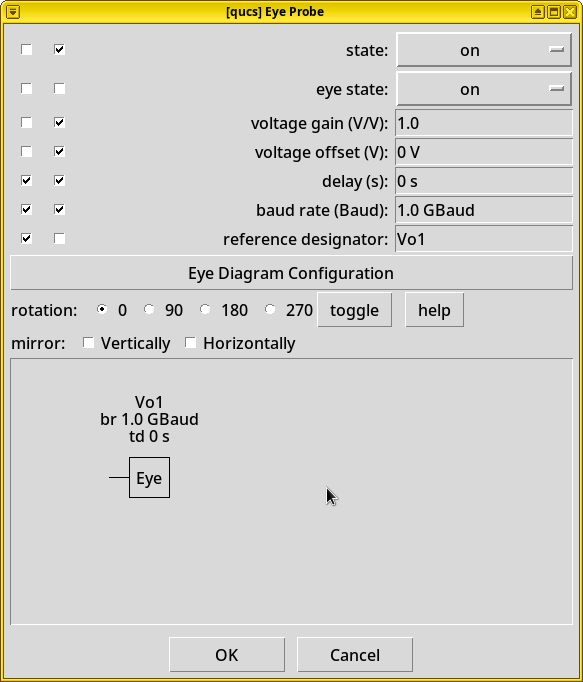

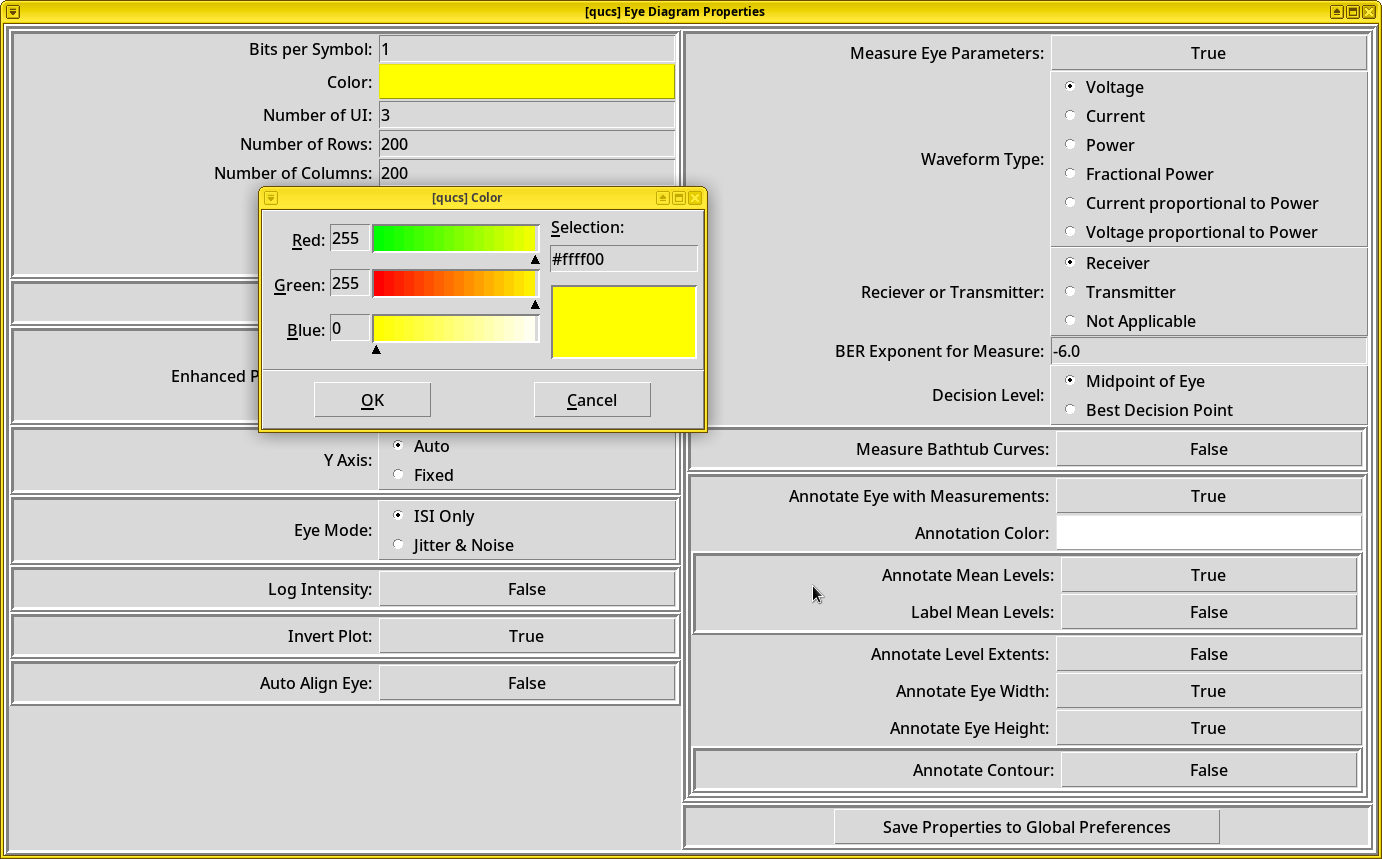

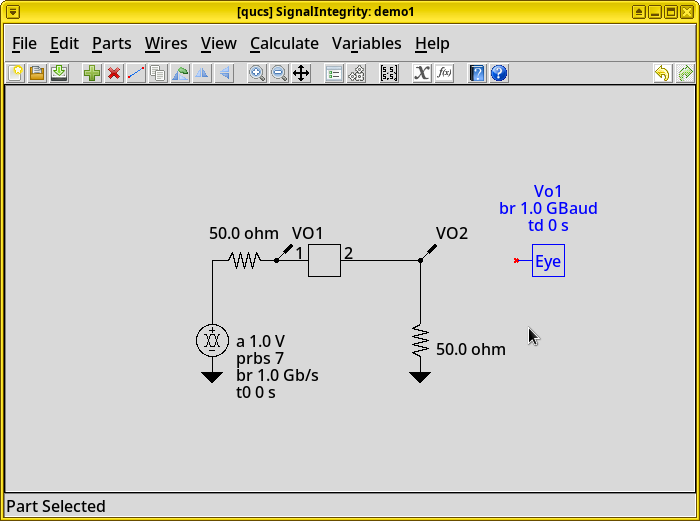

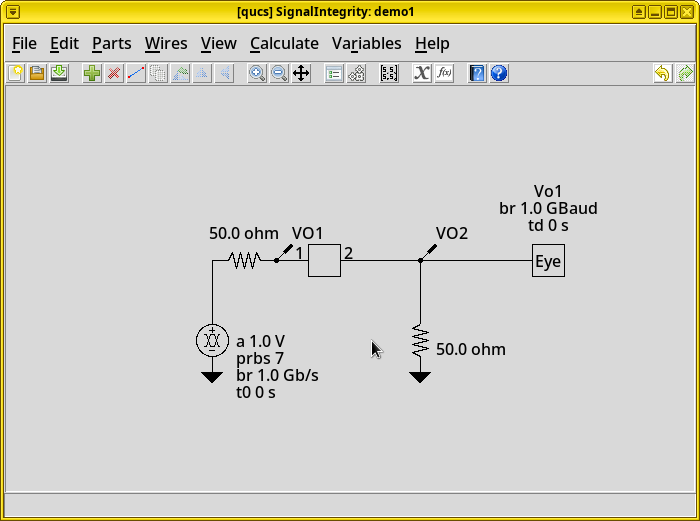

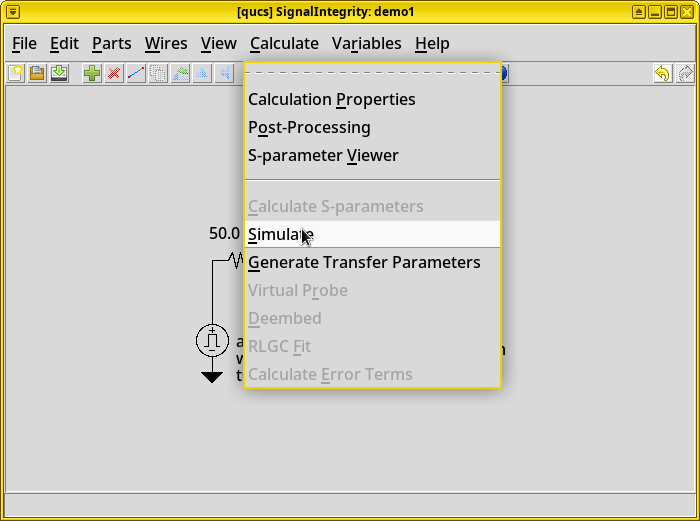

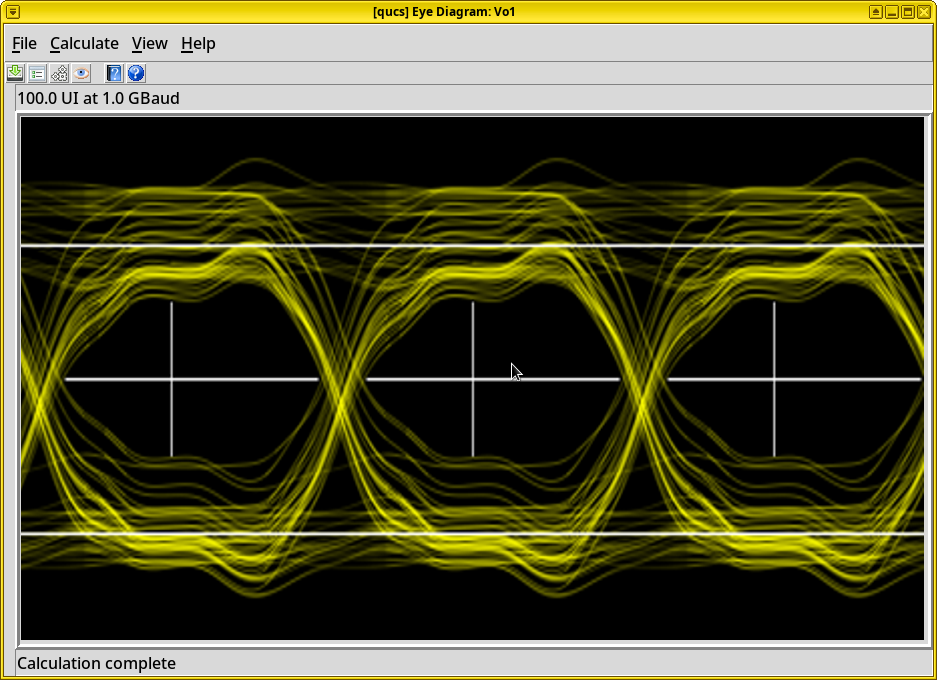

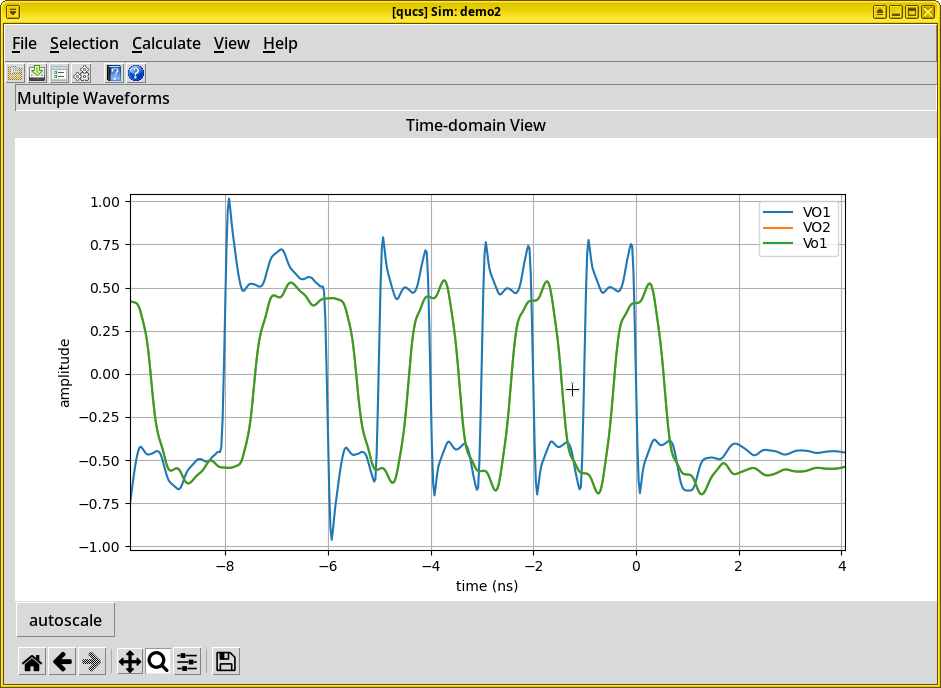

scikit-rf.Simulate the waveguide’s time-domain response and eye diagrams via the Python package SignalIntegrity

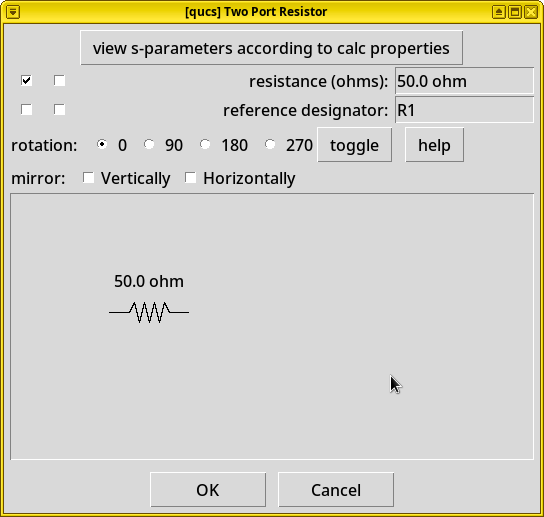

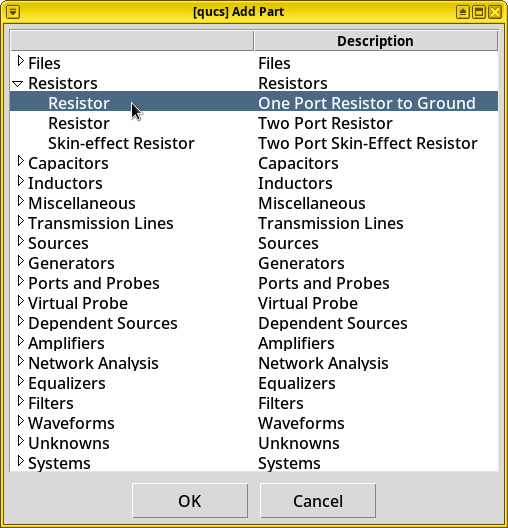

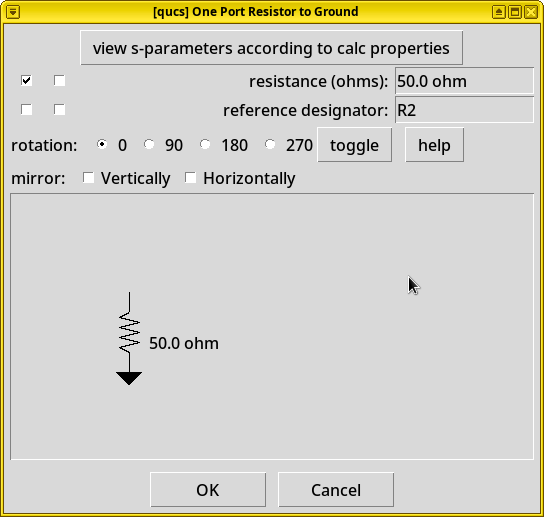

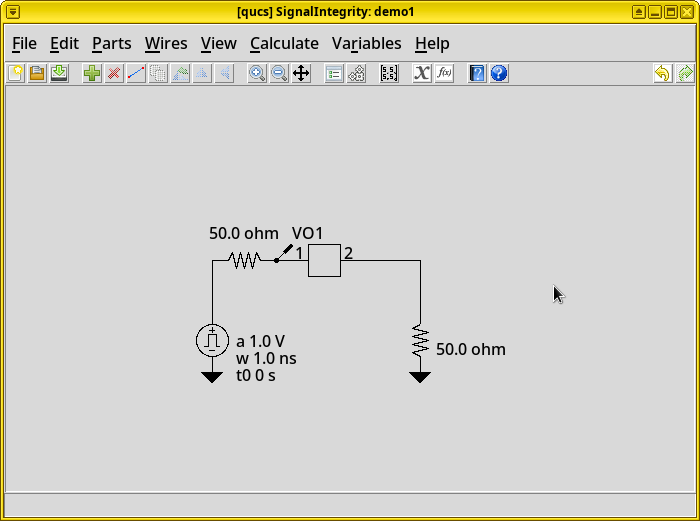

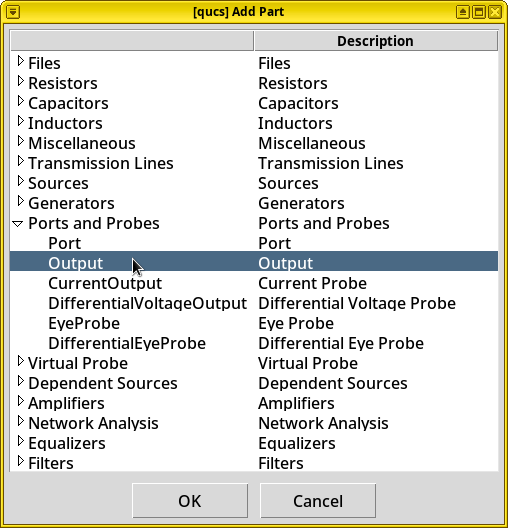

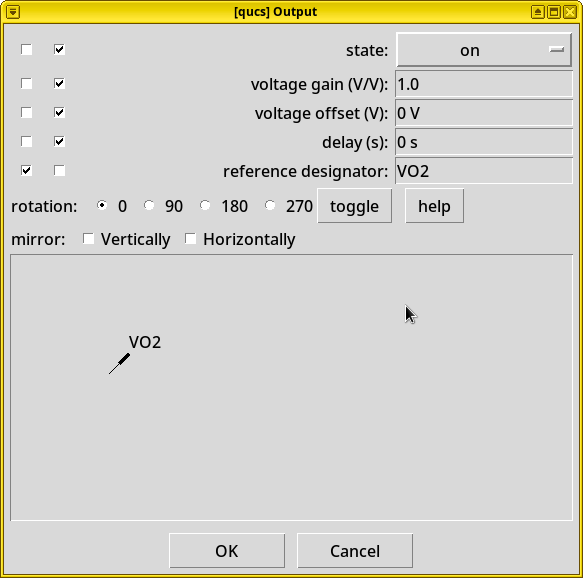

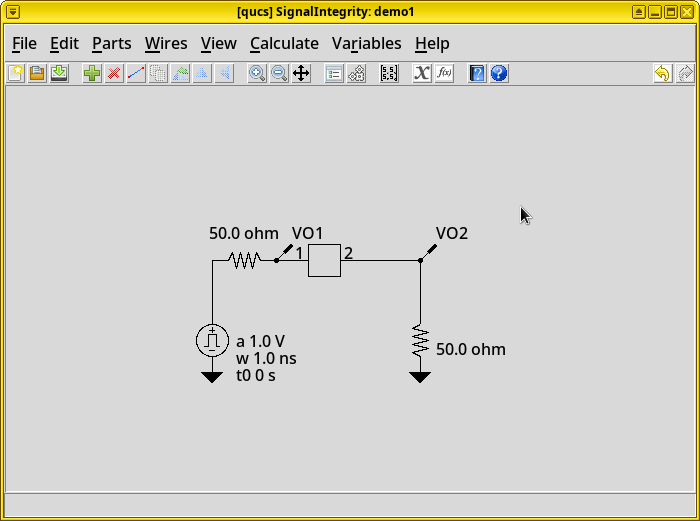

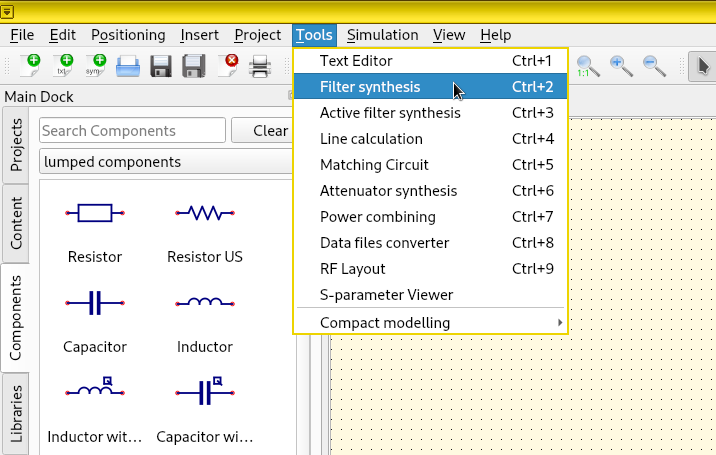

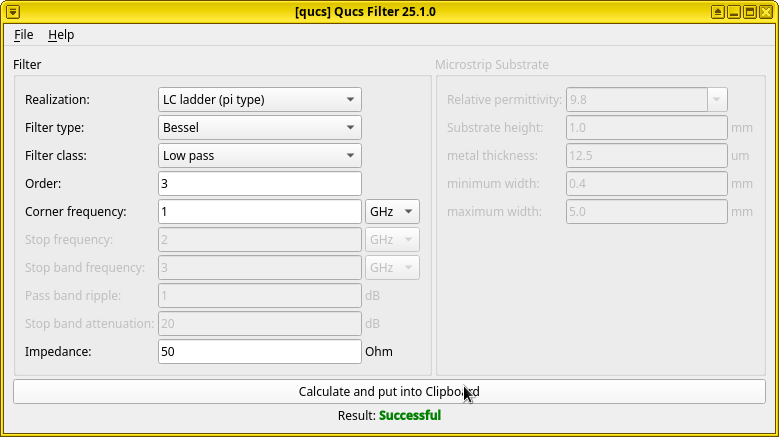

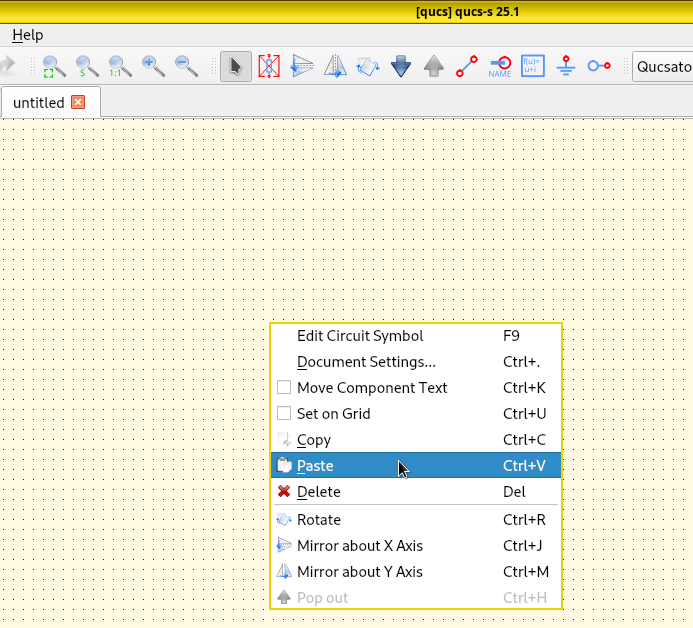

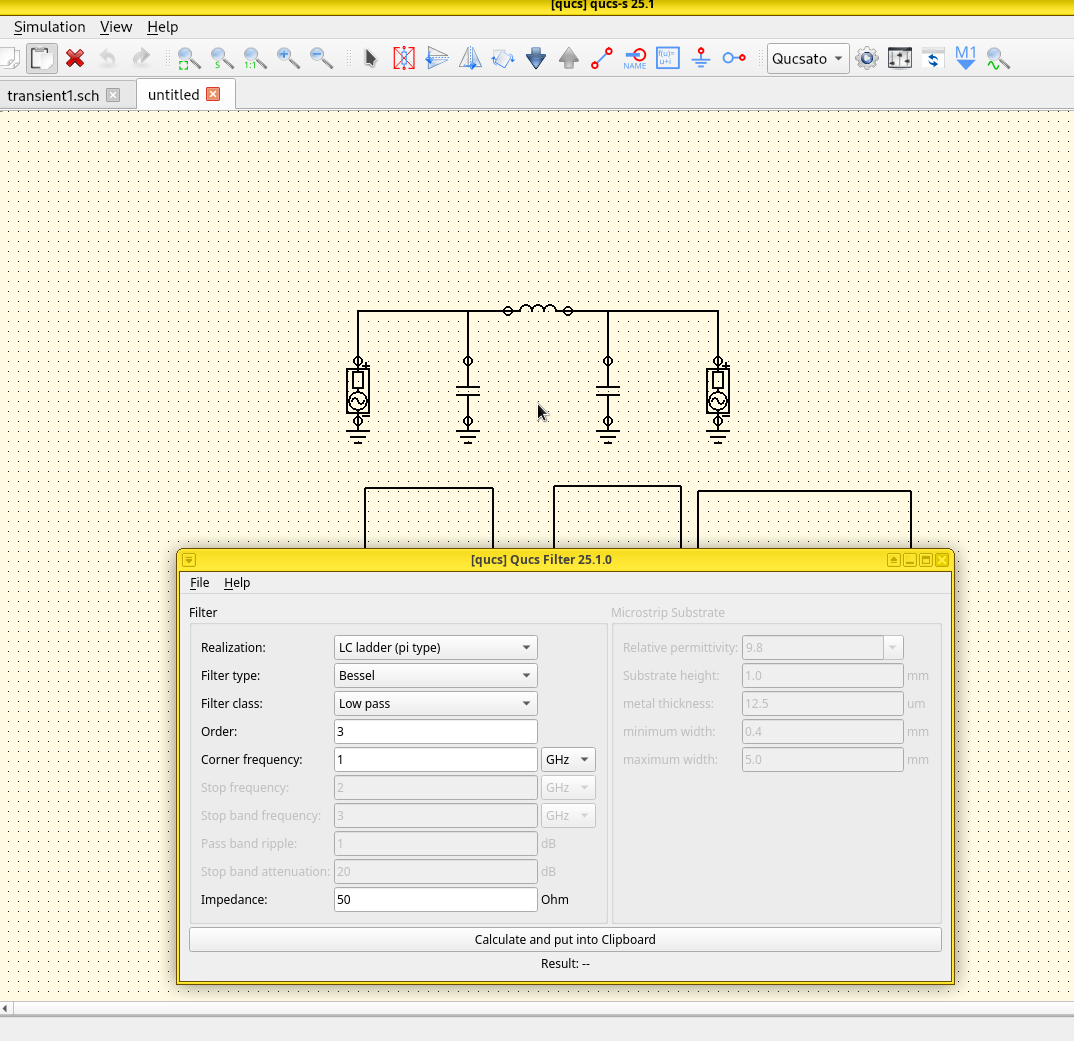

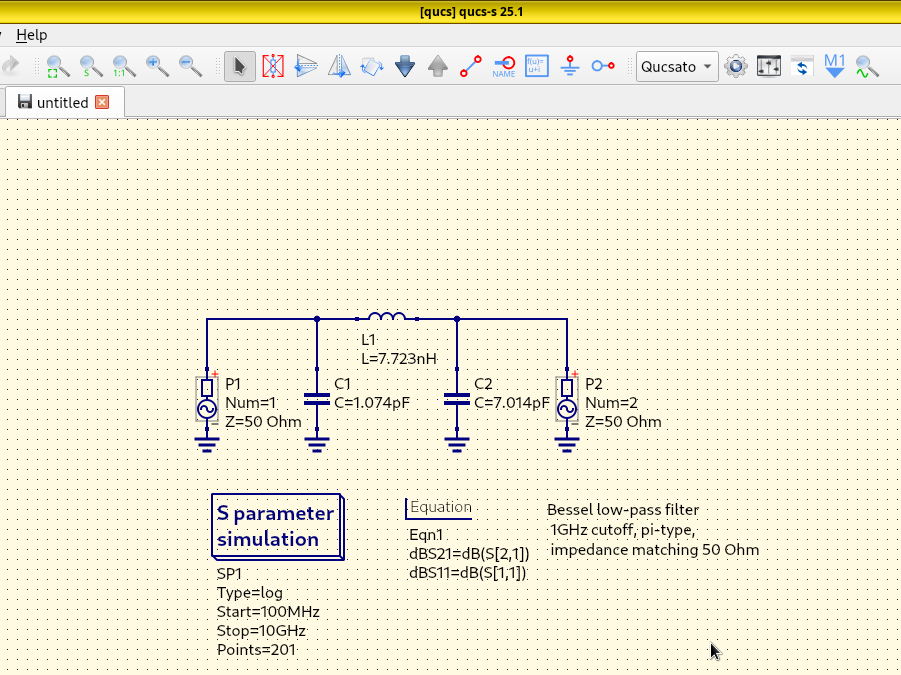

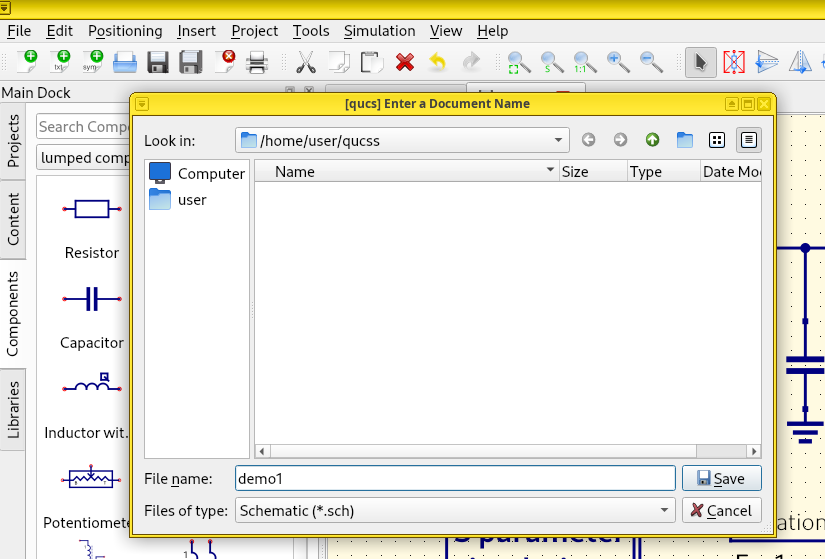

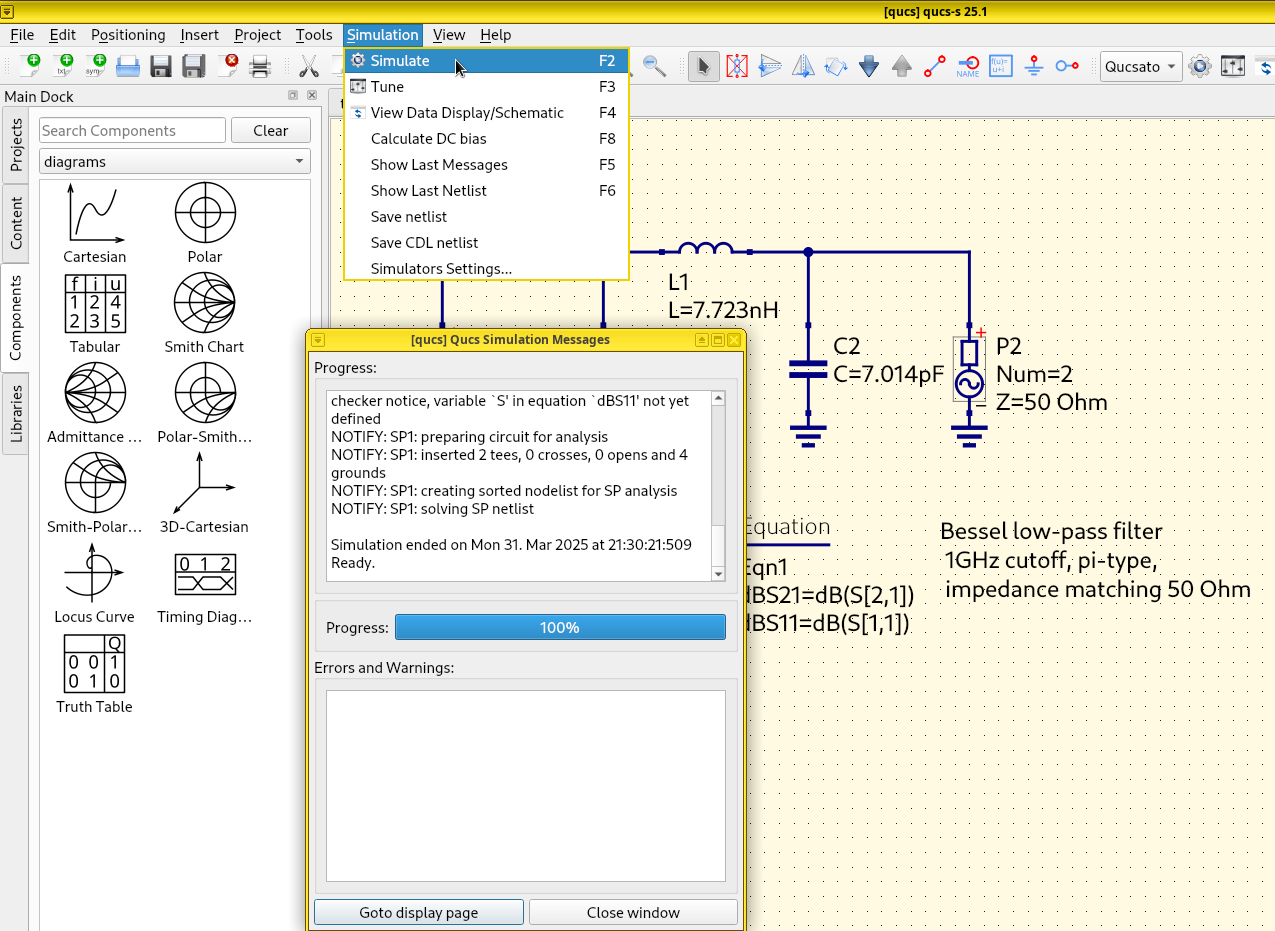

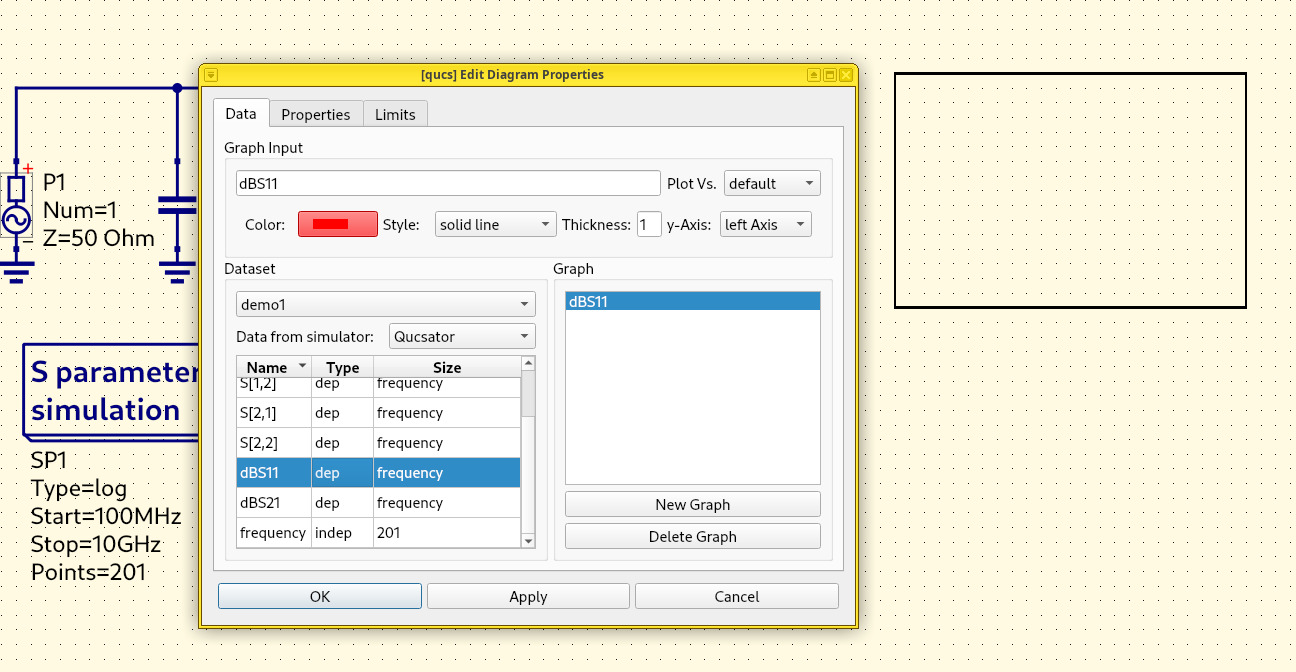

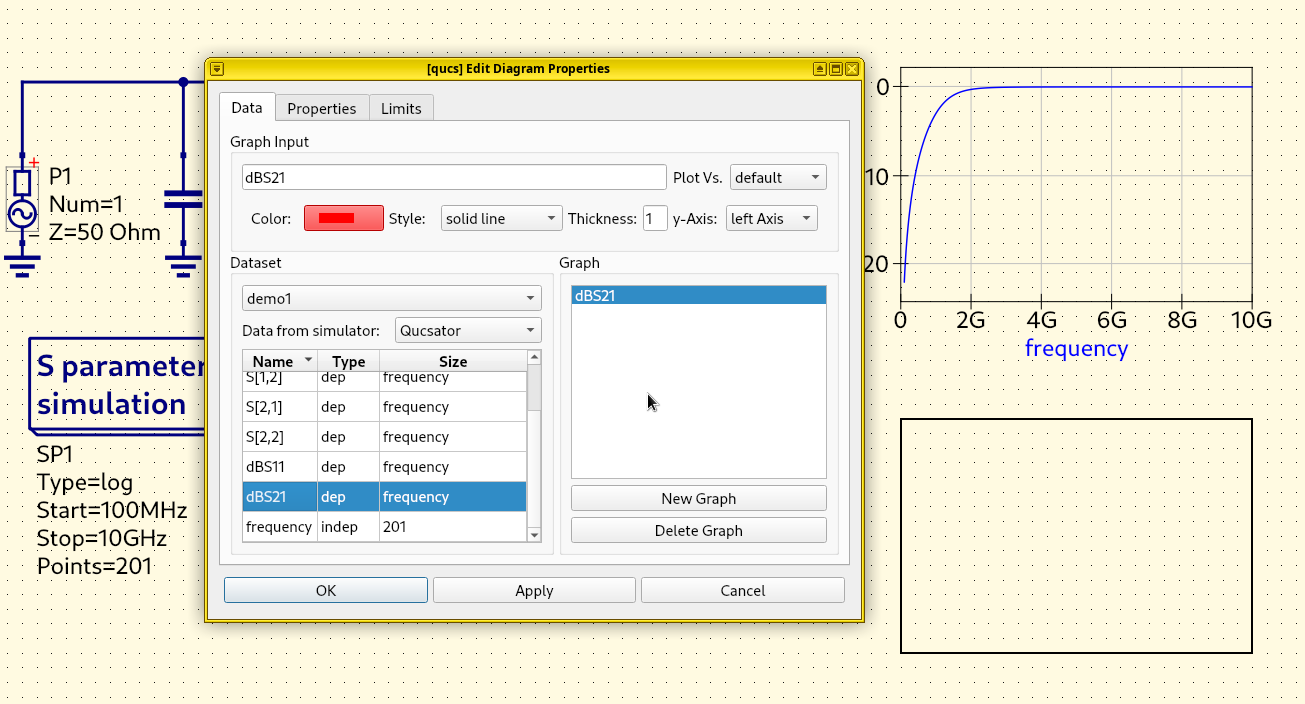

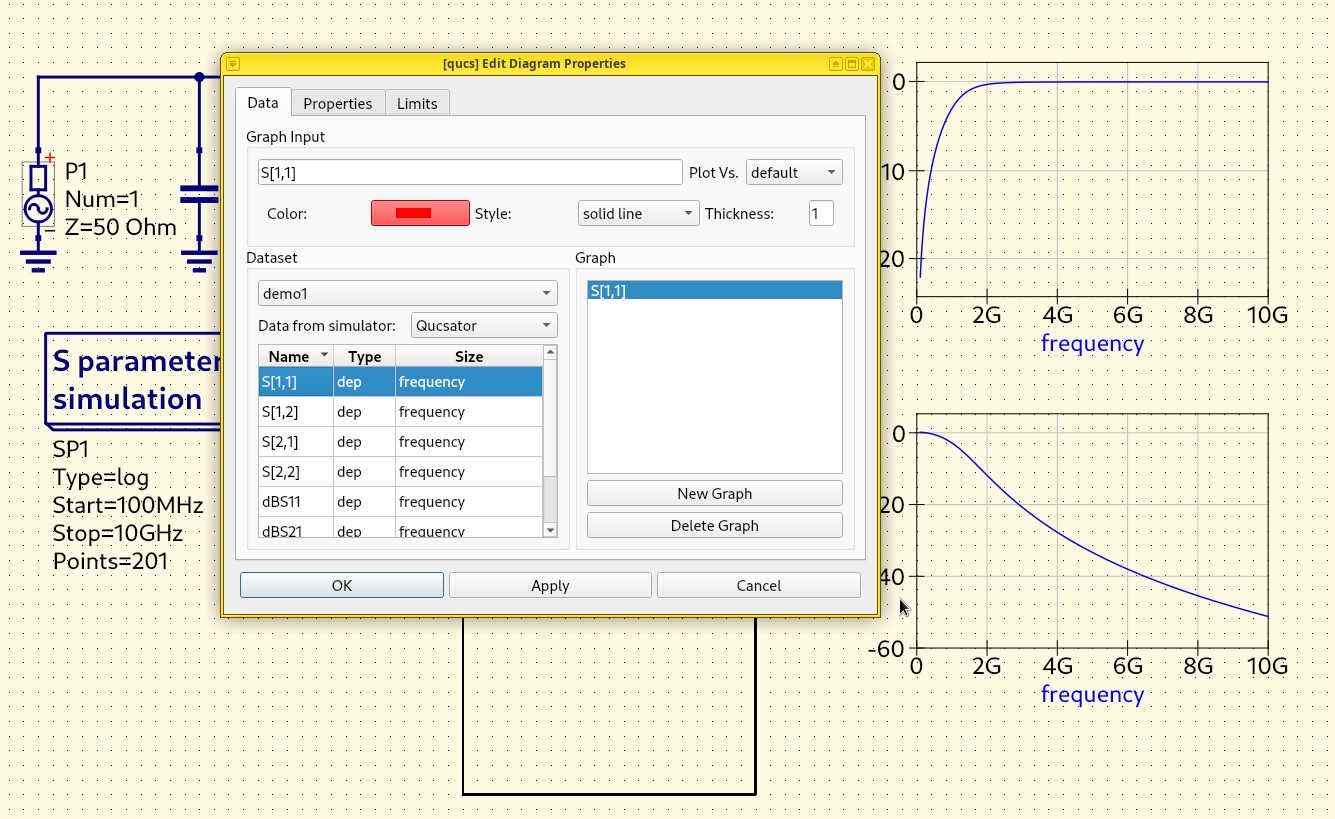

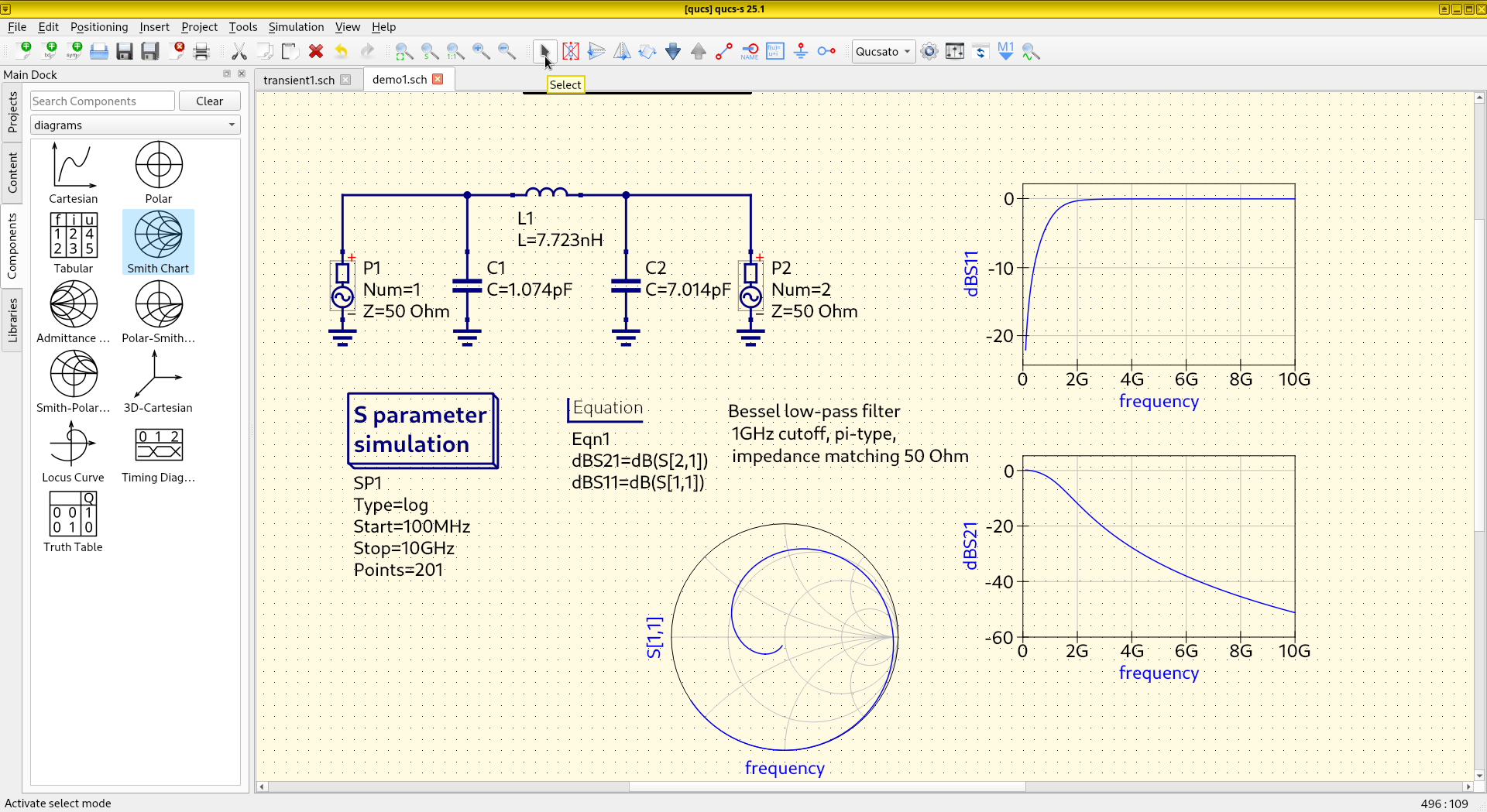

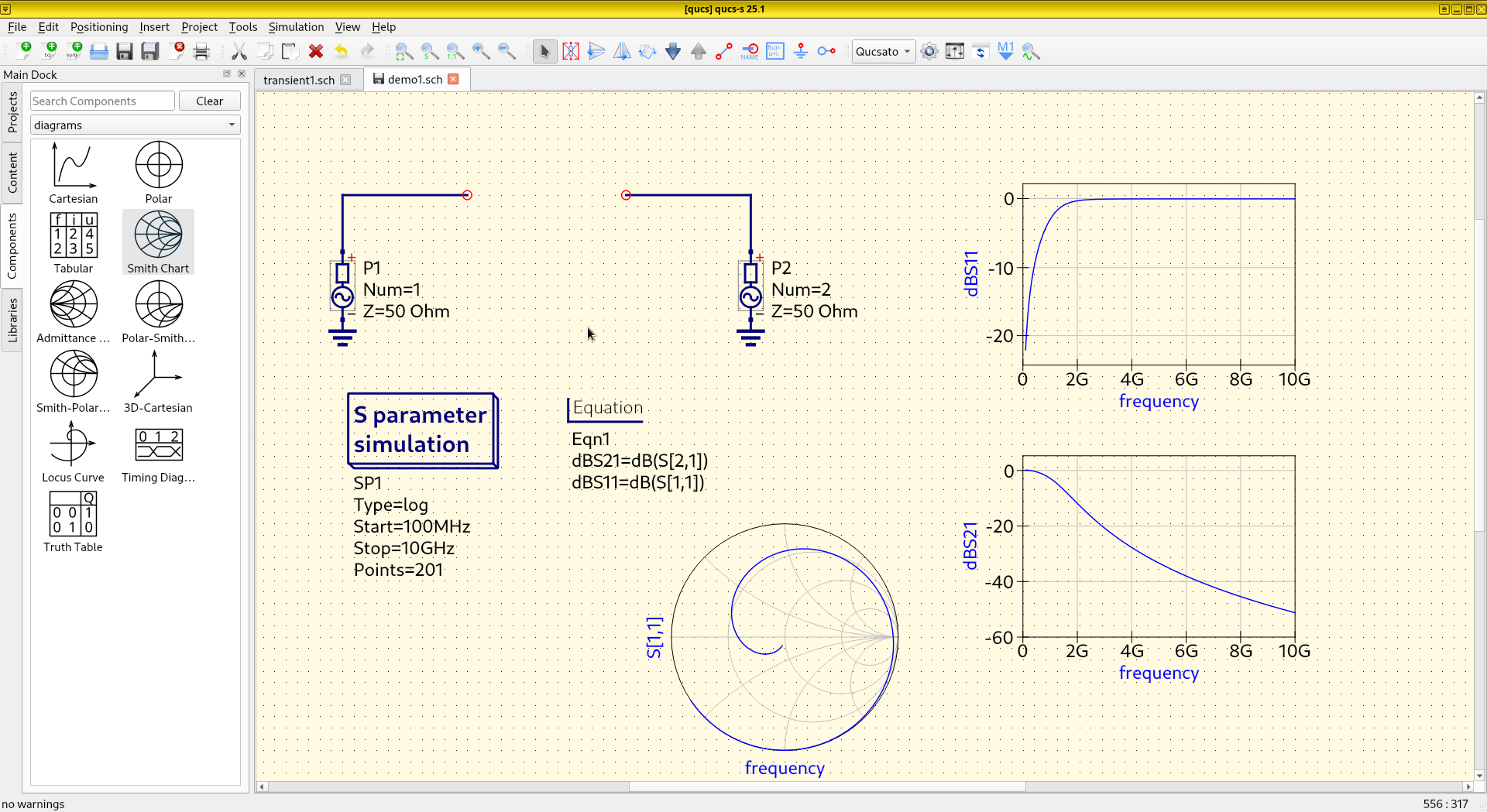

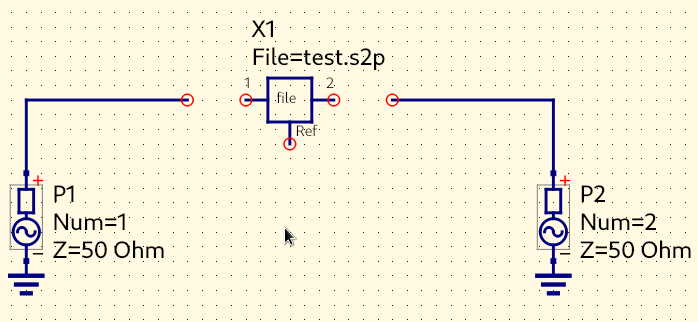

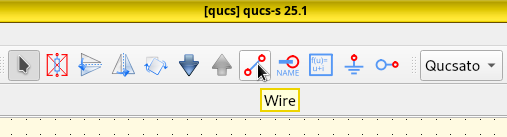

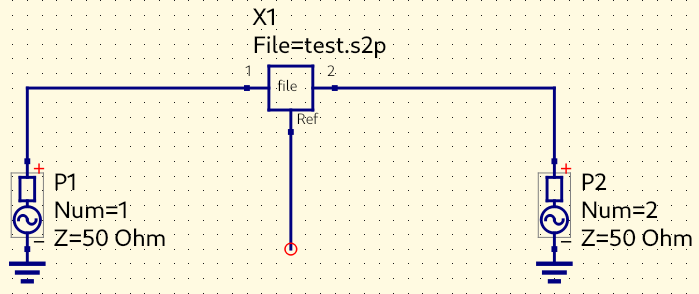

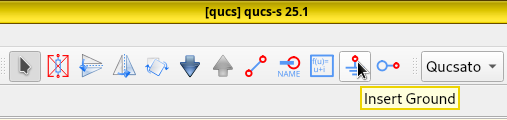

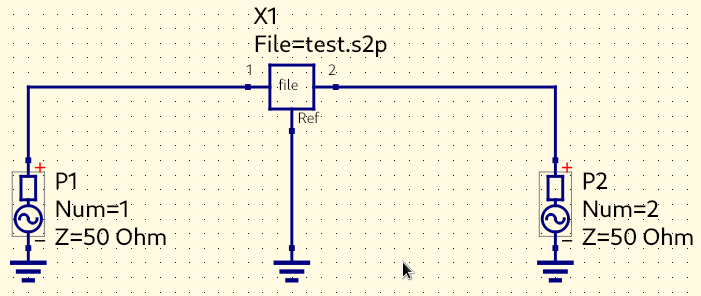

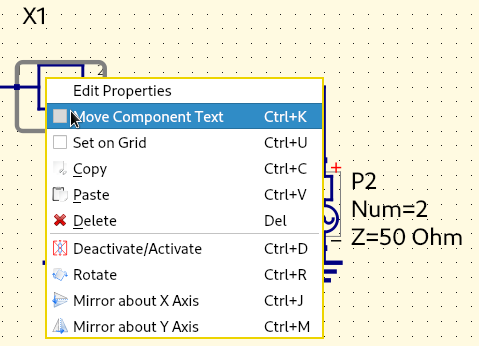

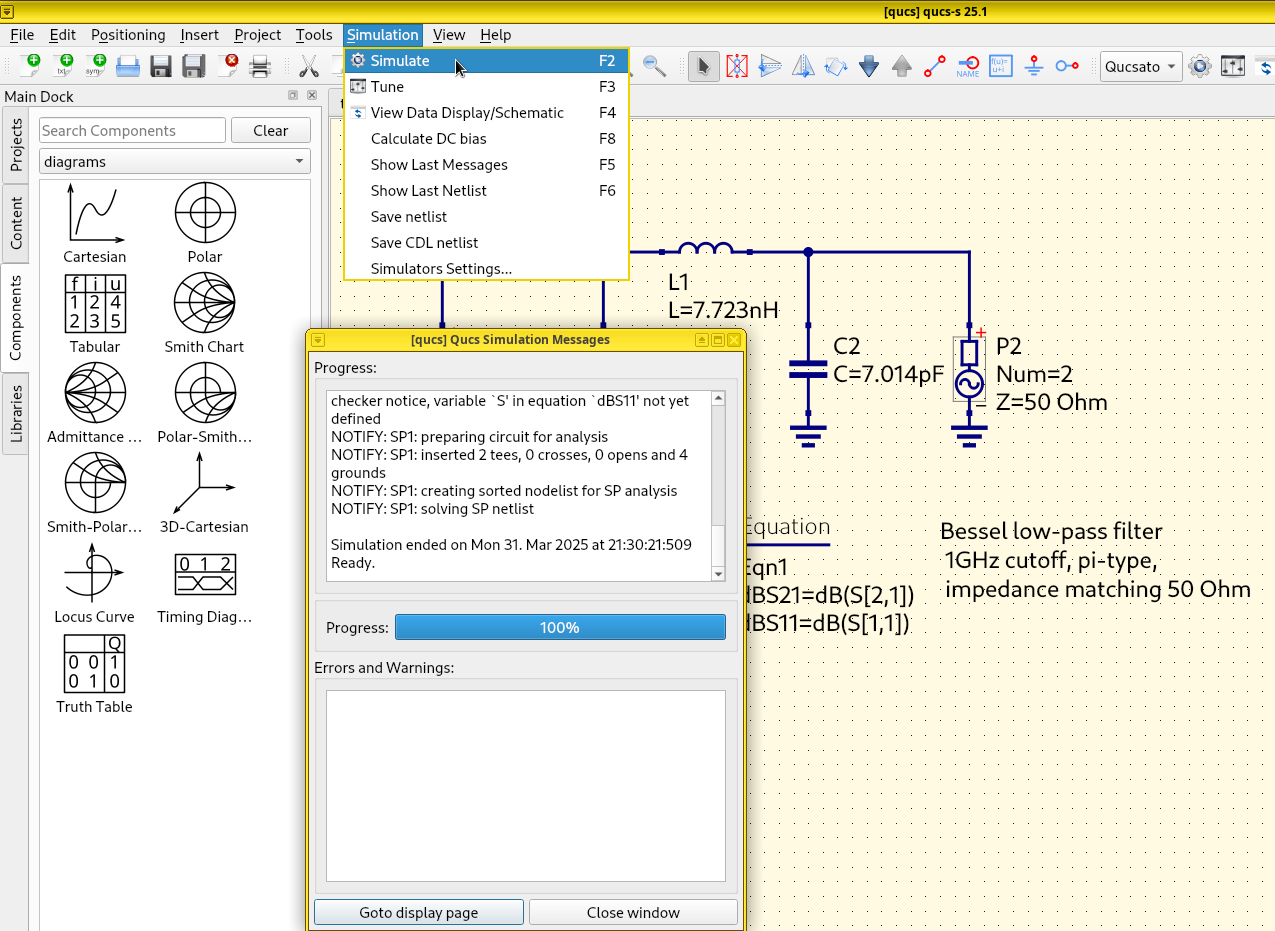

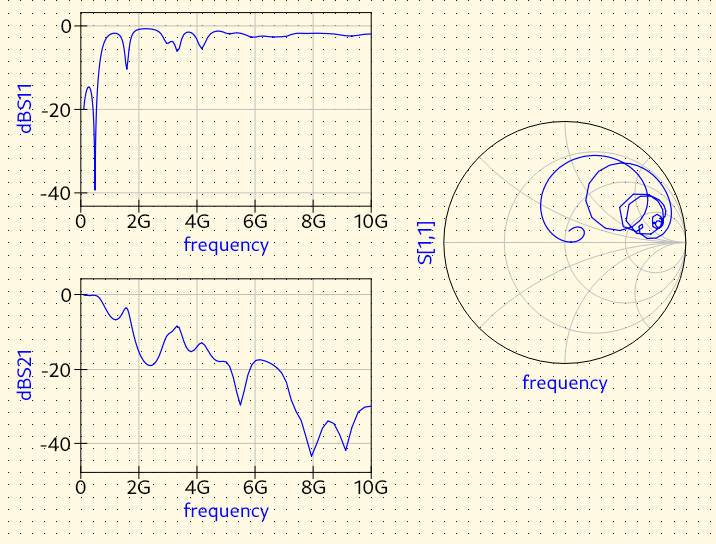

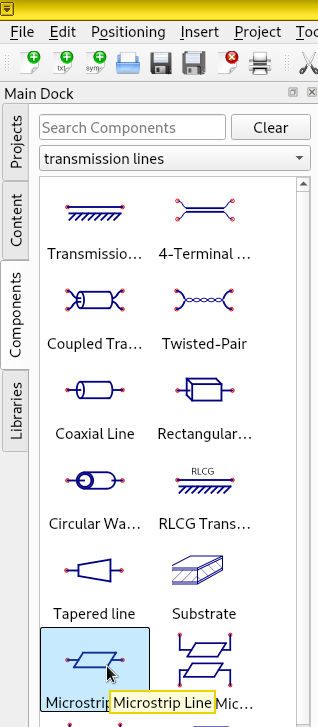

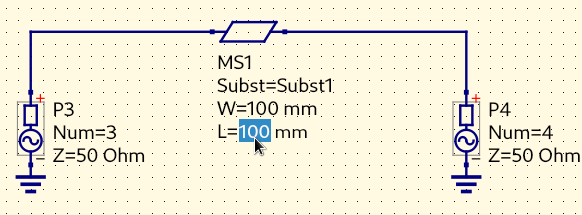

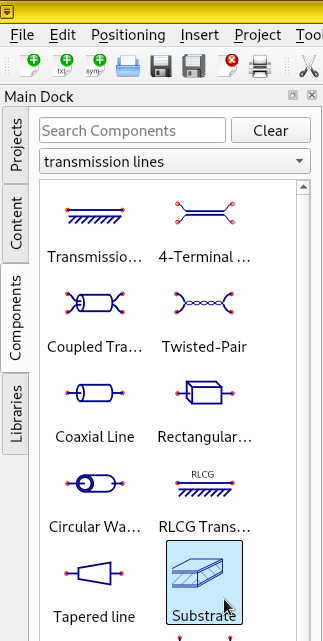

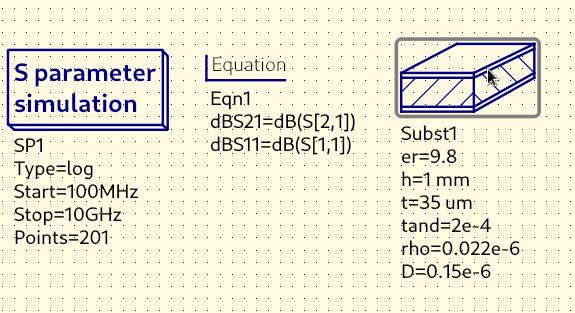

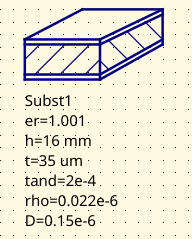

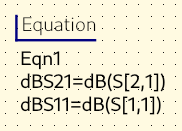

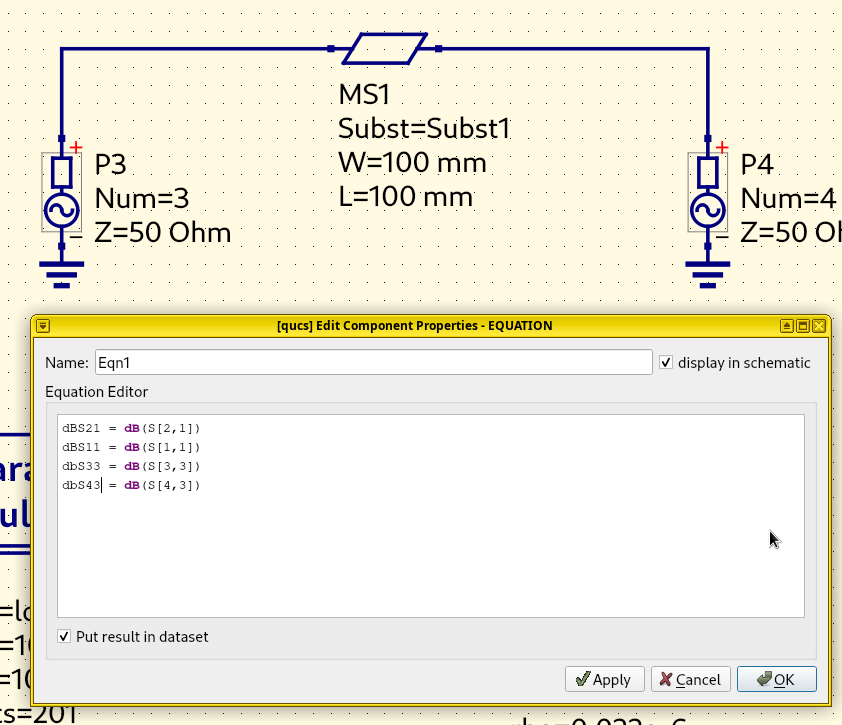

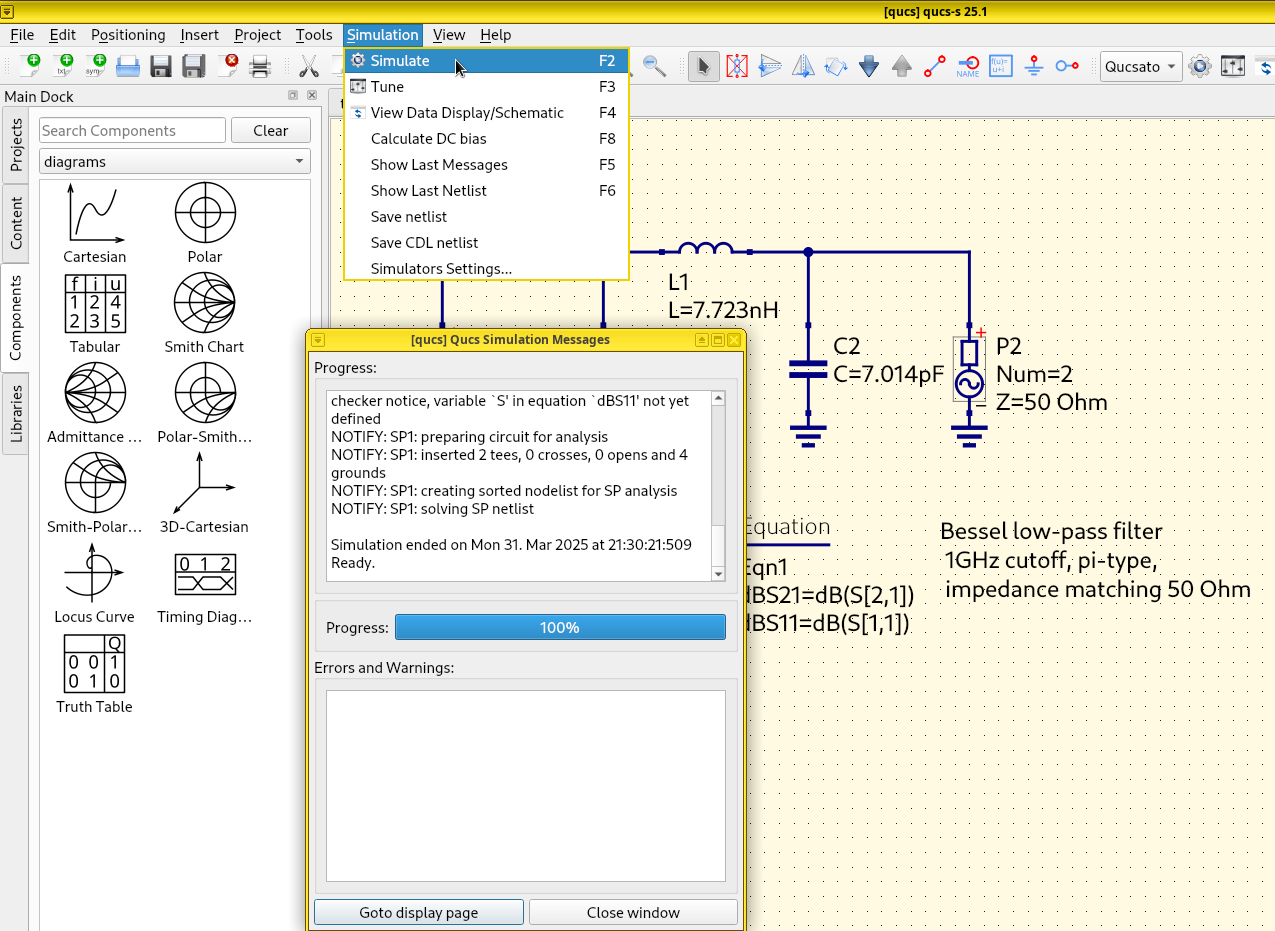

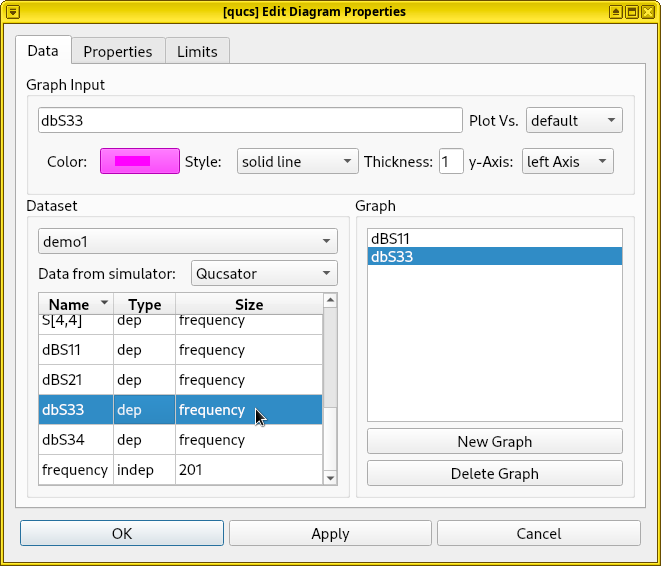

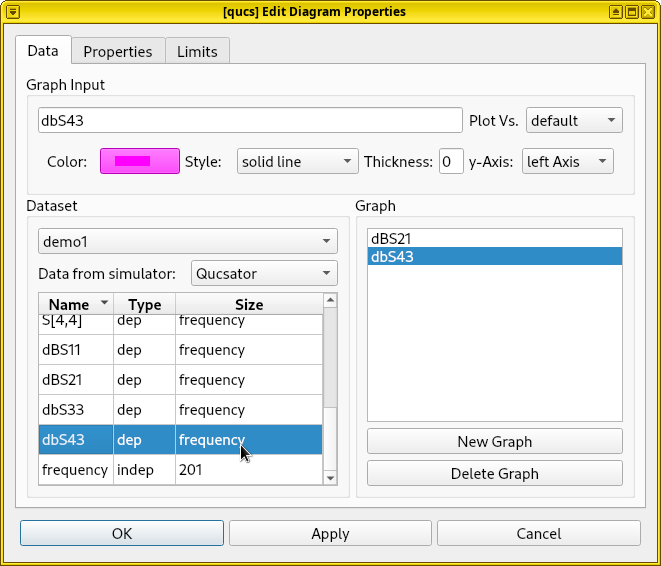

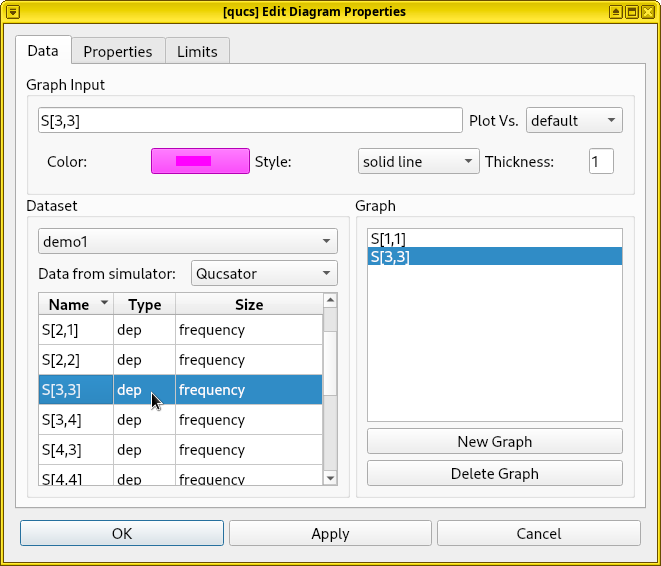

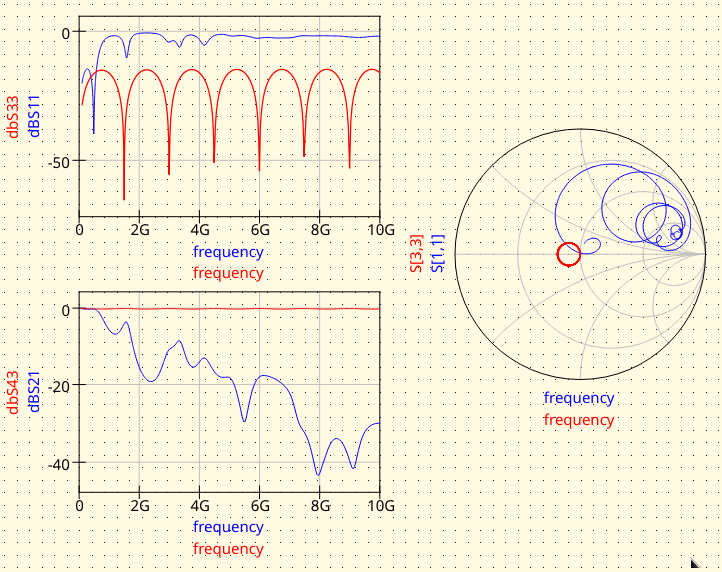

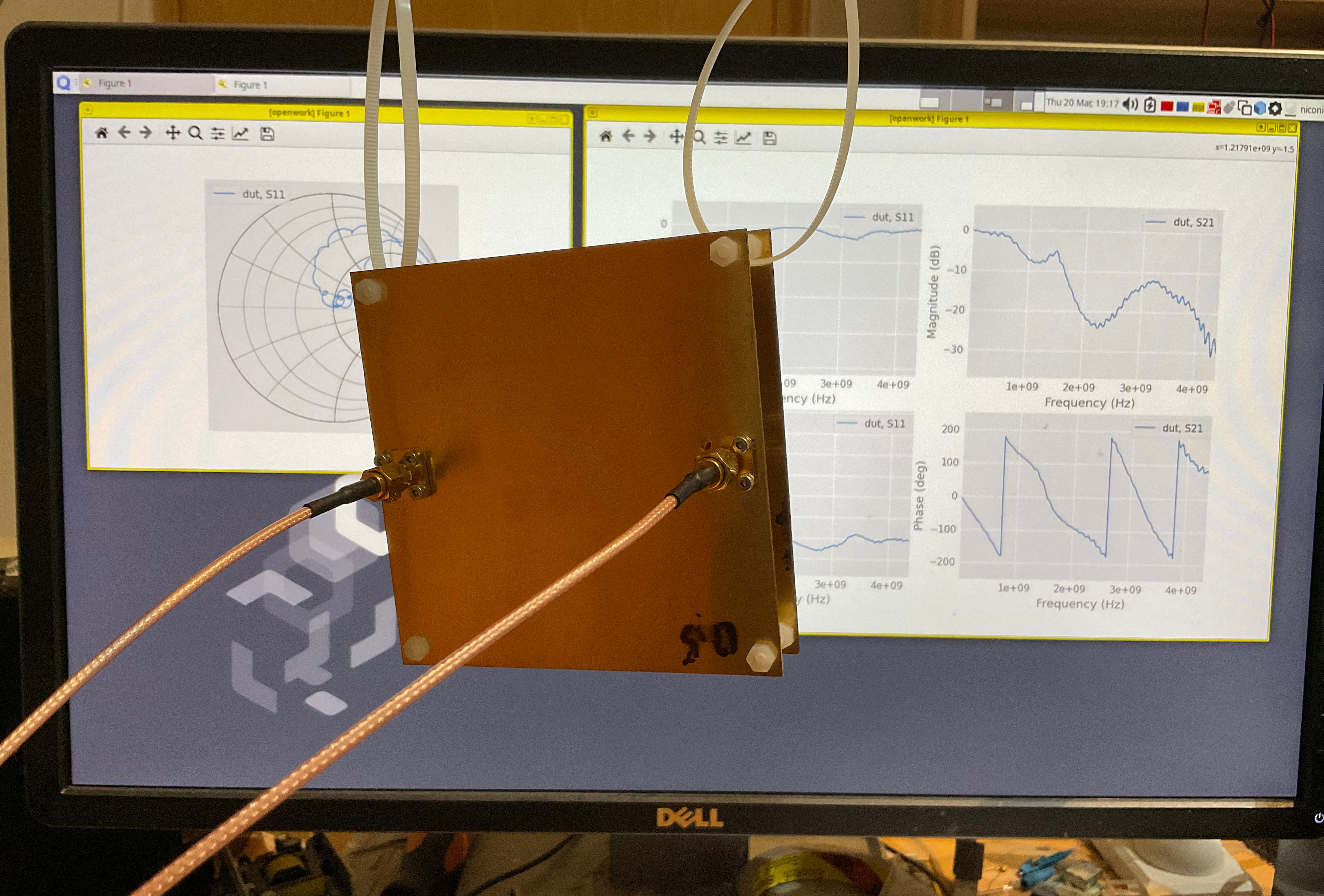

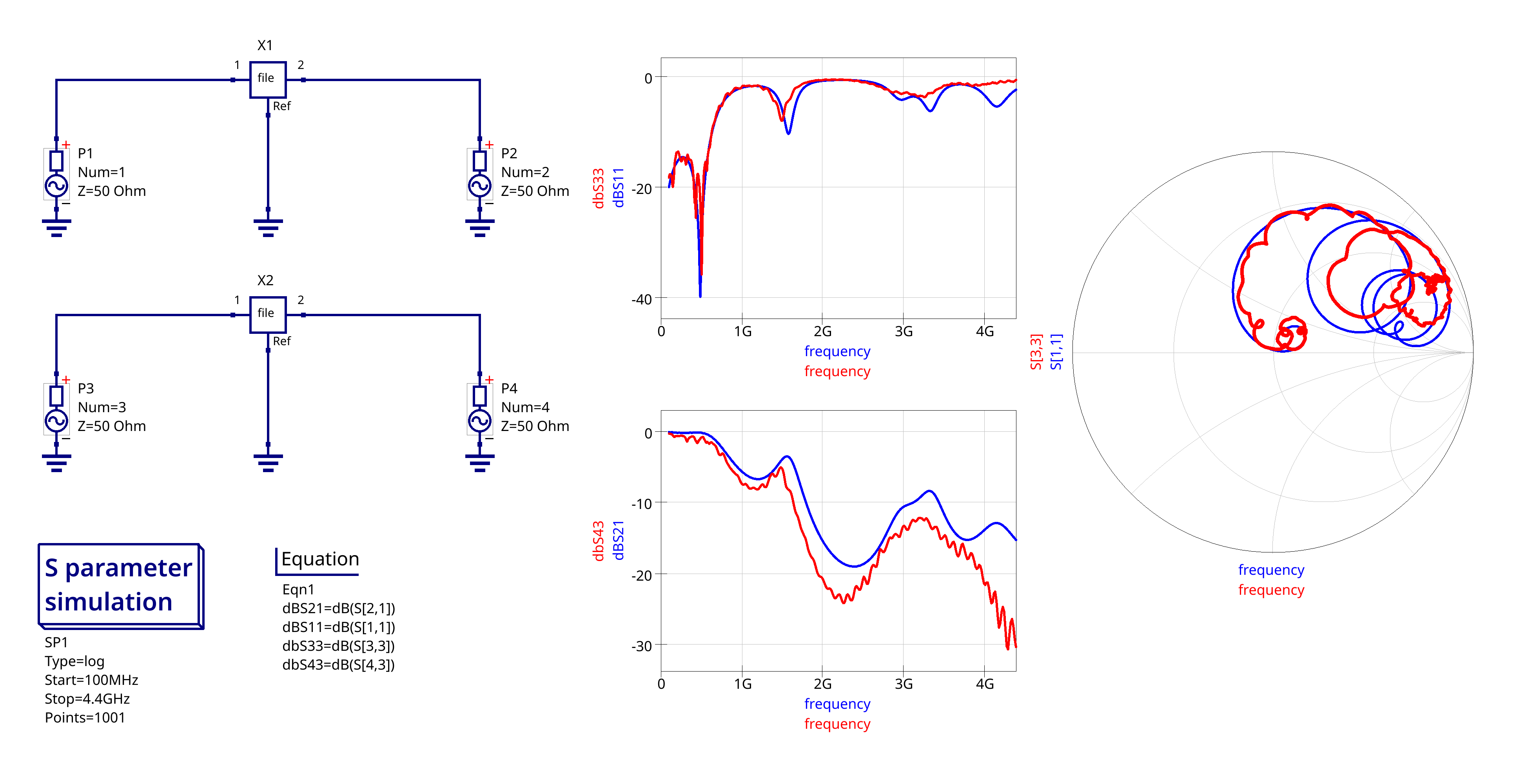

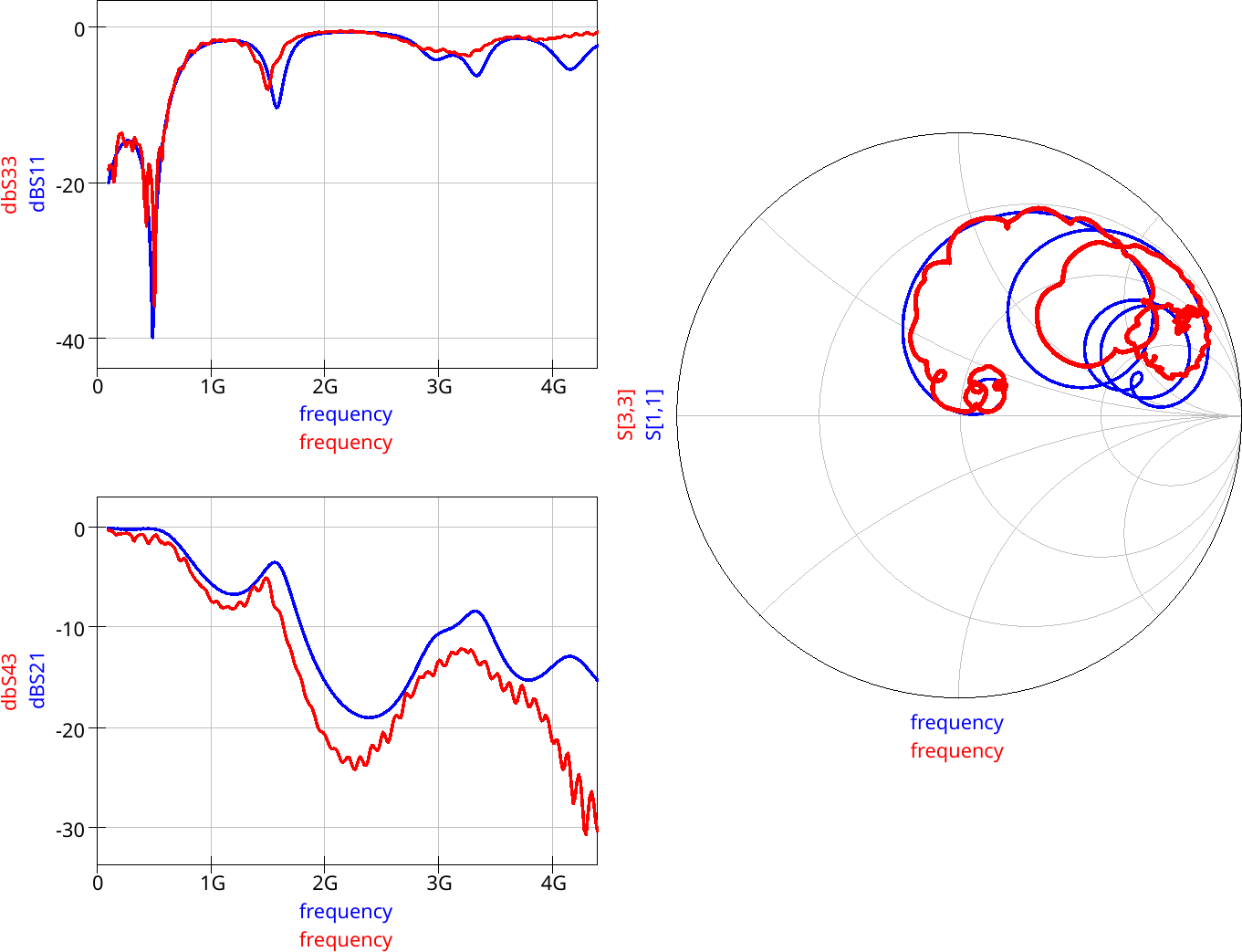

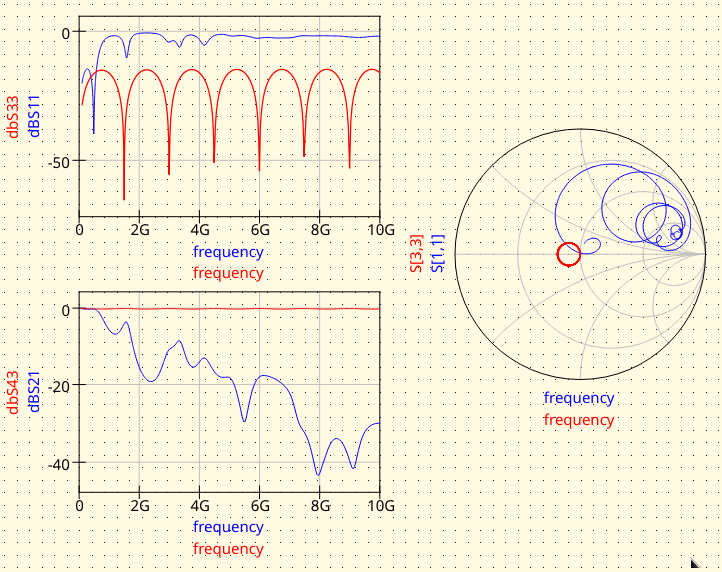

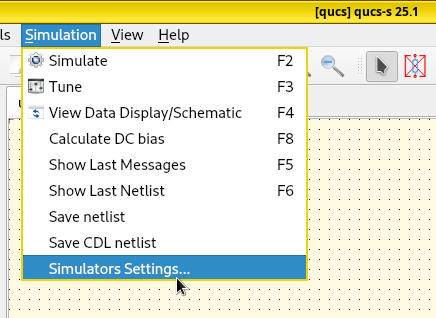

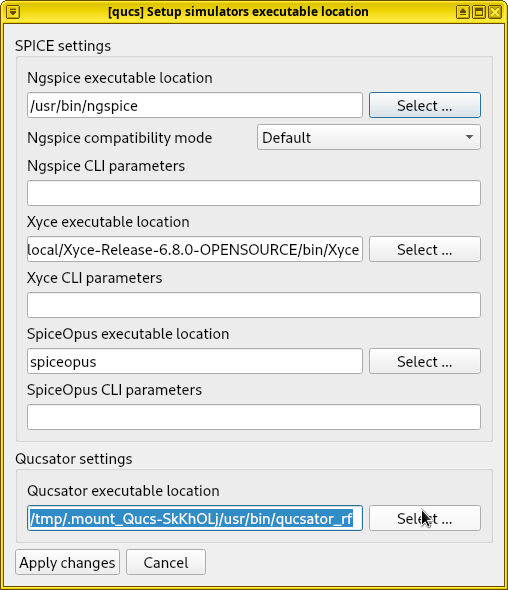

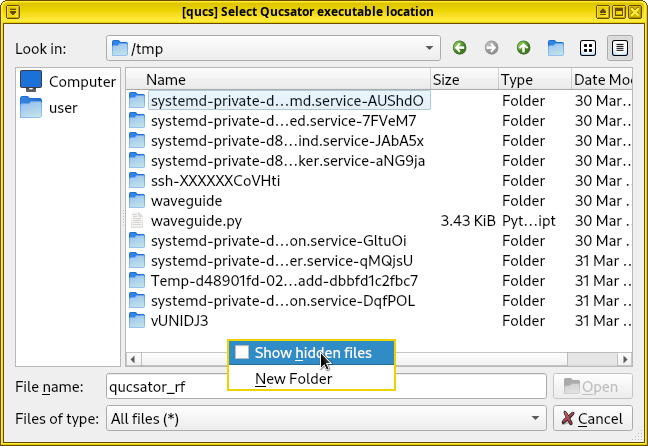

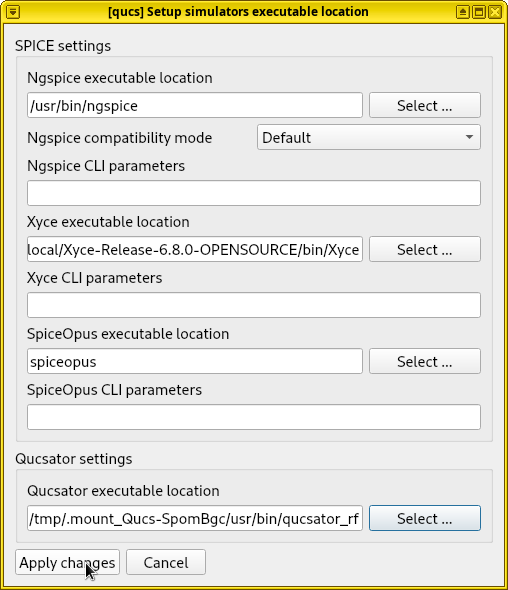

Plot the S-parameters using Qucs-S, compare our results with an ideal microstrip transmission line, and with experimental data.

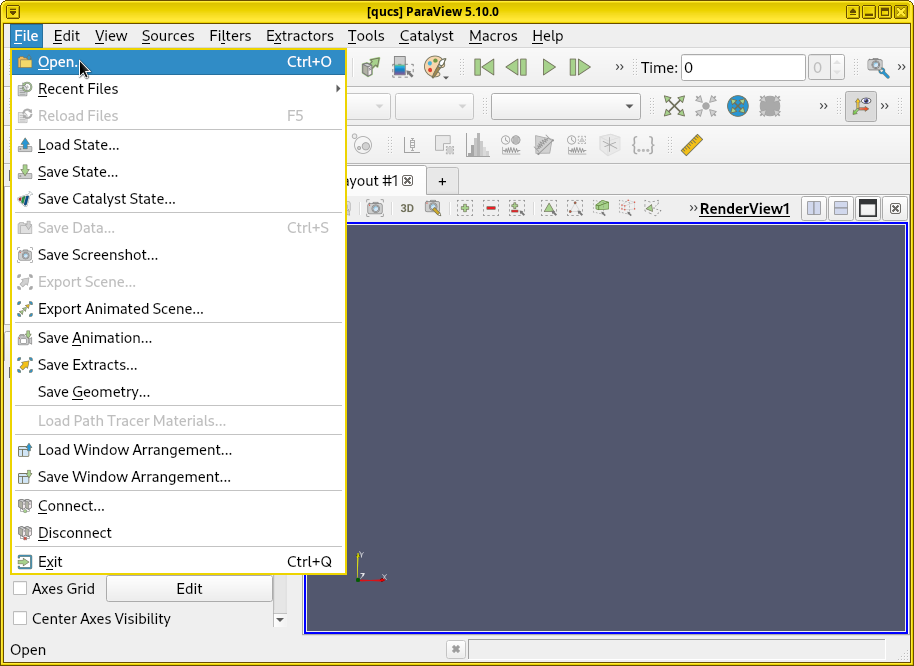

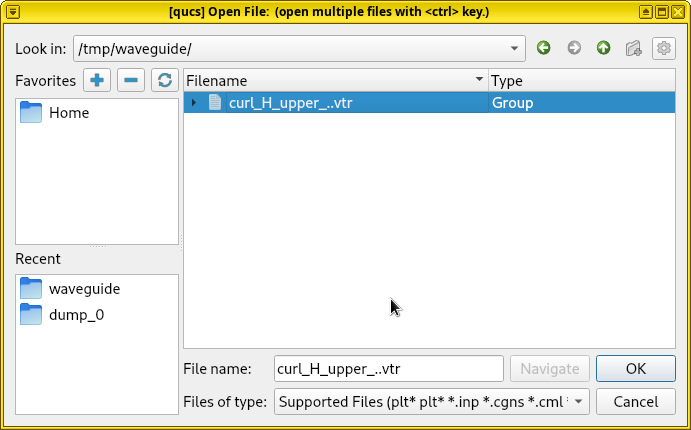

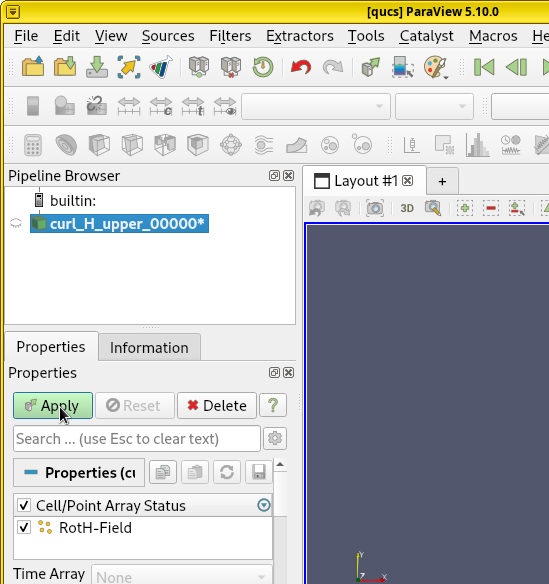

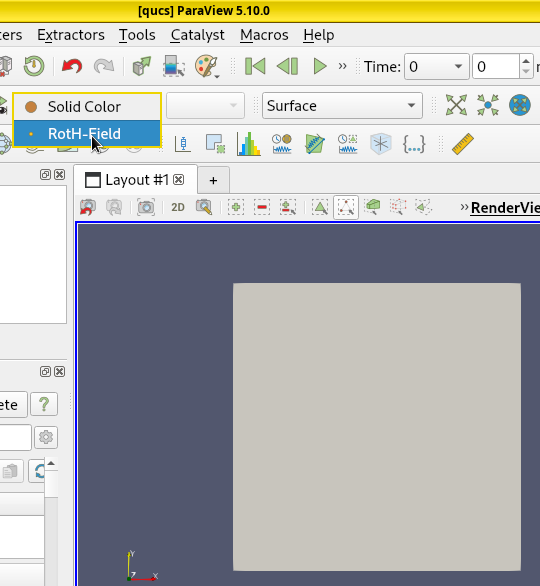

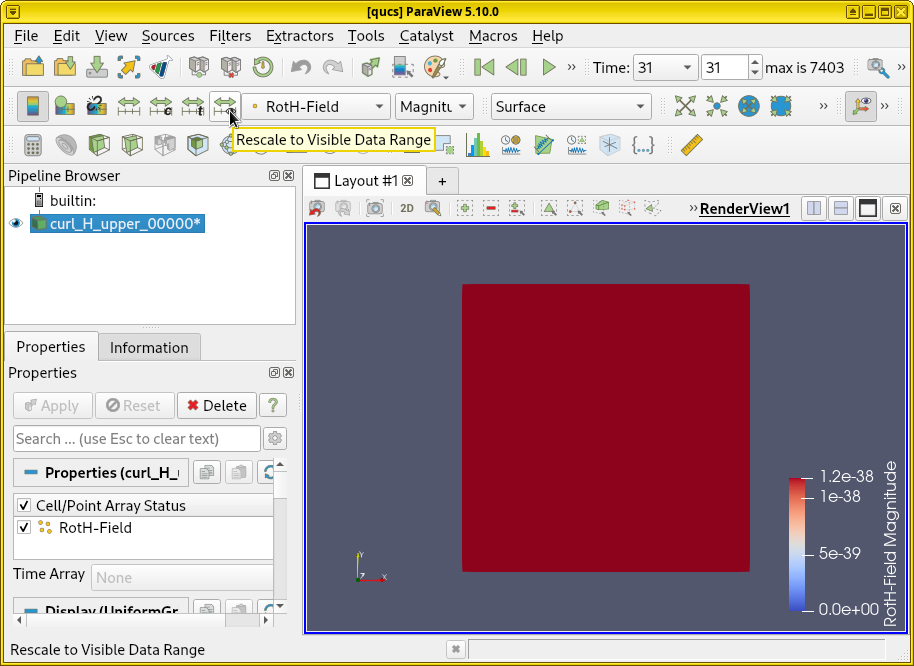

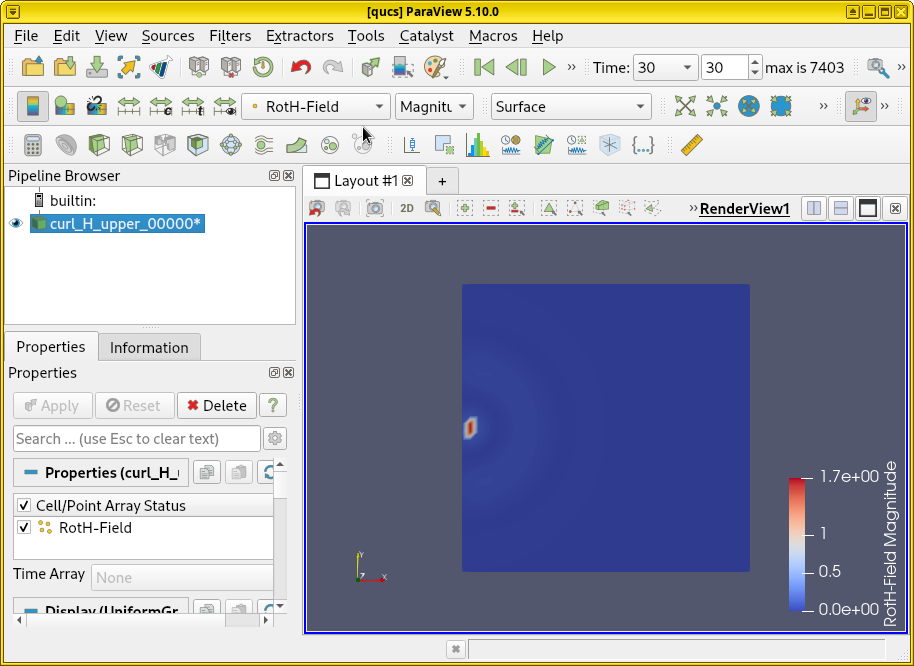

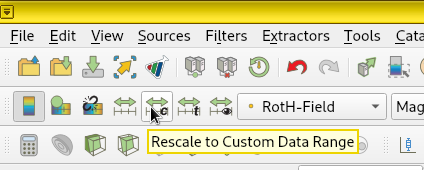

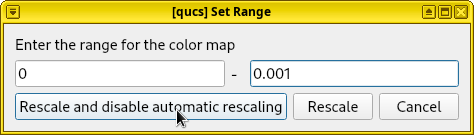

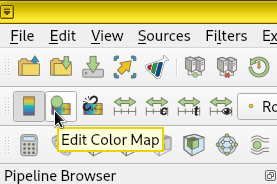

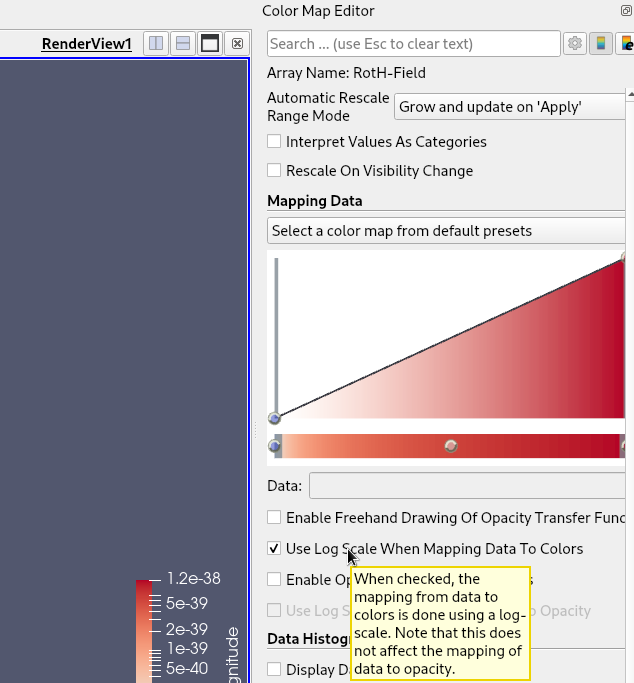

Visualize electromagnetic fields using ParaView.

Coding Standard: Refactor the simulation code with good programming practice in mind, by keeping 3D modeling, simulation, and post-processing as separate functions. This ensures that different simulations can be ran with different parameters in the future.

Problem

A rectangular parallel-plate capacitor in a vacuum is a staple of physics classes, but the physics involved is far more complex than an ideal capacitor in introductory textbooks. In the RF/microwave regime, the signal’s wavelength becomes comparable to or even smaller than the physical size of the capacitor. The plates form a two-conductor transmission line, known as a parallel-plate waveguide.

However, the ideal parallel-plate waveguide is just a simplified model, much like the ideal parallel-plate capacitor. A real, finite-size waveguide still exhibits a fringe field, typically neglected in theoretical treatments. The large plate separation further complicates the situation; it’s easy for the signal to escape from the plates because of radiation loss. This is especially problematic when a signal is injected by a bare wire without a smooth transition - strong reflections occur right at the connector before the signal can even enter the structure.

Multimoding is another challenge - in addition to the familiar signal mode that travels along two-conductor cables (TEM wave), the non-uniform electric field across the plate may allow TE/TM-mode waves to propagate, which are more commonly associated with enclosed, single-conductor waveguides.

Given these complexities, a 3D full-wave field solver like openEMS is the most practical way to simulate the behavior of a real, non-ideal parallel-plate waveguide. It does so by numerically solving Maxwell’s equations, the first principles of electromagnetism.

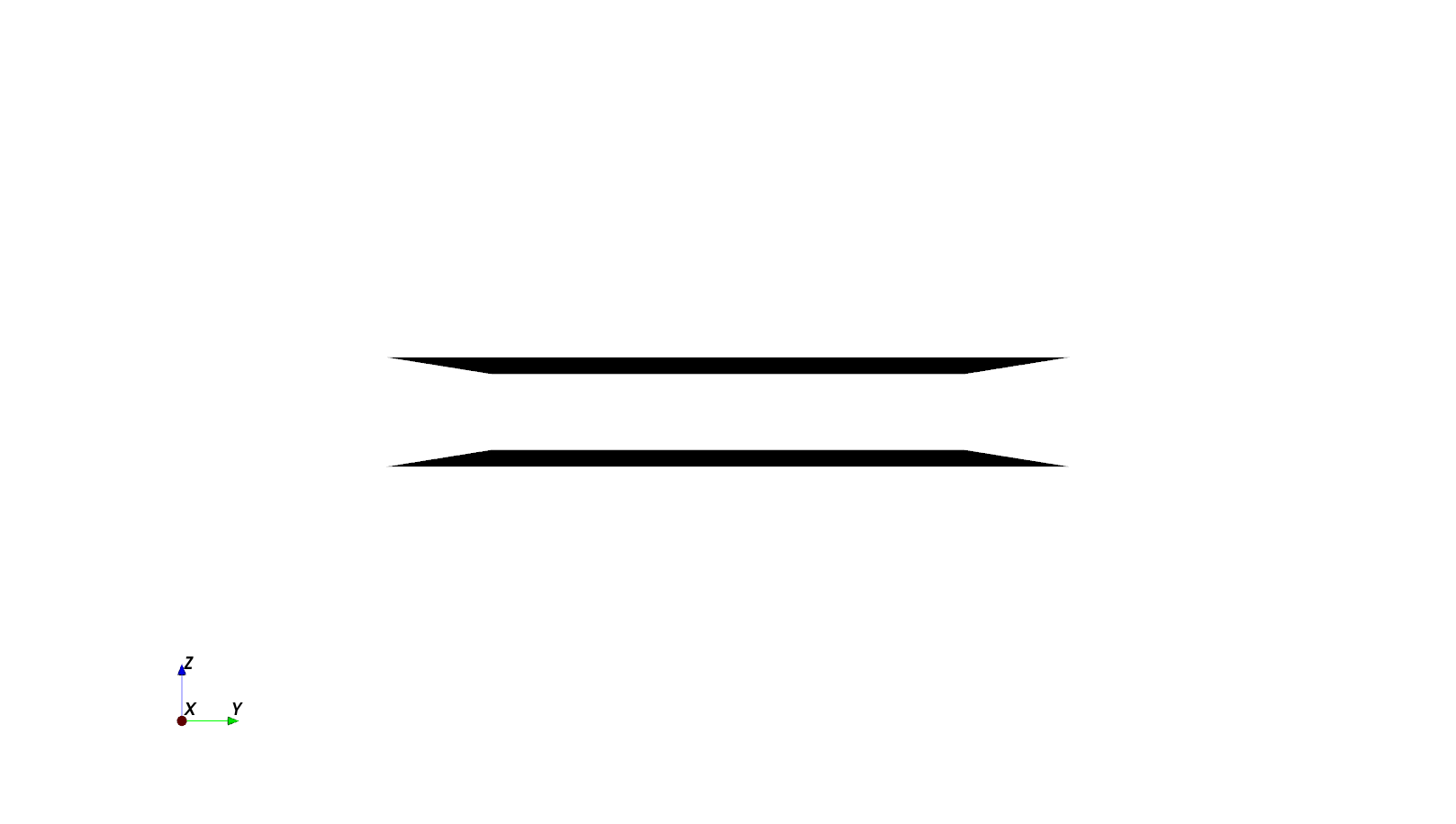

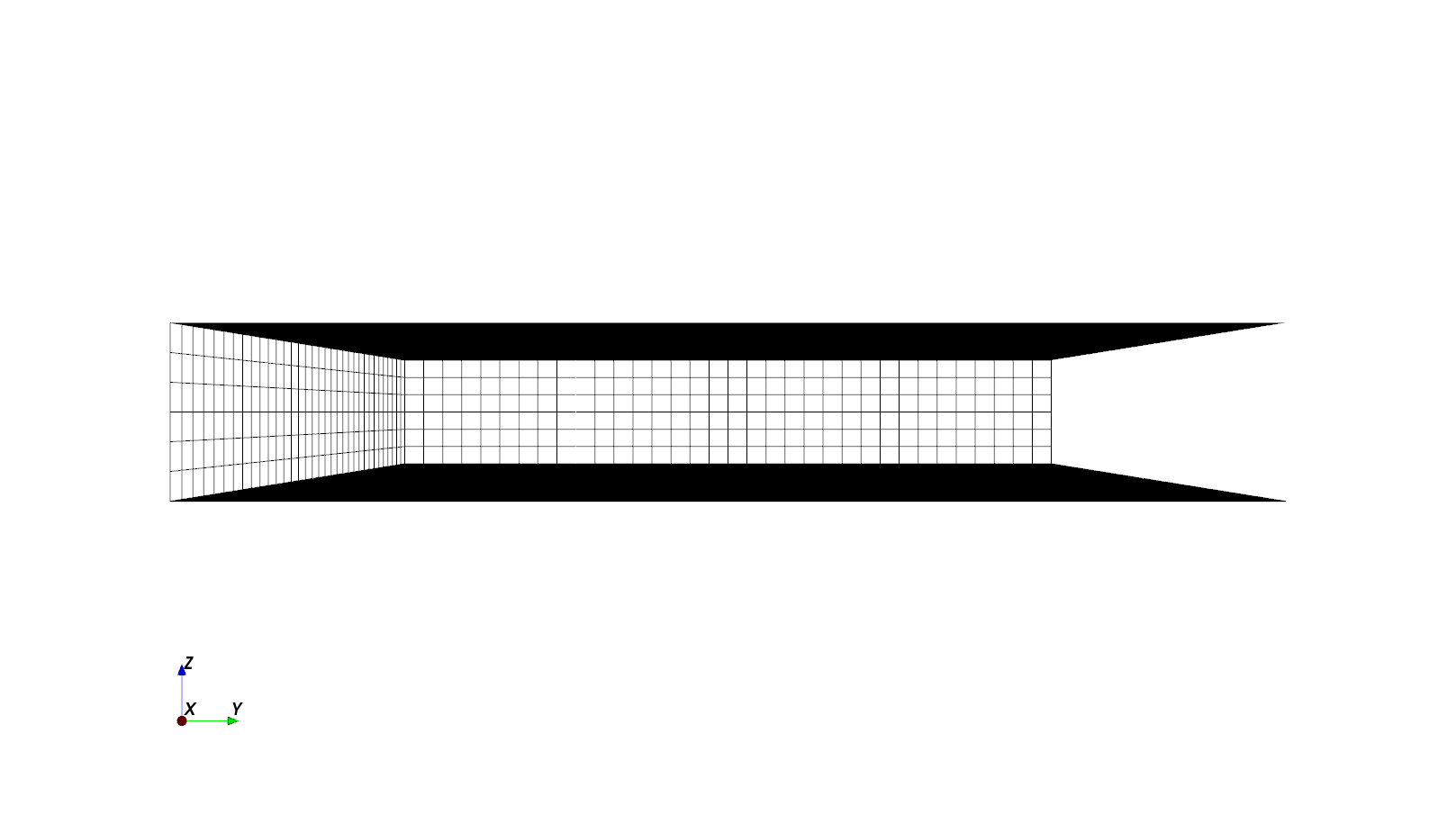

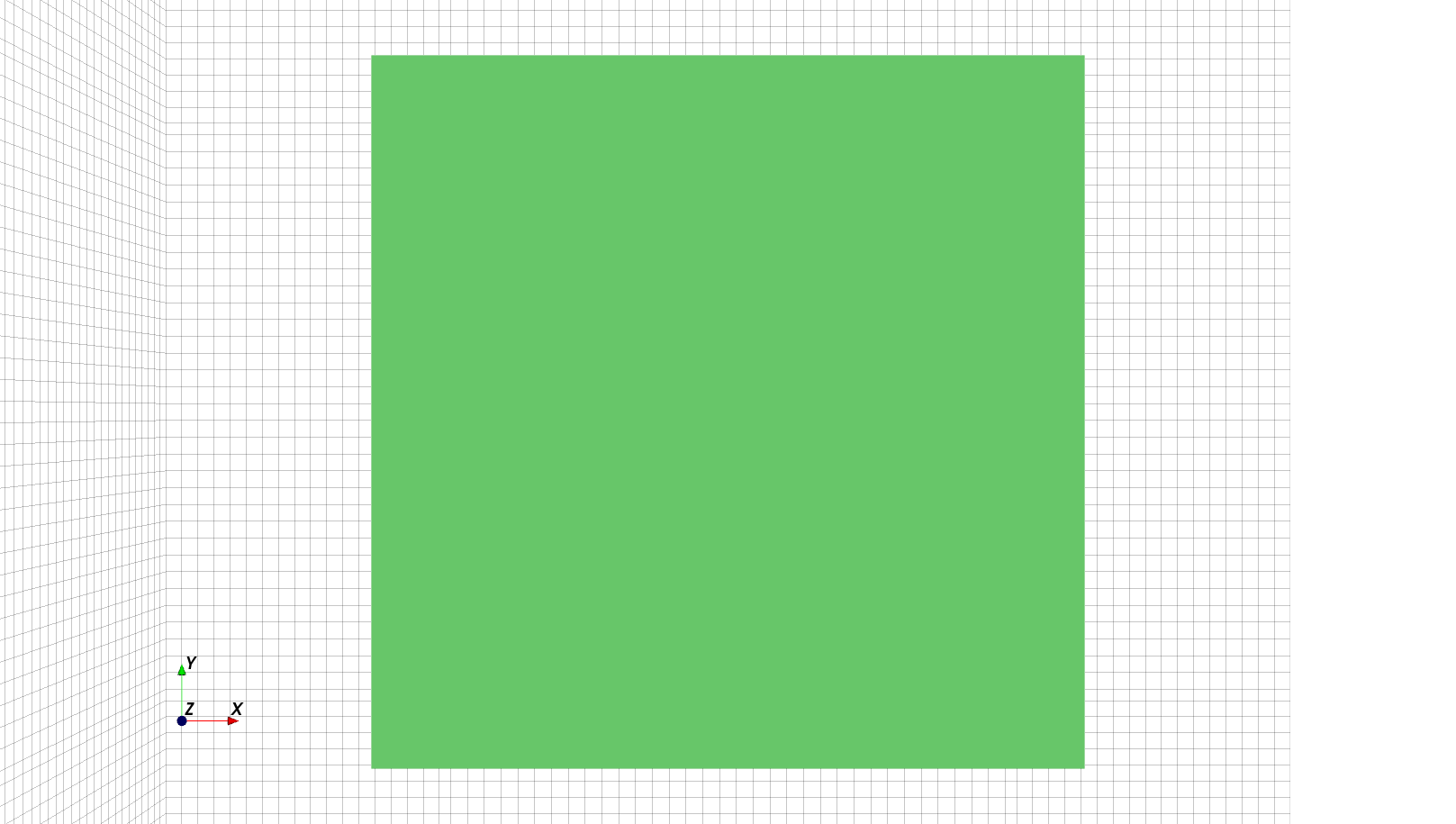

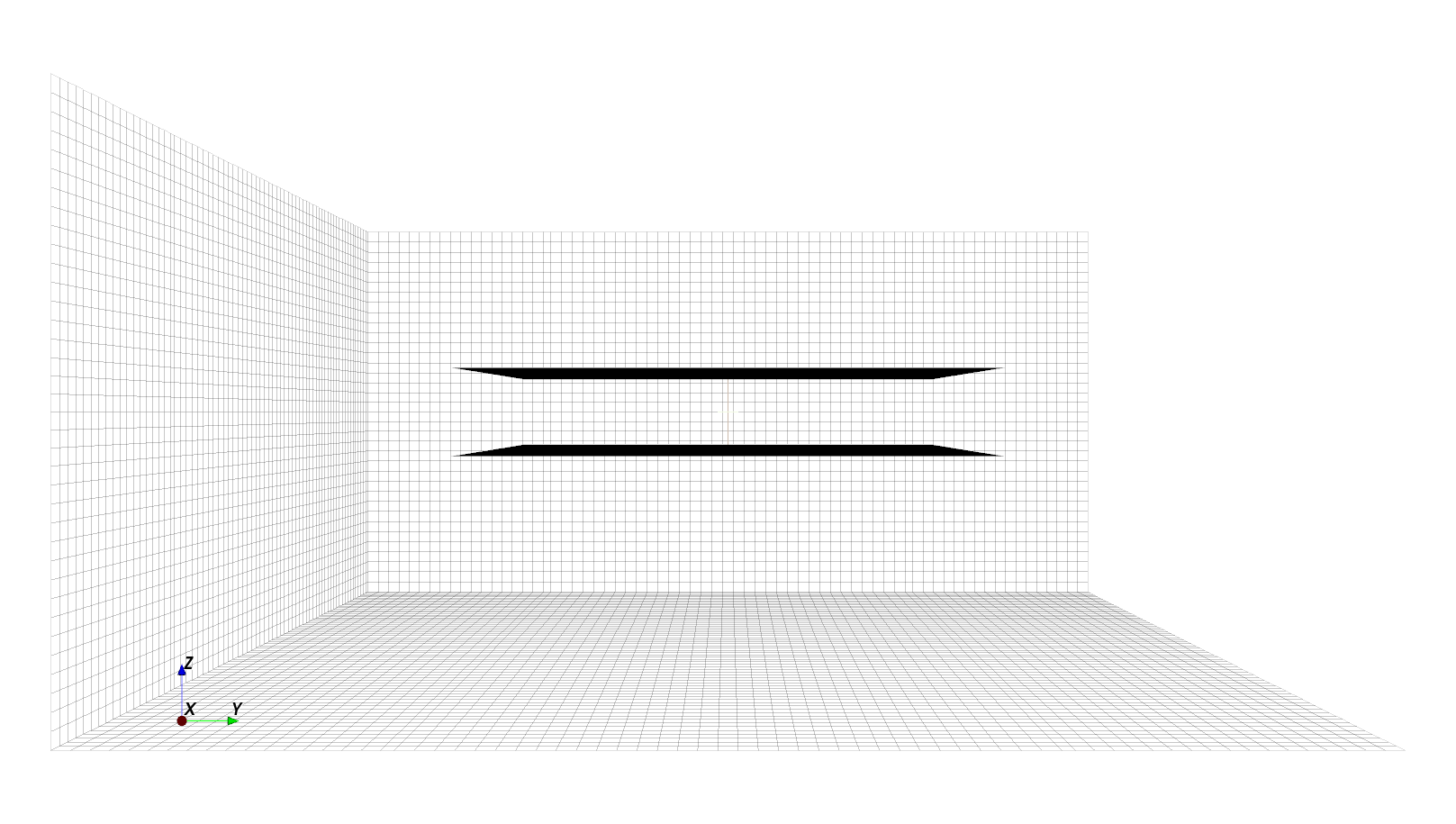

Our task is to find the frequency response of the rectangular parallel-plate waveguide shown below. It’s formed by two metal sheets each measuring 100 mm x 100 mm, assumed perfect without resistance or thickness, separated by 16 mm of vacuum.

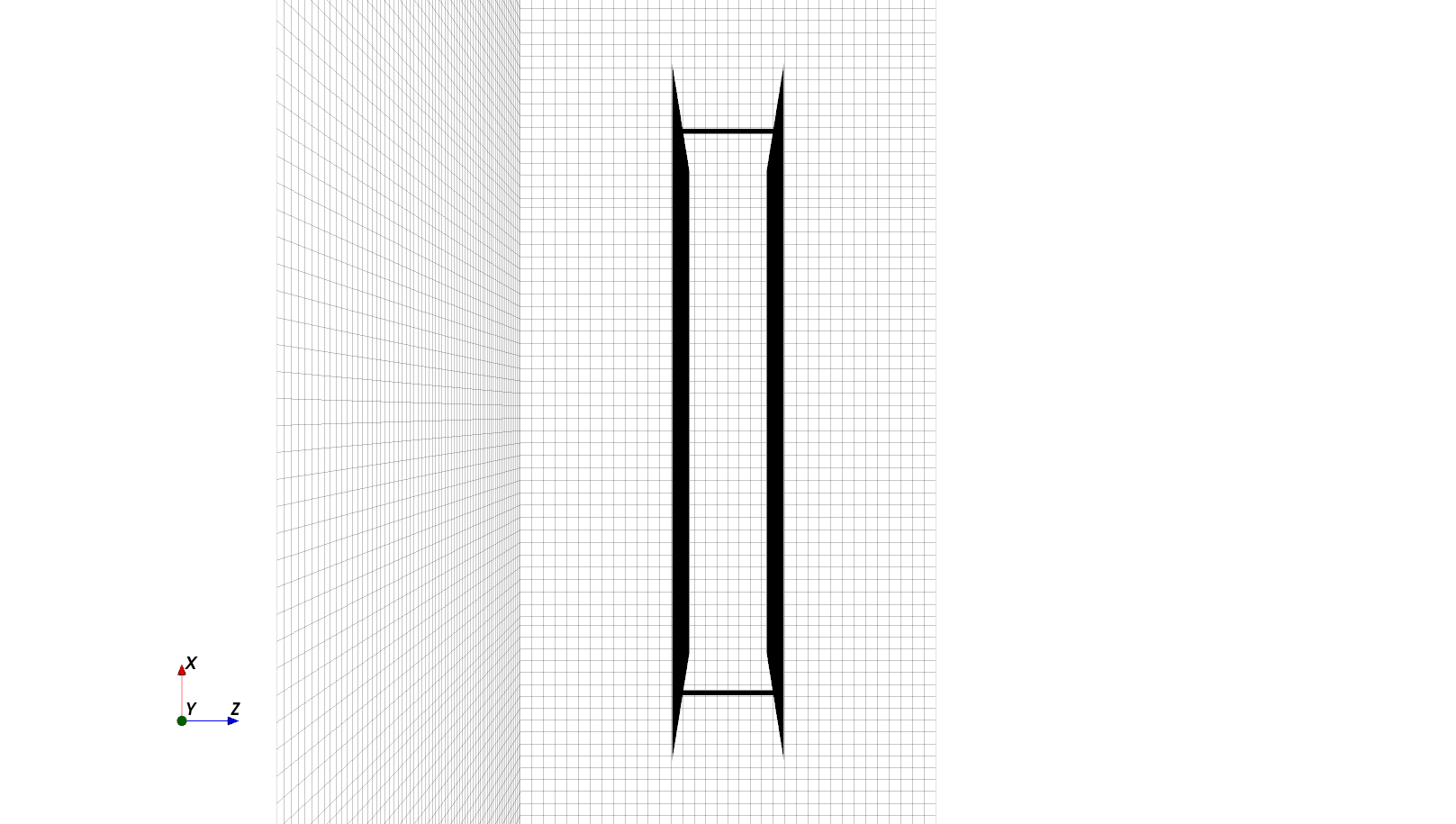

The 2D cross-section of the 3D waveguide is as follows:

Create Conductors

An openEMS simulation always starts by creating a 3D model of the Device-Under-Test

(DUT) using the CSXCAD library. We import the library in Python, and create an empty

structure called csx:

import CSXCAD

csx = CSXCAD.ContinuousStructure()

The next step is to define a material type by creating an material instance,

which can then be used to build an object. Since we’re modeling metal plates

with no resistance, we use the CSXCAD function

AddMetal() to obtain an instance of a Perfect

Electric Conductor (PEC):

# Create an instance of material named "plate".

# AddMetal() creates a Perfect Electric Conductor.

metal = csx.AddMetal('plate')

Note

Internally, PEC is implemented by forcing the tangential electric field in this region to be zero, which is characteristic of an ideal conductor that can’t be penetrated by electric field lines. If resistive losses are unimportant, one can use PEC rather than a realistic material model for simplicity and efficiency.

To add a general material (defined by a permittivity, permeability, electric

conductivity, magnetic conductivity) such as dielectrics, use

AddMaterial(). In principle, it works for

3D metals as well. But thin metal sheets are challenging in FDTD: to capture

effects like surface current (skin effect) requires an impractically high

resolution mesh. Thus, it’s recommended to use

AddConductingSheet() which mimics the

resistive loss in metals using a simplified model that still treats metals

as zero-thickness 2D planes, modeling the observed loss rather than the full

physics.

In the next step, we build a box using our material “metal”, using the

AddBox() function. It accepts two 3D

coordinates to specify the region occupied by the box.

Our waveguide plates are 100 mm x 100 mm rectangular metal sheets, separated by a 16 mm vacuum (i.e. empty space). Following the common CAD conventions, we center the plates around the origin. Thus, for the upper plate, both its X and Y coordinates are (-50, 50). Their Z coordinates are -8 and 8 respectively, which means these metal plates have no thickness:

# Build two 3D shapes from -50 to 50 on the X/Y axes, located at Z = -8

# and Z = 8 respectively. Note that the starting and stopping Z coordinates

# of each plate are the same, resulting in metal plates with zero thickness.

metal.AddBox(start=[-50, -50, -8], stop=[50, 50, -8]) # lower plate

metal.AddBox(start=[-50, -50, 8], stop=[50, 50, 8]) # upper plate

Now it’s a good time to take a look at the structure that we’ve just created

by saving the CSXCAD structure as a file. It’s best to keep a call to

Write2XML() always at the bottom of a script

during development, so that we can readily review the model during development:

import sys

import pathlib

# find the directory of the script itself

filepath = pathlib.Path(__file__)

# create a directory named after the script, but without ".py"

simdir = filepath.with_suffix("")

simdir.mkdir(parents=True, exist_ok=True)

# find the filename of the script itself, and replace ".py" with ".xml"

xmlname = filepath.with_suffix(".xml").name

# concat two paths

xmlpath = simdir / xmlname

csx.Write2XML(str(xmlpath)) # convert Path object to string

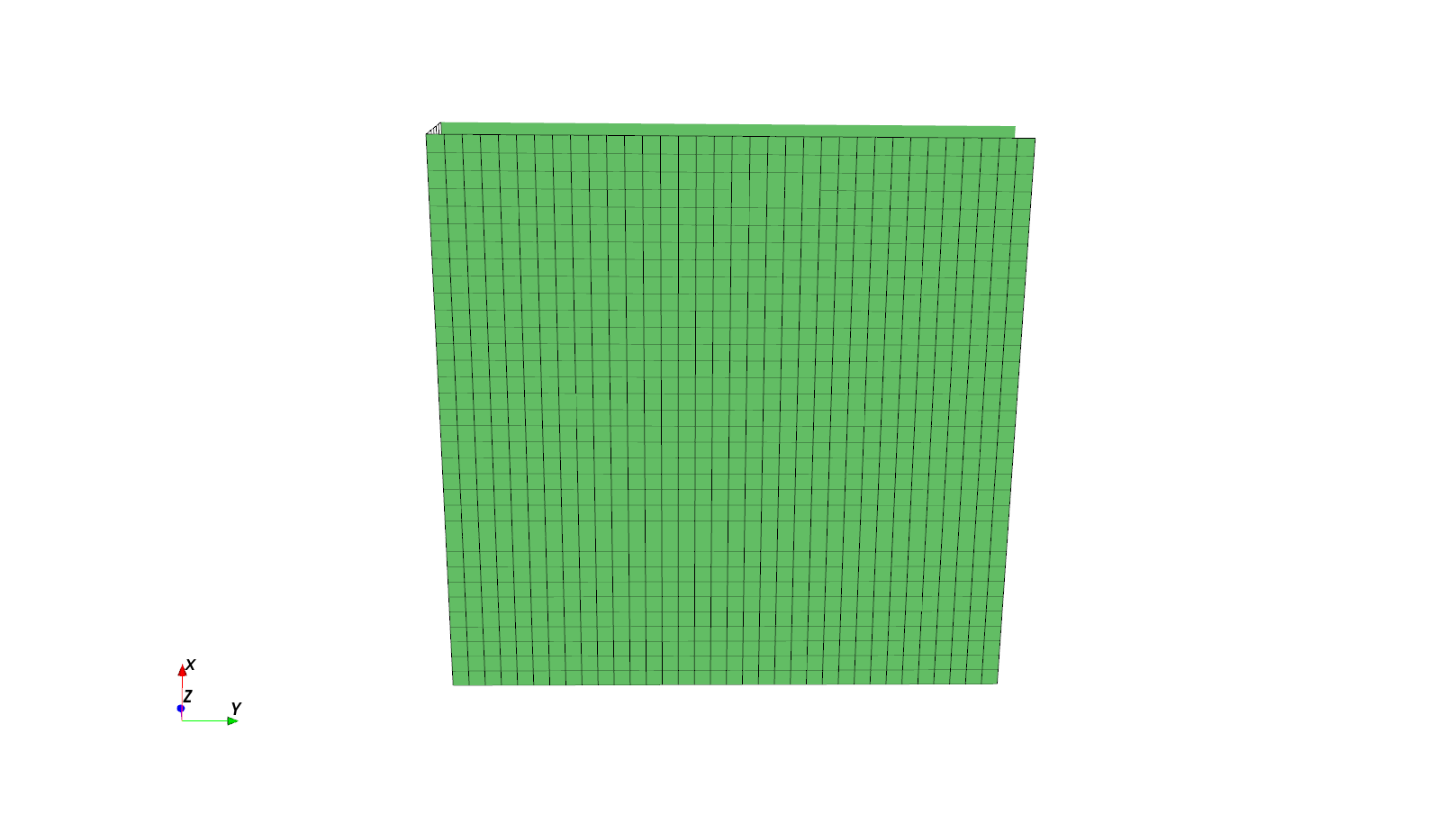

Once saved by executing our Python script, one can open the file via AppCSXCAD to visualize the model:

$ AppCSXCAD Parallel_Plate_Capacitor_Waveguide.xml

Important

If you’re using Wayland, AppCSXCAD may not work correctly, see Notes for Wayland Users.

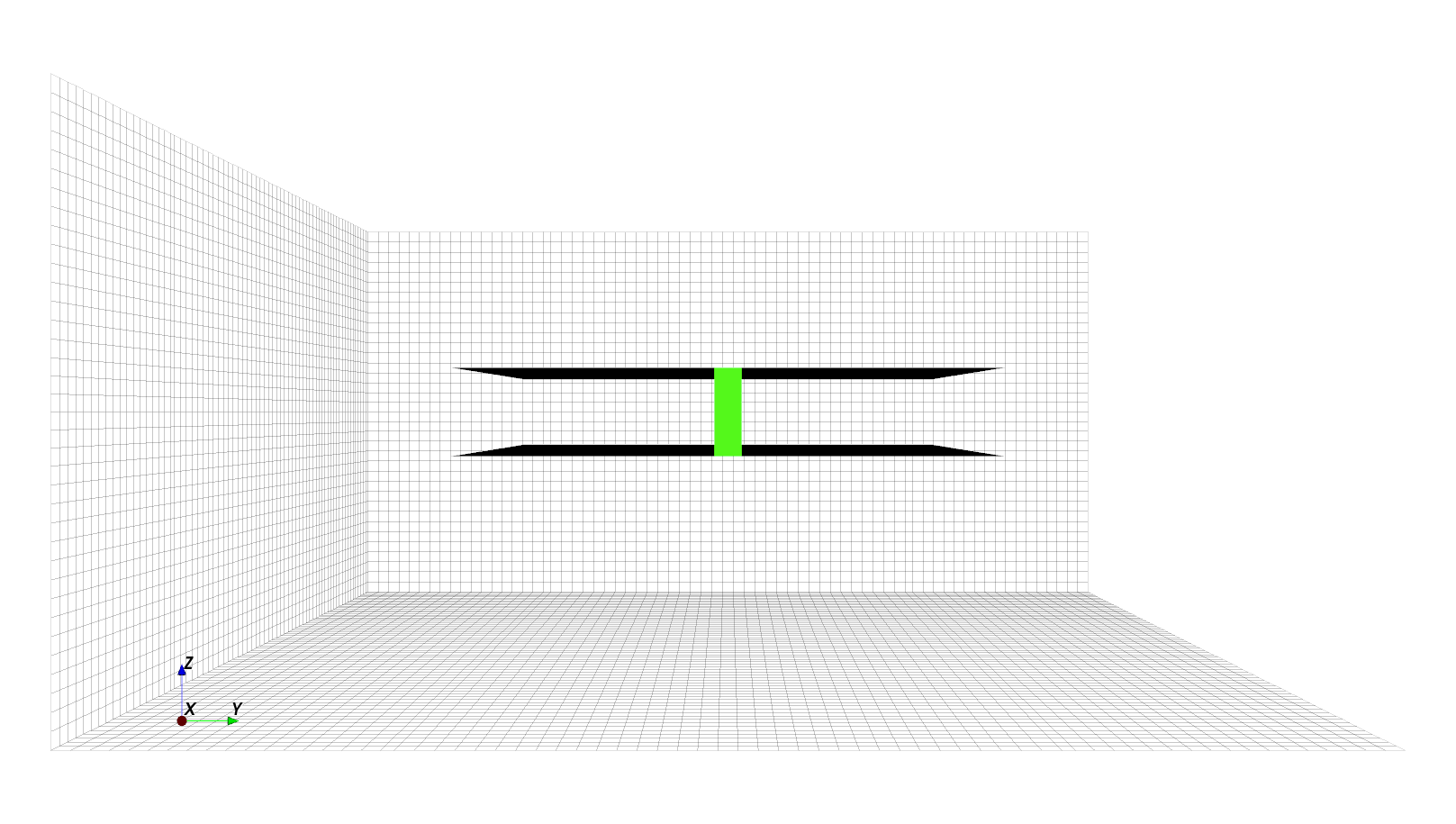

One can inspect the model by mouse drags, looking at it from different camera angles. Here’s the XY and YZ cross-sections of the correct 3D model:

Requirements for the Mesh

At this point, the 3D object itself is materialized. In the next step, we create a mesh to partition the continuous 3D box into discrete rectangular cuboids. In the Finite-Difference Time-Domain (FDTD) algorithm, these cuboids discretize the 3D space and form the basic unit of electromagnetic calculations. These are known as Yee cells (named after Kane S. Yee’s 1966 algorithm).

General Requirements

In general, the mesh must satisfy four requirements:

Frequency Resolution. Its interval must be small enough to resolve the shortest wavelength (highest frequency component) of the signal, so that electromagnetic field details are not missed. Thus, we need several cells per wavelength.

Spatial Resolution. Its interval must be small enough to resolve the shapes of the simulated structure, so that small details of the structure are not missed. Thus, we need at least a few cells around the important shapes (such as the waveguide plates) of the structure. openEMS uses a rectilinear mesh with variable spacing. To save time, only use a fine mesh interval around details on a structure; use a coarse mesh for the rest.

Smoothness. Its interval should change smoothly, not by a sudden jump. It’s recommended that the mesh spacing vary by no more than a factor of 1.5 between adjacent lines.

1/3-2/3 Rule. The edges of a conductor have singularities with strong electric field. To improve FDTD accuracy, ideally, around the metal edge, the metal should occupy 1/3 of a cell, while the vacuum or insulator occupies 2/3 of a cell. More on that later.

As a rule of thumb, we want a mesh resolution of at least:

Note

This is the same “1/10 wavelength” rule of thumb used for determining whether transmission line effects are significant in a distributed circuit.

The relationship between wavelength and frequency is:

in which \(\lambda\) is the wavelength of the electromagnetic wave in meters, \(v\) is the speed of light in a medium, in meters per second, and \(f_\mathrm{max}\) is the highest frequency component of the signals used in simulation.

The speed of light in a medium is given by:

in which \(c_0\) is the speed of light in vacuum, \(\epsilon_r\) is the relative permittivity of the medium (in engineering, it’s sometimes also denoted as a material’s dielectric constant \(D_k = \epsilon_r\)). The \(\mu_r\) term is the medium’s relative permeability, which is usually omitted in engineering for the purpose of signal transmission. Most dielectrics (like plastics or fiberglass) in cables are non-magnetic - unless one is dealing with inductors or circulators.

In vacuum, \(\epsilon_r = 1\) and \(\mu_r = 1\) exactly.

Courant-Friedrichs-Lewy (CFL) Criterion

In general, the CFL criterion governs the stability of FDTD calculations. It states that the simulation timestep can’t be larger than:

where \(v\) is the wave speed, \(\Delta x\), \(\Delta y\), \(\Delta z\) are the distances between mesh lines.

This creates a peculiar limitation: to resolve the smallest mesh cell, one must use a small timestep regardless of frequency.

Even for simulations at low frequencies, as long as the simulated structure has small features (i.e. mesh distance is short), we must use very small timesteps, advancing the simulation only a few nanoseconds per iteration. Under 100 MHz, at the bottom of the VHF band or in the HF band, the required number of iterations becomes impractically large. This means openEMS (and other textbook FDTD solvers with explicit timestepping) is unsuitable if there’s a large mismatch between the signal wavelength and the physical size of the structure, such as a 10 cm circuit board operating at 1 MHz, where the wavelength is 300 m in vacuum.

Note

In openEMS, you only need to define an appropriate mesh.

There’s no need to calculate the required timestep size,

By default, openEMS uses a modified timestep criterion

named Rennings2, not CFL. Rennings2 improves timestep

selection in non-uniform meshes, but the general limitation

(explained using CFL) still applies. Rennings2 is derived

in an unpublished paper 11,

see SetTimeStepMethod() for details.

If you really need small cells (e.g. to resolve some important feature of your structure) you will have to live with long execution times, or perhaps FDTD is not the right method for your problem. As a workaround, one may also try extracting the circuit parameters using a higher signal frequency, then using those equivalent-circuit parameters in a low-frequency simulation with a general-purpose linear circuit simulator.

Create a Mesh

Obtain the Mesh Object

We obtain the mesh object by calling GetGrid()

to manipulate it further, and set its unit of measurement to 1 mm (1e-3 meters).

This will be used as the base unit of all coordinates:

mesh = csx.GetGrid()

unit = 1e-3

mesh.SetDeltaUnit(unit)

Decide the Upper Frequency and Mesh Resolution

Let’s pick an arbitrary lower frequency of 100 MHz and an upper frequency of 10 GHz. Based on the previous analysis, one can calculate the desired mesh resolution via the following code:

import math

from openEMS.physical_constants import C0

f_min = 100e6 # post-processing only, not used in simulation

f_max = 10e9 # determines mesh size and excitation signal bandwidth

epsilon_r = 1

v = C0 / math.sqrt(epsilon_r)

wavelength = v / f_max / unit # convert to millimeters

res = wavelength / 10

A Simple But Flawed Mesh

Now, the most straightforward way of meshing the model is to draw some lines

in the [-50, 50] range on the X and Y axes, and some lines in the [-8, 8] range

on the Z axis. This is best done by drawing two lines at the beginning and

end of each axis, using the AddLine() method:

mesh.AddLine('x', [-50, 50]) # two lines at -50, 50

mesh.AddLine('y', [-50, 50]) # two lines at -50, 50

mesh.AddLine('z', [-8, 8]) # two lines at -8, 8

Once we have two lines per axis, one can ask CSXCAD to automatically insert

additional lines by interpolating between existing lines, smoothing the final

mesh. This feature provided by the function

SmoothMeshLines(). Its second argument

is the minimum spacing between the lines, here we set it to res. This is the

desired mesh resolution we’ve just calculated:

mesh.SmoothMeshLines('x', res)

mesh.SmoothMeshLines('y', res)

mesh.SmoothMeshLines('z', res)

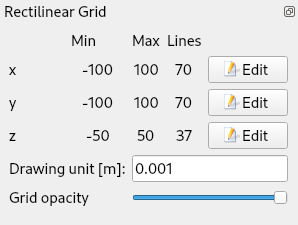

Now is a good time to rerun the script and inspect the 3D model again in AppCSXCAD.

Hint

You may be unable to see the mesh lines in AppCSXCAD, as they may be blocked by the object due to their overlaps. If it happens, it’s necessary to view the model from an angle or a different direction (e.g. if there are no mesh lines when viewed from the top, try dragging the model to view it from an oblique angle). It’s also useful to change the “Grid opacity” slider to the maximum (but it still requires viewing from an angle).

AppCSXCAD only renders 2D and 3D cells, if only one axis has mesh lines, no lines will be displayed.

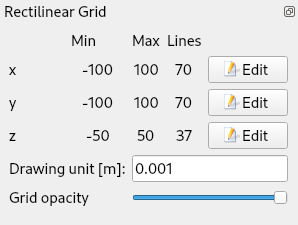

Our 3D model’s XY and YZ cross-sections are:

A Practical Mesh

Unfortunately, using the mesh as previously defined in a simulation will produce incorrect results due to several problems.

Simulation Box Size

Our simulation box exactly fits the waveguide; there’s no empty space around the waveguide in the simulation box, so the electric field around the waveguide is truncated in the model. To be fair, there are legitimate use cases if the surrounding field is irrelevant, such as when modeling an infinite-length waveguide, or a capacitor stuck in a metal box. But here, we are modeling a finite waveguide with realistic behaviors, including fringe fields and radiation.

As a quick fix to the problem, one can make the simulation box several times as big in volume in comparison to the waveguide, giving plenty of room for the simulation to breathe. This allows fringe fields to naturally decay.

We delete the original three

AddLine() calls and replace them with

the following code:

# delete these lines

# mesh.AddLine('x', [-50, 50]) # two lines at -50, 50

# mesh.AddLine('y', [-50, 50]) # two lines at -50, 50

# mesh.AddLine('z', [-8, 8]) # two lines at -8, 8

# mesh.SmoothMeshLines('x', res)

# mesh.SmoothMeshLines('y', res)

# mesh.SmoothMeshLines('z', res)

mesh.AddLine('x', [-100, 100]) # two lines at -100, 100

mesh.AddLine('y', [-100, 100]) # two lines at -100, 100

mesh.AddLine('z', [-50, 50]) # two lines at -50, 50

Important

If it’s necessary to capture fringe fields, increase the size of the simulation box beyond the object. The first and line mesh lines on each axis define the simulation box’s boundary.

Zero-Thickness Metal Alignment

The Z mesh lines are now going from -50 to 50, and we’re going to

rely on automatic interpolation

(by SmoothMeshLines())

to fill the gaps with additional lines.

The lack of guaranteed mesh line alignment becomes a problem.

Zero-thickness objects like the metal plates must align to an exact mesh

line, otherwise these objects can’t be simulated and will be ignored

by the simulator. Thus, we create two mesh lines on the Z axis at the

exact level of the plates:

# zero-thickness metal plates need mesh lines at their exact levels

mesh.AddLine('z', [-8, 8])

Important

Zero-thickness metal plates (and other planar objects) need mesh lines at their exact levels.

1/3-2/3 Rule

After solving the misalignment on the Z axis, ironically, we have an opposite problem on the XY plane. On both planes, the mesh is perfectly aligned with the edges of the waveguide plates, which introduces numerical inaccuracies.

In FDTD, a fundamental error source is the singularities around metal edges, which have strong electric fields that are difficult to calculate properly. As long as the mesh line and metal edge are aligned exactly, the simulation accuracy is degraded unnecessarily - increasing the mesh resolution is inefficient and ineffective. It’s wasteful and only has a marginal effect.

To mitigate this technical limitation, the mesh should be intentionally misaligned with metal edges. For the best results, we introduce additional cells with different sizes around the edge, creating a non-uniform rectilinear mesh with variable spacing. Around the metal edge, the metal occupies 1/3 of a cell, while the vacuum or insulator occupies 2/3 of a cell. This is known as the 1/3-2/3 rule.

Let’s apply the rule to the X and Y axis:

# use a smaller cell size around metal edge, not just the base mesh size

highres = res / 1.5

# strategically draw lines misaligned with the waveguide's left and right edges,

# so that the edge occupies 33% space within a cell.

mesh.AddLine('x', [

# apply 1/3-2/3 rule on the X axis

-50 + highres * 1/3, -50 - highres * 2/3, # left edge

50 - highres * 1/3, 50 + highres * 2/3 # right edge

])

mesh.AddLine('y', [

# apply 1/3-2/3 rule on the Y axis

-50 + highres * 1/3, -50 - highres * 2/3, # lower edge

50 - highres * 1/3, 50 + highres * 2/3 # upper edge

])

The interval between the 1/3 and 2/3 mesh lines (i.e. the length of the

cell) is highres, which is smaller than the base interval res by a

factor of 1.5. This is a workaround: If the same mesh resolution is

used for all cells, when we later smooth the mesh,

SmoothMeshLines() may add additional mesh

lines within our handcrafted cells, effectively undoing the 1/3-2/3 rule.

Using the highres interval works around the problem, since

SmoothMeshLines() is not allowed to

subdivide an interval smaller than res. A factor of 1.5 is recommended to

preserve mesh smoothness.

Finally we resmooth the mesh:

mesh.SmoothMeshLines('x', res)

mesh.SmoothMeshLines('y', res)

mesh.SmoothMeshLines('z', res)

Now let’s inspect the model again; it’s now much better.

Hint

Perspective. The mesh line alignment may look misleading in AppCSXCAD due to an oblique camera angle in the 3D scene. Click the 2D button for a planar view.

When in doubt, use Rectilinear Grid panel’s Edit button

(or call GetLines()) to check mesh

coordinates manually.

Mesh interval. Use a smaller mesh interval highres = res / 1.5

for cells where 1/3-2/3 rules is applied

to prevent SmoothMeshLines()

from undoing it. Alternatively, one may avoid calling this function by:

Adding mesh lines one by one manually.

Extracting all generated lines and removing unwanted ones.

Moving the whole simulated structure by an offset.

For our purpose, the highres workaround is the most convenient solution.

Imperfect rule is still better than no rule. If the simulated structure is complicated, making it difficult to apply the 1/3-2/3 rule, at least try avoiding an exact alignment between metal edge and the mesh. This won’t be as accurate as the 1/3-2/3 rule, but still gives a small accuracy boost at no cost.

Optional: Create A Field Dump Box

Some applications make use of the raw electromagnetic fields, not just the input and output signals. We can do this by creating a “dump box” (a region in space where field values are recorded) to save field samples to disk. For troubleshooting malfunctioning setups, this is especially helpful as one can identify the problematic region through direct visualization.

Several kinds of dump boxes exist.

Time-domain dumps of electric field \(\mathbf{E}\), auxiliary magnetic field \(\mathbf{H}\), electric conduction current \(\mathbf{J}\), total current density \(\mathrm{\nabla} \times \mathbf{H}\), electric displacement field \(\mathbf{D}\), and magnetic field (flux density) \(\mathbf{B}\), with their

dump_typenumbered from0to5.Frequency-domain dumps of electric field, auxiliary magnetic field, electric conduction current, total current density, electric displacement field, and magnetic field (flux density), numbered from

10to15.Specific Absorption Rate (SAR) for biological EM radiation exposure analysis.

Near-Field to Far-Field Transformation (NF2FF) for antenna analysis (special setup required, via

openEMS.openEMS.CreateNF2FFBox()and a separate post-processing tool).

See also

For usage, see CSXCAD.ContinuousStructure.AddDump(). For a detailed

list of parameters, see CSXCAD.CSProperties.CSPropDumpBox.

In this example, we will dump the total current density (dump_type=3)

on the upper waveguide plate as a 2D surface, using the

AddDump() function:

dump = csx.AddDump("curl_H_upper", dump_type=3)

dump.AddBox(start=[-100, -100, 8], stop=[100, 100, 8])

We do something slightly unusual here: The XY slice of the entire simulation box is dumped at Z = 8, not just the waveguide plate. This way, we can visualize the current both on the waveguide plates and in vacuum, allowing us to see radiated field in the surrounding free space.

Note

openEMS calculates the total current density via Ampere-Maxwell’s law \(\mathrm{\nabla} \times \mathbf{H}\), which is \(\mathbf{J} + \frac{\partial \mathbf{D}}{\partial t}\) (i.e. the sum of conduction current and displacement current).

Purpose of Ports

The bulk of the 3D modeling work is nearly complete. The final step is introducing a port and its excitation signal.

Ports are best understood as the virtual 3D counterpart of physical ports on RF/microwave components, such as the standard 50 Ω input or output ports on circuit boards, signal generators, oscilloscopes, and especially Vector Network Analyzers (VNA). A port is treated as a lumped circuit, located at a defined position. It acts as a voltage source or load with a resistive impedance. It can inject a signal to the Device-Under-Test (DUT) or measure the DUT’s response, either from its own signal or from another port.

The “port” in openEMS serves a purpose similar to the physical

ports on Vector Network Analyzers and circuit boards. Both kinds of

ports are used to inject an input signal at a particular point in the

Device-Under-Test (DUT), and to measure what comes out at another point.

The DUT is thus characterized as a black box, solely represented using

its input-output relationships without an internal structure.

Note that port implementations are fundamentally different in

physical instruments (via circuits) and in openEMS simulations

(by loading numerical values into Yee cells). Image by Julien Hillairet,

from the scikit-rf project, licensed under BSD-3, modified for clarity.

Internally, a port is implemented by locating the Yee cells occupied by the port, and setting the numerical values of the electric fields in these cells based on the excitation waveform. Thus, a port can be understood as a source that injects electromagnetic energy into the simulation, helping establish initial conditions for the system. Simultaneously, a lumped resistor and a probe are also created at the same location as the port, allowing it to provide a matched load for the signal, or to measure the voltage or current at this region.

Select the Right Port Type

In openEMS, ports are ideal sources of EM fields, but they are not ideal launchers of EM waves into structures due to a discontinuity at the boundary between the port and the structure. If port placement is not optimized, this region of discontinuity may introduce artifacts such as reflections or excitation of spurious modes. Optimizing the placement and implementation of a port reduces these artifacts. This can be done by using smooth transitions or by shaping the electric fields initially injected by the port.

In openEMS, the standard port is the lumped port

(AddLumpedPort()) that works with most structures.

If an optimal transition is needed, openEMS also provides optimized implementations

of curved (AddCurvePort.m), microstrip (MSLPort()),

stripline (AddStripLinePort.m), coplanar waveguide (AddCPWPort.m),

and coax cable (AddCoaxialPort.m) ports. For now, the lumped ports

suffice for our purpose.

Note

Some port types are not ported (no pun intended) to Python yet.

Most specialized ports in openEMS are signal integrity optimizations rather

than strict requirements. However, in some cases, specialized ports are required

to excite the structure properly. In a rectangular or circular waveguide,

there is only one conductor. An ordinary port can’t excite it correctly,

as the waveguide is essentially a DC short circuit (unlike our parallel-plate

waveguide, which has two conductors). Enclosed waveguides require

special waveguide ports to excite the unique TE-mode waves. This is why

openEMS provides general waveguides (WaveguidePort()),

rectangular waveguides (RectWGPort()), and circular

waveguides (AddCircWaveGuidePort.m) ports.

Note

Like physical ports on real devices, the virtual ports in openEMS are not perfect. They’re ideal sources of EM fields, but they are not ideal launchers of EM waves into structures. A port creates a region of discontinuity, so they may introduce artifacts. Optimizing the placement and implementation of a port reduces artifacts. Alternatively, these artifacts can be removed through calibration or de-embedding algorithms, an advanced topic beyond the scope of this tutorial.

The artifacts introduced by a two-port measurement can be viewed as two linear circuits (left error box, right error box) cascaded in series with the DUT. All three circuits are represented as three matrices, called their S-parameters. Measurement error can be reduced by making error boxes nearly transparent using optimized port transitions. Alternatively, by mathematically removing the port’s contributions from the measured response using linear algebra, a process known as calibration or de-embedding (image by Ziad Hatab et, al., licensed under CC BY-SA 4.0 14)

Test Fixture as 1-Port or 2-Port Network

To analyze the frequency response of the DUT, both 1-port, 2-port, and

multi-port measurements are available. In a 1-port measurement (shunt

method), a signal is injected into the DUT using a 50 Ω port, and the

reflected signal at the same port is measured. In a 2-port measurement,

the DUT is connected either in series (series method) or parallel

(shunt-through method) between the transmitter and receiver.

A signal is injected into the DUT using a 50 Ω transmitter port, and the

received signal is measured by the 50 Ω receiver port at the other side.

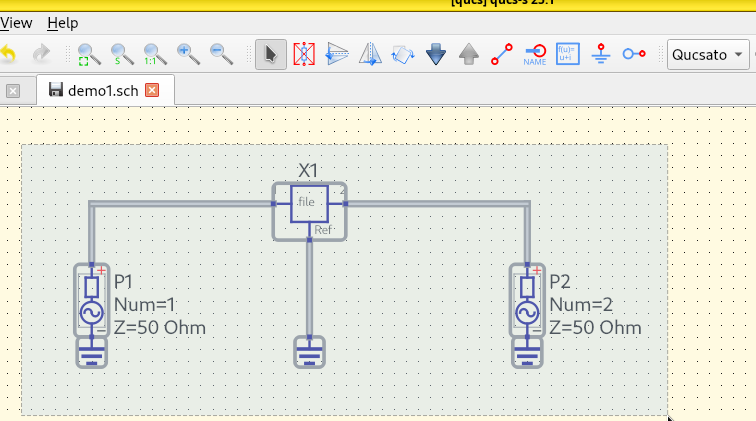

The 2-port techniques are shown in the following circuit diagram (the

impedance Z is a function of frequency).

2-port shunt-through measurement (DUT in parallel), and 2-port series (DUT in series) measurement.

In the real world, the 1-port measurement method is only accurate when the DUT’s impedance is close to the port impedance. If the impedance of the DUT is too high or too low, almost all energy is reflected back. overwhelming the receiver with strong reflections, making them are hard to distinguish. For low-impedance DUTs, results are also sensitive to the port’s contact resistance. Both result in significant measurement errors.

Instead, two-port measurements detect the weak signal transmitted across the DUT (“filtered” by a large series impedance or a low parallel impedance), taking advantage of the sensitive radio receiver in the VNA. This allows us to determine the DUT’s impedance.

To illustrate the general principle of two-port networks and S-parameters in microwave measurements, we follow the 2-port method here.

Create Ports

Ports and excitations are associated with the FDTD simulation object

openEMS(). We need to create an instance of the

simulation, and link the CSXCAD 3D structure csx with the

simulator:

import openEMS

fdtd = openEMS.openEMS()

fdtd.SetCSX(csx)

To use a lumped port, call the openEMS object’s

AddLumpedPort() method.

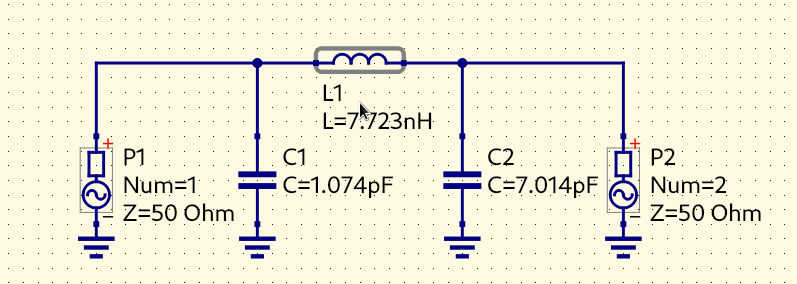

Let’s create two ports at the leftmost and rightmost sides of the waveguide. Port 1 should be centered at x = -50, y = 0, and Port 2 should be centered at x = 50, y = 0. Lumped ports should touch both waveguide plates, as the port is connected across them, so their Z coordinates span from [-8, 8]. This matches the intuition of a circuit diagram, in which a lumped port is vertically connected across the horizontal transmission line. The port’s internal voltage source acts as both a wire and a source of electric field.

An ideal lumped port is connected vertically across a horizontal circuit. Its internal voltage source acting as both a wire and a source of electric field. A lumped excitation port in openEMS works similarly here.

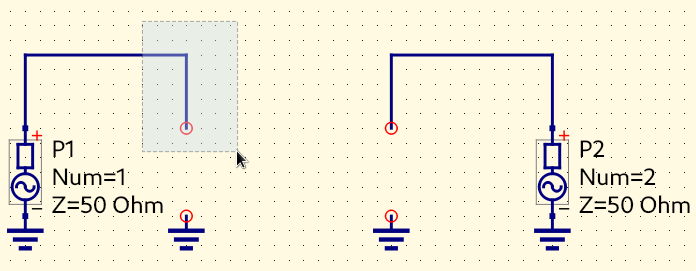

To complicate the issue further, a port must cross at least a mesh line, since excitation is implemented by setting the electric field at the corresponding Yee cells. Since we have enforced the 1/3-2/3 rule, if the port is placed exactly at the edge of the plate, no mesh lines pass through the port. Thus, as a compromise, we shift the port’s location to the nearest mesh lines instead. This may introduce a small error due to a measurement plane. But these issues are negligible for this demo.

Important

A port must cross or align exactly with at least one mesh line, otherwise it can’t be simulated.

Another consideration is whether the port should have a length and width. For transmission line simulations, the port should have a width as wide as the line to minimize discontinuity. On the other hand, one can usually keep the length 0, it represents a measurement plane which doesn’t extend into the line. Here to make the problem more interesting, we simulate a port much smaller than the width of the plates to study the consequences of impedance mismatch. We choose to create a port with a 5 mm width.

Both ports have an internal impedance of 50 Ω, but only the first port

is used for excitation, so we set Port 1’s excite attribute to 1 (input),

and Port 2’s excite attribute to 0 (load and output). The parameter z

is the direction of the field, pointing from one plate to another on the Z

axis.

Both ports are also added to a Python list to keep track of them for future processing:

z0 = 50

port = [None, None]

port[0] = fdtd.AddLumpedPort(1, z0, [-50 + 1/3 * highres, -2.5, -8], [-50 + 1/3 * highres, 2.5, 8], 'z', excite=1)

port[1] = fdtd.AddLumpedPort(2, z0, [ 50 - 1/3 * highres, -2.5, -8], [ 50 - 1/3 * highres, 2.5, 8], 'z', excite=0)

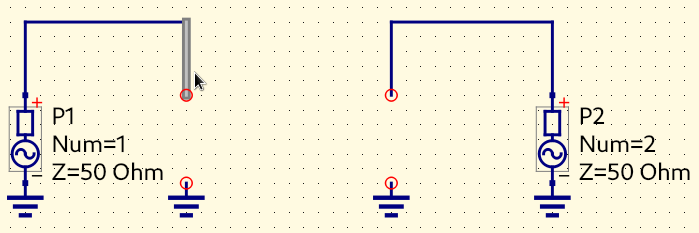

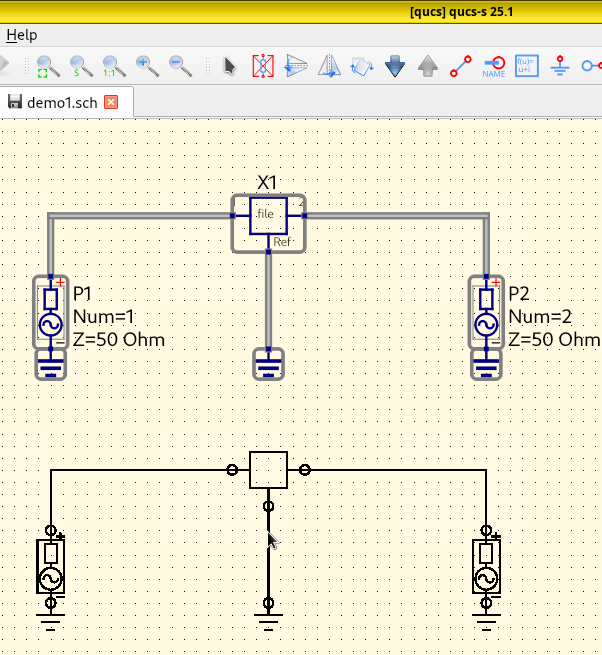

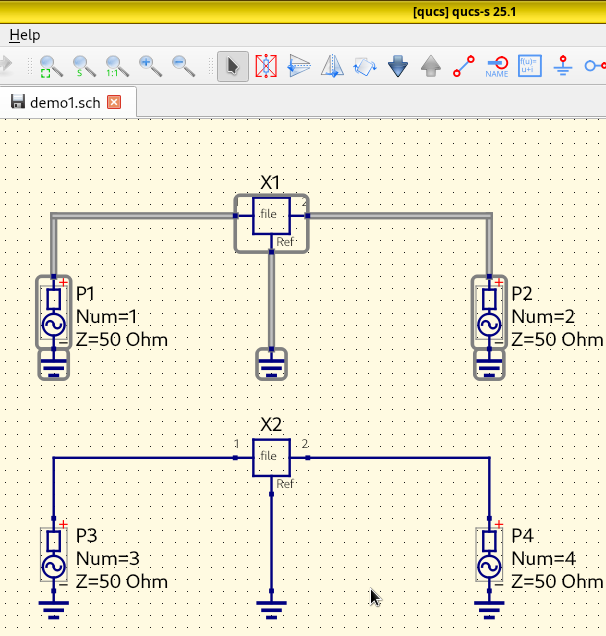

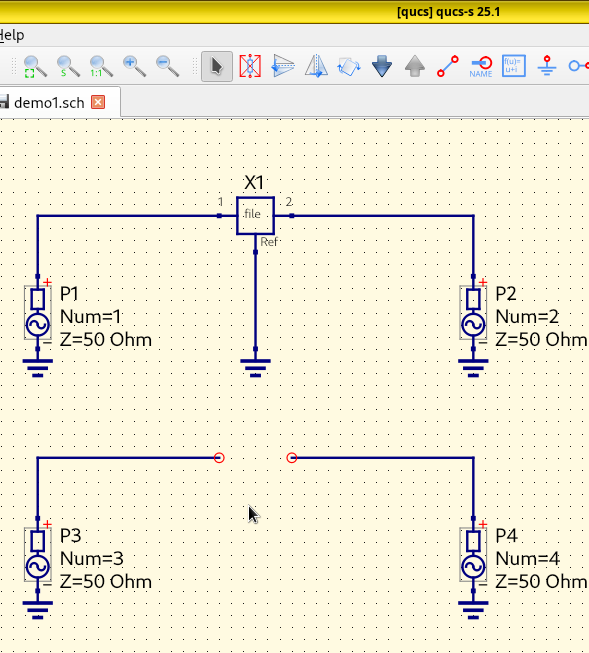

The following images show the ports we just created.

Create Excitation

We need to assign an input signal to the excitation port.

In FDTD simulations, a Gaussian pulse is normally used as it provides a wideband and smooth signal without discontinuous jumps. In openEMS, the Gaussian pulse is implemented as a sinusoidal carrier at the center frequency, with its amplitude modulated by a Gaussian function. This signal produces a well-distributed spectrum with a wide range of frequencies in both sidebands around the carrier. This relatively clean spectrum enables openEMS to accurately extract the DUT’s frequency response in the frequency domain.

Once the DUT’s frequency response is known, linear circuit analysis tools can evaluate its behavior under other input signals, so there’s no loss of generality.

Note

In contrast, pulses such as the Dirac impulse

(SetDiracExcite()) or the Heaviside step

function (SetStepExcite()) have discontinuous

jumps, reaching the full value in just a single timestep. This can

cause problems like the unrealistic excitation of rarely-seen high-order

modes in transmission lines, or the overshoot and ringing of its rising

edge due to numerical dispersion.

As a workaround, users can provide custom

bandwidth-limited expressions to openEMS (no built-in implementations

exist currently) via SetCustomExcite(). For an

example, see 7. However, these pulses also suffer from rapid energy

roll-off at high frequencies. The Gaussian pulse, by comparison,

retains significant energy in both sidebands around the center carrier

frequency.

To apply a Gaussian excitation, we call the

SetGaussExcite() method of the openEMS object.

The first argument is its center frequency,

the second argument is its -20 dB bandwidth, defining the signal’s

spectral “spread”. For a wideband simulation, both arguments should

be set to 1/2 of the simulation’s upper frequency target:

# Centered around 5 GHz with a 5 GHz 20 dB bandwidth.

# Lower sideband covers 0 - 5 GHz, upper sideband covers 5 - 10 GHz.

fdtd.SetGaussExcite(f_max / 2, f_max / 2)

Specify the Boundary Conditions

In openEMS, all physical phenomena occur in a small simulation box, so

we must decide what happens to the electromagnetic fields at its edges.

These are known as the boundary conditions of Partial Differential

Equations (PDEs). To create an effective simulation, we must select the

appropriate boundary conditions. There are six in total, located at

the six faces of the box: x_min, x_max, y_min, y_max,

z_min, z_max. Each is independently adjustable.

Reflecting (Dirichlet) Boundary Conditions

If the finite nature of the simulation box and the reflection of EM waves at the boundaries are acceptable, reflecting boundary conditions offer a simple zero-overhead solution. They efficiently model structures inside metal enclosures, above a ground plane, or with an electric or magnetic field symmetry across a plane. No explicit modeling is necessary; the boundary conditions implicitly enforce these behaviors.

A simulation box with PEC at all boundaries acts like a shielded enclosure. EMC test labs use room-sized metal enclosures to create reverberation chambers. Taking advantage of the standing waves due to reflections, one can create strong electric fields at localized regions to generate electromagnetic interference for testing. Image by Dr. Hans Georg Krauthäuser (Hgk at English Wikipedia), licensed under CC BY-SA 3.0.

Perfect Electric Conductor (PEC): The simplest treatment sets the (tangential) electric field at the boundary to 0. Since the electric field lines can’t penetrate this boundary, it’s equivalent to a Perfect Electric Conductor (PEC) with infinite conductivity, also known as an Electric Wall. All incoming waves are fully reflected back, analogous to a 1D transmission line terminated by a short circuit.

Perfect Magnetic Conductor (PMC): By duality, it sets the magnetic field to 0 at the boundary. It acts as a boundary at which the magnetic field lines can’t penetrate. It’s equivalent to a Perfect Magnetic Conductor (PMC) with infinite permeability, also known as the Magnetic Wall. All incoming waves are fully reflected back as well, but with a phase opposite to that of the PEC, analogous to a 1D transmission line terminated by an open circuit. It’s used mainly as a mathematical tool to enforce field symmetry when simulating a half-structure, as no natural material in the real world behaves like a PMC.

Mathematically, both PEC and PMC are Dirichlet boundary conditions that enforce fixed field values (e.g. zero).

Note

For our simulation, instead of explicitly modeling metal

plates, we can model a vacuum with nothing inside, taking advantage

of the PEC boundary conditions at z_min and z_max for

fast computation. However, this is out of this tutorial’s scope,

and it won’t capture the fringe fields above and below. We won’t use

PEC or PMC in this example.

Absorbing Boundary Conditions (ABC)

In open-boundary problems, such as antennas or structures with radiation loss, Absorbing Boundary Conditions (ABC) must be used to suppress reflections to prevent spurious simulation results. At its boundaries, the electromagnetic waves are absorbed and dissipated without reflecting back, creating the illusion of an infinitely large free space. If PEC and PMC are analogous to a shorted or opened transmission line, the ABC is analogous to a termination resistor.

In general, these simulations should use a simulation box larger than the structure to avoid intrusion of strong fringe fields at the boundary. However, deliberately running a transmission line into the PML (defined below) can be used as a perfect termination. This allows one to terminate a transmission line without knowing its characteristic impedance, enabling impedance measurement. In fact, openEMS’s microstrip ports don’t create a lumped termination resistor by default, expecting users to place them into the PML at boundaries.

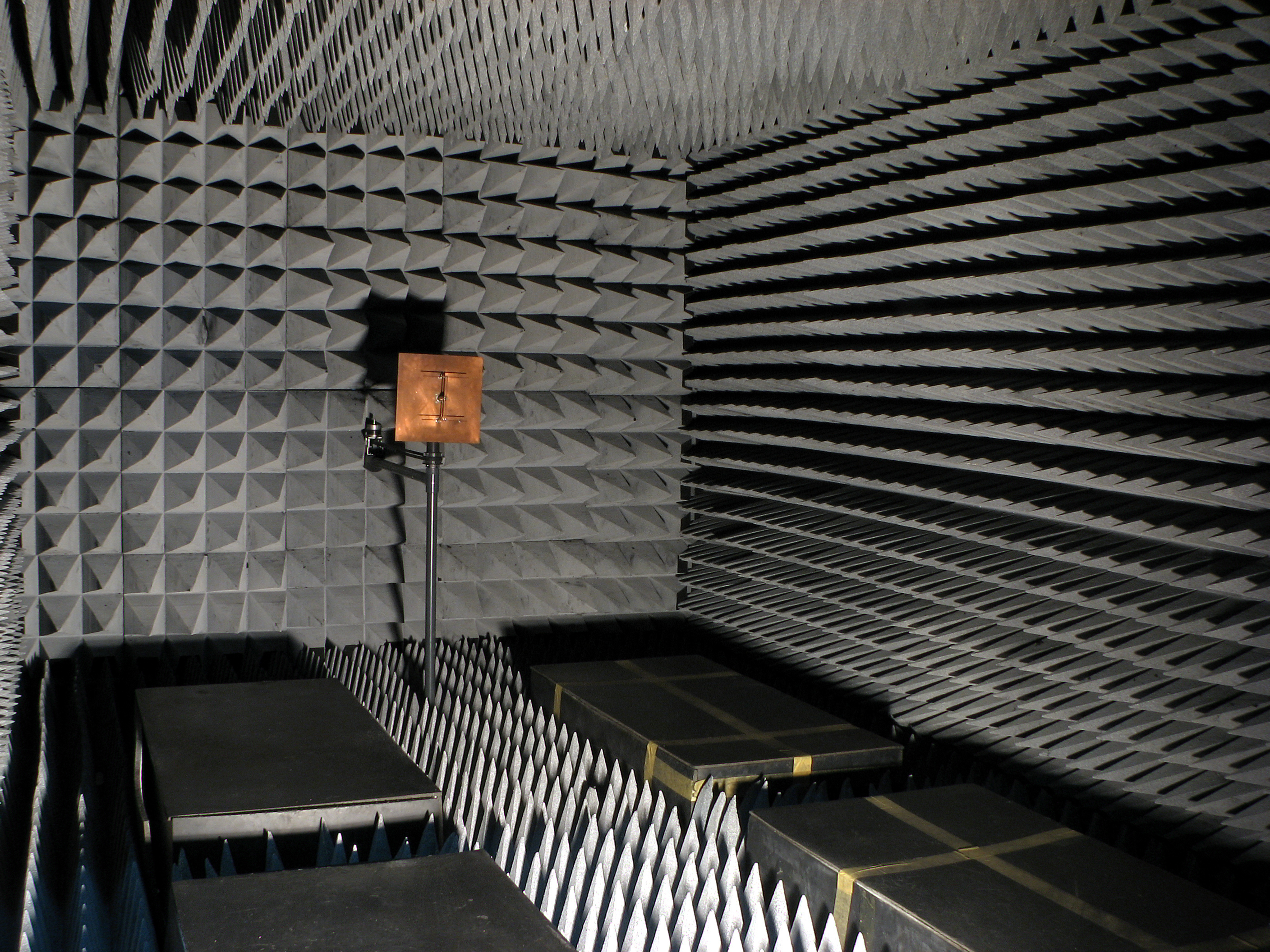

A simulation box with PML at all boundaries acts like an anechoic chamber in an EMC test lab, mimicking an infinitely large free space. Image by Adamantios (at English Wikipedia), licensed under CC BY-SA 3.0.

Two kinds of Absorbing Boundary Conditions are implemented in openEMS.

Mur’s Boundary Condition (MUR). This is a first-generation boundary condition purely defined by differential equations, originally invented by Gerrit Mur in the 1980s. It has a moderate computational overhead, but it works only if the EM wave is traveling at a direction orthogonal to the boundary, with a well-defined phase velocity (e.g. the speed of light). Thus, reflections may cause errors if strong radiation exists due to imperfect absorption.

Perfectly Matched Layer (PML). This is the second-generation boundary condition proposed in the 1990s, modeling the behavior of a hypothetical EM wave-absorbing material. Unlike Mur’s ABC, PML occupies some physical cells in the simulation box (the actual boundary at the true edge remains PEC). This mimics the wave-absorbing foam on the wall of an anechoic chamber in EMC test labs.

PML is a more effective absorber and is easy to use, but it has the highest computational overhead (especially in openEMS, due to suboptimal implementation). Avoid it if efficiency is critical (e.g. only use PML at the simulation box’s face directly hit by radiation, and use MUR for other boundaries). Intrusion of fringe fields and evanescent waves into the PML can destabilize it, causing the simulation to “blow-up”. Radiating structures must be kept at a distance of \(\lambda / 4\).

Important

In openEMS, PML_8 is commonly used, meaning the nearest 8 mesh lines

of the simulation box are dedicated to the PML. This is an assumption made

by the simulator and not visible in AppCSXCAD. Ensure your structures do not

overlap with edge cells (unless intentionally terminating a region with

the PML). Radiating structures must be kept at a distance of \(\lambda / 4\)

from PML as intrusion of evanescent waves (fringe fields) can create

numerical instability.

Set Boundary Conditions

To set the boundary conditions of the simulator, use

openEMS.openEMS.SetBoundaryCond() of the openEMS class. Its syntax is:

SetBoundaryCond(bc) where bc is a list with 6 elements with the order

of [x_min, x_max, y_min, y_max, z_min, z_max]. Each element is a string or

integer according to the following table. Note that the use of integers is

discouraged due to poor readability, but one may encounter them in older examples.

Boundary Condition |

String |

ID |

Notes |

|---|---|---|---|

Perfect Electric Conductor |

|

0 |

Reflective. Fast. |

Perfect Magnetic Conductor |

|

1 |

Reflective. Fast. |

Mur’s Absorbing Boundary |

|

2 |

Absorbing. Slow. Only absorbs waves orthogonal to the boundary. Named after Gerrit Mur. |

Perfectly Matched Layer |

|

3 |

Absorbing. Slowest.

Occupies Keep structures For radiating structures, λ / 4 away. |

PML_8 is the boundary condition that we’re going to use, so we write:

fdtd.SetBoundaryCond(["PML_8", "PML_8", "PML_8", "PML_8", "PML_8", "PML_8"])

Start Simulation

Finally, to start the simulation, run:

fdtd.Run(simdir)

Code Checkpoint 1

Our Existing Code So Far

As a checkpoint of our progress, the following is the complete code one obtains if the previous instructions are followed. Note that in this code snippet, we rearranged the order of some lines according to Python’s coding convention of import first, constant definitions second, and main logic the last:

import sys

import math

import pathlib

import CSXCAD

import openEMS

from openEMS.physical_constants import C0

# calculate mesh resolution according to simulation frequency

unit = 1e-3

f_min = 100e6 # post-processing only, not used in simulation

f_max = 10e9 # determines mesh size and excitation signal bandwidth

epsilon_r = 1

v = C0 / math.sqrt(epsilon_r)

wavelength = v / f_max / unit # convert to millimeters

res = wavelength / 10

# use a smaller cell size around metal edge, not just the base mesh size

highres = res / 1.5

# port impedance

z0 = 50

# determine the simulation output path

# find the directory of the script itself

filepath = pathlib.Path(__file__)

# create a directory named after the script, but without ".py"

simdir = filepath.with_suffix("")

simdir.mkdir(parents=True, exist_ok=True)

# find the filename of the script itself, and replace ".py" with ".xml"

xmlname = filepath.with_suffix(".xml").name

# concat two paths

xmlpath = simdir / xmlname

csx = CSXCAD.ContinuousStructure()

fdtd = openEMS.openEMS()

# associate the CSXCAD structure with the FDTD simulator

fdtd.SetCSX(csx)

# set unit of measurement in the CSXCAD drawing

mesh = csx.GetGrid()

mesh.SetDeltaUnit(unit)

# Create an instance of material named "plate".

# AddMetal() creates a Perfect Electric Conductor.

metal = csx.AddMetal('plate')

# Build two 3D shapes from -50 to 50 on the X/Y axes, located at Z = -8

# and Z = 8 respectively. Note that the starting and stopping Z coordinates

# of each plate are the same, so these metal plates have zero thickness.

metal.AddBox(start=[-50, -50, -8], stop=[50, 50, -8]) # lower plate

metal.AddBox(start=[-50, -50, 8], stop=[50, 50, 8]) # upper plate

mesh.AddLine('x', [-100, 100]) # two lines at -100, 100

mesh.AddLine('y', [-100, 100]) # two lines at -100, 100

mesh.AddLine('z', [-50, 50]) # two lines at -50, 50

# zero-thickness metal plates need mesh lines at their exact levels

mesh.AddLine('z', [-8, 8]) # two lines at -8, 8

# strategically draw lines misaligned with the waveguide's left and right edges,

# so that the edge occupies 33% space within a cell.

mesh.AddLine('x', [

# apply 1/3-2/3 rule on the X axis

-50 + highres * 1/3, -50 - highres * 2/3, # left edge

50 - highres * 1/3, 50 + highres * 2/3 # right edge

])

mesh.AddLine('y', [

# apply 1/3-2/3 rule on the Y axis

-50 + highres * 1/3, -50 - highres * 2/3, # lower edge

50 - highres * 1/3, 50 + highres * 2/3 # upper edge

])

mesh.SmoothMeshLines('x', res)

mesh.SmoothMeshLines('y', res)

mesh.SmoothMeshLines('z', res)

dump = csx.AddDump("curl_H_upper", dump_type=3)

dump.AddBox(start=[-100, -100, 8], stop=[100, 100, 8])

port = [None, None]

port[0] = fdtd.AddLumpedPort(1, z0, [-50 + 1/3 * highres, -2.5, -8], [-50 + 1/3 * highres, 2.5, 8], 'z', excite=1)

port[1] = fdtd.AddLumpedPort(2, z0, [ 50 - 1/3 * highres, -2.5, -8], [ 50 - 1/3 * highres, 2.5, 8], 'z', excite=0)

# save structure to file for inspection

csx.Write2XML(str(xmlpath))

# Centered around 5 GHz with a 5 GHz 20 dB bandwidth.

# Lower sideband covers 0 - 5 GHz, upper sideband cover 5 - 10 GHz.

fdtd.SetGaussExcite(f_max / 2, f_max / 2)

fdtd.SetBoundaryCond(["PML_8", "PML_8", "PML_8", "PML_8", "PML_8", "PML_8"])

fdtd.Run(simdir)

Code Refactoring

The program above is not entirely satisfactory. If we want make some small adjustments to the model, it forces us to run the simulation. For improved modularity, the 3D modeling, ports creation, simulation, and post-processing should each be written in separated functions, so each part can be ran and reran separately. This is important for repeated simulations with different parameters, which are encountered in all but the most trivial simulations.

The following refactored program provides a reasonable skeleton to build upon further:

import sys

import math

import pathlib

import CSXCAD

import openEMS

from openEMS.physical_constants import C0

# calculate mesh resolution according to simulation frequency

unit = 1e-3

f_min = 100e6 # post-processing only, not used in simulation

f_max = 10e9 # determines mesh size and excitation signal bandwidth

epsilon_r = 1

v = C0 / math.sqrt(epsilon_r)

wavelength = v / f_max / unit # convert to millimeters

res = wavelength / 10

# use a smaller cell size around metal edge, not just the base mesh size

highres = res / 1.5

# port impedance

z0 = 50

# determine the simulation output path

# find the directory of the script itself

filepath = pathlib.Path(__file__)

# use a directory named after the script, but without ".py"

simdir = filepath.with_suffix("")

simdir.mkdir(parents=True, exist_ok=True)

# find the filename of the script itself, and replace ".py" with ".xml"

xmlname = filepath.with_suffix(".xml").name

# concat two paths

xmlpath = simdir / xmlname

def generate_structure(csx):

"""

Generate and return the 3D structure used for simulation.

This function should return a CSXCAD instance, but without changing any

simulation parameters.

"""

# set unit of measurement in the CSXCAD drawing

mesh = csx.GetGrid()

mesh.SetDeltaUnit(unit)

# Create an instance of material named "plate".

# AddMetal() creates a Perfect Electric Conductor.

metal = csx.AddMetal('plate')

# Build two 3D shapes from -50 to 50 on the X/Y axes, located at Z = -8

# and Z = 8 respectively. Note that the starting and stopping Z coordinates

# of each plate are the same, so these metal plates have zero thickness.

metal.AddBox(start=[-50, -50, -8], stop=[50, 50, -8]) # lower plate

metal.AddBox(start=[-50, -50, 8], stop=[50, 50, 8]) # upper plate

mesh.AddLine('x', [-100, 100]) # two lines at -100, 100

mesh.AddLine('y', [-100, 100]) # two lines at -100, 100

mesh.AddLine('z', [-50, 50]) # two lines at -50, 50

# zero-thickness metal plates need mesh lines at their exact levels

mesh.AddLine('z', [-8, 8]) # two lines at -8, 8

# strategically draw lines misaligned with the waveguide's left and right edges,

# so that the edge occupies 33% space within a cell.

mesh.AddLine('x', [

# apply 1/3-2/3 rule on the X axis

-50 + highres * 1/3, -50 - highres * 2/3, # left edge

50 - highres * 1/3, 50 + highres * 2/3 # right edge

])

mesh.AddLine('y', [

# apply 1/3-2/3 rule on the Y axis

-50 + highres * 1/3, -50 - highres * 2/3, # lower edge

50 - highres * 1/3, 50 + highres * 2/3 # upper edge

])

mesh.SmoothMeshLines('x', res)

mesh.SmoothMeshLines('y', res)

mesh.SmoothMeshLines('z', res)

dump = csx.AddDump("curl_H_upper", dump_type=3)

dump.AddBox(start=[-100, -100, 8], stop=[100, 100, 8])

return csx

def setup_ports(fdtd, csx):

"""

Create and return ports to inject and measure signals at a particular mesh

location.

This function should only create ports, but without changing the structure

or simulation parameters.

"""

port = [None, None]

port[0] = fdtd.AddLumpedPort(1, z0, [-50 + 1/3 * highres, -2.5, -8], [-50 + 1/3 * highres, 2.5, 8], 'z', excite=1)

port[1] = fdtd.AddLumpedPort(2, z0, [ 50 - 1/3 * highres, -2.5, -8], [ 50 - 1/3 * highres, 2.5, 8], 'z', excite=0)

return port

def simulate(fdtd, csx):

"""

Setup boundary conditions, excitation signals, and finally run the

simulator.

This function should run the simulator from the given "fdtd" and "csx"

instance, without changing them.

"""

# Centered around 5 GHz with a 5 GHz 20 dB bandwidth.

# Lower sideband covers 0 - 5 GHz, upper sideband cover 5 - 10 GHz.

fdtd.SetGaussExcite(f_max / 2, f_max / 2)

fdtd.SetBoundaryCond(["PML_8", "PML_8", "PML_8", "PML_8", "PML_8", "PML_8"])

fdtd.Run(simdir)

def postproc(port):

"""

Process the data generated by a complete simulation. Only knowledge of ports

are necessary. This function is agnostic about the structure and simulator

parameters.

"""

pass

if __name__ == "__main__":

csx = CSXCAD.ContinuousStructure()

fdtd = openEMS.openEMS()

# associate CSXCAD structure with an openEMS simulation

fdtd.SetCSX(csx)

if len(sys.argv) <= 1:

print('No command given, expect "generate", "simulate", "postproc"')

elif sys.argv[1] in ["generate", "simulate"]:

# generate 3D structure

generate_structure(csx)

setup_ports(fdtd, csx)

csx.Write2XML(str(xmlpath))

if sys.argv[1] == "simulate":

# run simulator

simulate(fdtd, csx)

elif sys.argv[1] == "postproc":

# run post-processing only, without running the simulator

port = setup_ports(fdtd, csx)

postproc(port)

else:

print("Unknown command %s" % sys.argv[1])

exit(1)

This program accepts three separate commands: generate, simulate,

and postproc. This allows incremental development.

One can immediately inspect the model in AppCSXCAD without starting the simulation via:

python3 Parallel_Plate_Capacitor_Waveguide.py generate

Once checked, one can manually start the simulation via:

python3 Parallel_Plate_Capacitor_Waveguide.py simulate

Likewise, one can experiment with different post-processing routines based on existing data without wasting time on re-running the simulation via:

python3 Parallel_Plate_Capacitor_Waveguide.py postproc

In the future, it’s also easy to modify the program to add parameterized structure generation, multi-pass simulations, and other features.

Run Simulation

Expected Simulator Output

If everything works as expected, the following screen appears. For this small simulation, it should finish within a few minutes:

$ python3 Parallel_Plate_Capacitor_Waveguide.py

----------------------------------------------------------------------

| openEMS 64bit -- version v0.0.36-16-g7d7688a

| (C) 2010-2023 Thorsten Liebig <thorsten.liebig@gmx.de> GPL license

----------------------------------------------------------------------

Used external libraries:

CSXCAD -- Version: v0.6.3-4-g9257bf1

hdf5 -- Version: 1.12.1

compiled against: HDF5 library version: 1.12.1

tinyxml -- compiled against: 2.6.2

fparser

boost -- compiled against: 1_76

vtk -- Version: 9.1.0

compiled against: 9.1.0

Create FDTD operator (compressed SSE + multi-threading)

FDTD simulation size: 70x70x37 --> 181300 FDTD cells

FDTD timestep is: 5.3429e-12 s; Nyquist rate: 9 timesteps @1.0398e+10 Hz

Excitation signal length is: 108 timesteps (5.77033e-10s)

Max. number of timesteps: 1000000000 ( --> 9.25926e+06 * Excitation signal length)

Create FDTD engine (compressed SSE + multi-threading)

Running FDTD engine... this may take a while... grab a cup of coffee?!?

[@ 4s] Timestep: 1602 || Speed: 72.5 MC/s (2.499e-03 s/TS) || Energy: ~2.70e-19 (-41.66dB)

[@ 8s] Timestep: 3820 || Speed: 100.5 MC/s (1.805e-03 s/TS) || Energy: ~5.35e-20 (-48.70dB)

[@ 12s] Timestep: 6510 || Speed: 121.9 MC/s (1.488e-03 s/TS) || Energy: ~1.86e-20 (-53.30dB)

[@ 16s] Timestep: 9320 || Speed: 127.3 MC/s (1.424e-03 s/TS) || Energy: ~1.09e-20 (-55.59dB)

[@ 20s] Timestep: 12136 || Speed: 127.6 MC/s (1.421e-03 s/TS) || Energy: ~5.33e-21 (-58.72dB)

[@ 24s] Timestep: 14748 || Speed: 118.4 MC/s (1.532e-03 s/TS) || Energy: ~3.62e-21 (-60.39dB)

Multithreaded Engine: Best performance found using 5 threads.

Time for 14748 iterations with 181300.00 cells : 24.01 sec

Speed: 111.35 MCells/s

If there’s a mesh or port alignment alignment problem, openEMS may generate the following warnings. See the linked sections for their respective solution.

Convergence and Divergence (Blow-up)

The simulation runs until the total energy in the simulation box decays to nearly zero, reaching 60 dB below the initial energy injected by the excitation port. When this occurs, the simulation achieves convergence, meaning the transients in the system have dissipated, and the system has reached a steady-state. Thus, the simulation terminates.

Conversely, incorrect or unphysical modeling or meshing may destabilize the simulation, causing blow-ups. The simulation box’s EM field strength diverges over time due to the accumulation of small numerical errors. The total energy may gradually increase unbounded, eventually reaching the floating-point infinity. If the energy shows signs of rapid increases, the simulation should be stopped early via Control-C to avoid wasting time.

Note that the displayed energy value is only a rough, indicative estimate. Factors such as material properties are ignored for simulation speed. For resonating structures (such as cavity resonators and antennas), the energy indicator may fluctuate up and down repeatedly due to the oscillating EM field strengths. The convergence time required for low-loss (high Q) resonators which have minimal energy dissipation, is notoriously long in FDTD simulations. The absence of termination resistances or Absorbing Boundary Conditions makes it difficult to dissipate the injected energy.

Note

The energy decay threshold for termination is adjustable

via SetEndCriteria(), but 60 dB is a

good default. For advanced usage,

SetNumberOfTimeSteps()

and

SetMaxTime() can limit the total

number of timesteps (in iterations) or wall-clock time

(in seconds) to truncate the simulation earlier before

convergence.

Built-In Post-Processing

By now, the electromagnetic field simulation is complete. It’s up to us to analyze and interpret the data.

To analyze the frequency response of the structure, we need to specify a

discrete list of frequencies of interest. One can generate such a list with the

help of numpy’s linspace() function. The following code creates a freq_list

with 1000 evenly-spaced elements from 100 MHz to 10 GHz:

import numpy as np

points = 1000

freq_list = np.linspace(f_min, f_max, points)

Then, call the CalcPort() function on each port object one

by one to calculate its response. This is the reason that we’ve chosen to

append each port object to a list called port, instead of leaving them

as individual variables:

for p in port:

p.CalcPort(simdir, freq_list, ref_impedance=z0)

Port Attribute References

The following port attributes are often necessary in post-processing for frequency response, impedance, and time-domain calculations.

Attribute |

Domain |

Definition |

|---|---|---|

|

Frequency Sample |

Incident Voltage |

|

Frequency Sample |

Reflected Voltage |

|

Frequency Sample |

Total Voltage |

|

Frequency Sample |

Incident Current |

|

Frequency Sample |

Reflected Current |

|

Frequency Sample |

Total Current |

|

Frequency Sample |

Incident Power |

|

Frequency Sample |

Reflected Power |

|

Frequency Sample |

Accepted Power (Incident - Reflected) |

|

Time Sample |

Incident Voltage |

|

Time Sample |

Reflected Voltage |

|

Time Sample |

Total Voltage |

|

Time Sample |

Incident Current |

|

Time Sample |

Reflected Current |

|

Time Sample |

Total Current |

|

Time Sample |

Raw Voltage ( |

|

Time Sample |

Raw Time of Voltage Samples |

|

Time Sample |

Raw Current ( |

|

Time Sample |

Raw Time of Current Samples |

Note for Americans: |

||

Introduction to S-parameters

In radio and high-speed digital electronics engineering, the S-parameters are the universal language to express the characteristics of a linear circuit, allowing one to treat the circuit as a black box with several ports, defined by their input-output relationships.

For a two-port measurement, the circuit is modeled by a 2x2 matrix with 4 complex numbers at each frequency of interest. These parameters can be interpreted as the transmission and reflection of voltage waves in a transmission line.

\[\begin{split}\large{

\begin{bmatrix}

b_1 \\ b_2 \end{bmatrix} =

\begin{bmatrix} S_{11} & S_{12} \\

S_{21} & S_{22} \end{bmatrix}

\begin{bmatrix} a_1 \\ a_2

\end{bmatrix}

}\end{split}\]

|

|

S-parameters can be understood as the transmitted and reflected signals (voltage waves) at the port of a DUT. The DUT itself is seen as a black box, defined only by their input-output relationship Image by Charly Whisky, licensed under CC BY-SA 4.0. |

|

At Port 1, its total voltage can be seen as a superposition of two parts: an incident voltage wave entering Port 1, and a reflected wave leaving from Port 1. Their ratio \(V_\mathrm{ref} / V_\mathrm{inc}\) is the parameter \(S_{11}\). This parameter has several other names: the reflection coefficient \(\Gamma = S_{11}\). When its magnitude is plotted on a log scale, it’s called the return loss \(-10 \cdot \log_{10}(|S_{11}|^2)\).

At Port 2, the voltage or power it receives can also be calculated as a ratio of two quantities: an incident voltage wave entering Port 1, and a transmitted voltage wave leaving from Port 2, called \(S_{21}\). This parameter is also known as transmission coefficient When its magnitude is plotted on the log scale, it’s called the insertion loss \(-10 \cdot \log_{10}(|S_{21}|^2)\). This corresponds to the attenuation of a cable or a filter.

Since a circuit may modify both the amplitude and the phase of a voltage wave, all S-parameters are complex numbers.

Calculate S-parameters

In openEMS, after calling CalcPort() on a port object, its incident and reflected

voltages can be accessed via its uf_inc and uf_ref attributes, which are

numpy lists with the same number of elements as freq_list (which we previously

passed to CalcPort()).

Thus, by definition, one can calculate \(S_{11}\) and \(S_{21}\) as the following:

s11_list = port[0].uf_ref / port[0].uf_inc

s21_list = port[1].uf_ref / port[0].uf_inc

Hint

We utilize numpy’s broadcasting feature here. The quantities uf_ref and

uf_inc are arrays, not scalars. Every element represents a single value at

the a frequency point. But instead of looping over each element explicitly,

we can work on all elements simultaneously:

a = np.array([1, 2, 3])

b = np.array([4, 5, 6])

c = a + b # [5, 7, 9]

d = c * 2 # [10, 14, 18]

This way, we can do element-wise arithmetic automatically on the whole

numpy arrays. We will use this feature extensively throughout the

rest of this tutorial.

Two S-parameters \(S_{12}\) and \(S_{22}\) are still missing here. The correct way of doing so is restarting the simulation, but with port 2 as the excitation port instead of port 1. This means that in the general case, we must refactor our code to move the port creation and simulation logic into separate functions.

But here, since our parallel-plate waveguide is symmetric and reciprocal, it doesn’t matter if we excite the left side and terminate the right side, or vice versa, so we can assume \(S_{12} = S_{21}\) and \(S_{11} = S_{22}\):

# hack: assume symmetry and reciprocity

# This only correct for passive linear reciprocal circuit!

s22_list = s11_list

s12_list = s21_list

Plot S-parameters via matplotlib

After going through the long exercise, it’s now a good time to take a quick look at the S-parameters we’ve obtained, using matplotlib:

from matplotlib import pyplot as plt

Here, we’re interested in two types of graphs that all RF/microwave engineers care about (Smith charts and more sophisticated analysis will be introduced later, using third-party software).

The scalar return loss (magnitude of \(S_{11}\) in decibels) on a line chart shows how much power is reflected by the DUT back to the input port at each frequency. A high loss like 20 dB implies no reflection, indicating a good impedance match or a resonance frequency:

s11_db_list = -10 * np.log10(np.abs(s11_list) ** 2)

plt.figure()

plt.plot(freq_list / 1e9, s11_db_list, label='$S_{11}$ dB')

plt.grid()

plt.legend()

plt.xlabel('Frequency (GHz)')

plt.ylabel('Return Loss (dB)')

# By convention, return loss values increase downward on the Y axis.

# This is consistent with the plot shapes on spectrum analyzers, and

# perhaps explains why the customary "wrong" sign convention is used.

plt.gca().invert_yaxis()

plt.show()

Since \(S_{11}\) is a vector (complex number), we can also plot its phase angle for completeness. But note that the phase is difficult to interpret, so the Smith chart (covered later) is a better tool for this job:

s11_deg_list = np.angle(s11_list, deg=True)

plt.figure()

plt.plot(freq_list / 1e9, s11_deg_list, label='$S_{11}$ deg')

plt.grid()

plt.legend()

plt.xlabel('Frequency (GHz)')

plt.ylabel('S11 Phase (deg)')

plt.show()

As we can see from the plot, there’s a sharp 40 dB notch at 500 MHz, indicating almost all power is delivered into the load with almost no reflection. This is usually the sign that the DUT is resonating. Above 2 GHz, the reflection becomes extremely strong, as the return loss is only between 0 dB to 6 dB, suggesting a serious physical discontinuity or electrical impedance mismatch.

The scalar insertion loss (magnitude of \(S_{21}\) in decibels) on a line chart shows how much power is transmitted into the second port, which shows the attenuation of signals at each frequency:

s21_db_list = -10 * np.log10(np.abs(s21_list) ** 2)

plt.figure()

plt.plot(freq_list / 1e9, s21_db_list, label='$S_{21}$ dB')

plt.grid()

plt.legend()

plt.xlabel('Frequency (GHz)')

plt.ylabel('Insertion Loss (dB)')

# By convention, insertion loss values increase downward on the Y axis.

# This is consistent with the plot shapes on spectrum analyzers, and

# perhaps explains why the customary "wrong" sign convention is used.

plt.gca().invert_yaxis()

plt.show()

s21_deg_list = np.angle(s21_list, deg=True)

plt.figure()

plt.plot(freq_list / 1e9, s21_deg_list, label='$S_{21}$ deg')

plt.grid()

plt.legend()

plt.xlabel('Frequency (GHz)')

plt.ylabel('S21 Phase (deg)')

plt.show()

From the simulation data, we can see that this parallel-plate waveguide’s insertion loss is anomalously high, around 20 dB at 2 GHz. This behavior contradicts expectations, as both lumped capacitors and transmission lines are typically lossless. Unusual results like this one may indicate a modeling mistake that either causes unphysical behavior or shows theoretically-possible but unrealistic physical effects. Alternatively, it may reveal actual physics rarely discussed in circuit textbooks, so it can be “new” to us. We will discuss this issue later.

On the other hand, the phase angle runs between -180° and 180°. This is the expected behavior consistent with real-world measurements.

Note

Loss or Gain? There’s a technicality to nitpick. The term “loss” and “gain” are often used interchangeably in the RF/microwave industry. One may say a device has a return loss of -20 dB, but strictly speaking a negative loss implies a gain. This convention is technically incorrect but usually tolerated and widely used. On the other hand, its critics insist on inverting the sign (by multiplying all values by a factor of -1) when one is speaking of “loss”. Otherwise, the proper term to speak of is “reflection coefficient”, not “return loss”.

This issue can sometimes be quite controversial. For example, IEEE Antennas and Propagation Magazine started rejecting the former convention to promote rigor as of 2009. While the author of this tutorial has no particular opinion, to satisfy the potential nitpickers while following the tradition, here we use a compromise. Plots are labeled as “Return loss” and use the positive sign convention, but also with the Y axis inverted, so that resonances appear as familiar valleys.

Plot Z-parameters (Impedances) via matplotlib

It’s straightforward to transform S-parameters to Z-parameters (impedances) using well-known formulas, so saving a redundant set of Z-parameters is unnecessary. If \(Z_0\) is the port impedance, \(S_{11}\) (also known as the reflection coefficient \(\Gamma\)) is related to the load impedance seen at the port via:

Nevertheless, it’s possible to directly calculate the impedance seen by

a port via the total voltage uf_tot and total current if_tot attributes

as well.

The following example plots the impedance seen by port 1. Like S-parameters,

all impedances are also complex numbers, so we are only looking at their

magnitude (absolute value) here:

# direct impedance calculation

z11_list = np.abs(port[0].uf_tot / port[0].if_tot)

# derive impedance from S11

z11_from_s11_list = np.abs(z0 * (1 + s11_list) / (1 - s11_list))

plt.figure()

plt.plot(freq_list / 1e9, z11_list, label='$|Z_{11}|$ (Ω)')

plt.plot(freq_list / 1e9, z11_from_s11_list, label='$|Z_{11}|$ (Ω)')

plt.grid()

plt.legend()

plt.xlabel('Frequency (GHz)')

plt.ylabel('Impedance Magnitude (Ω)')

plt.show()

We find that the impedances derived from \(S_{11}\) and from direct calculations are indistinguishable.

Important

We repeat the warning that was already given in the Purpose of Ports section. Beware that the impedance \(Z_{11}\) is not the actual impedance of the DUT, such as this parallel-plate waveguide. It’s only the total impedance seen by the port, including the contribution of both the DUT and port imperfections, which can lead to frequency-dependent artifacts. The DUT impedance can’t be read from \(Z_{11}\) without removing measurement artifacts. This can be achieved by eliminating port discontinuities or separating the contributions from the ports via de-embedding, calibration, or time gating. These are advanced topics not discussed here.

Futhermore, even after de-embedding, it’s not meaningful to associate this DUT’s impedance with a pure capacitance, since this DUT is not a lumped capacitor but a parallel-plate waveguide. Only the RLCG transmission line is be the correct model here.

Code Checkpoint 2: Eliminate Repetitions in matplotlib Code

The matplotlib examples shown above are meant to be instructional. In an actual program, we should avoid unproductive repetitions when we see them. We can write a separate plotting function to avoid repeating the same steps:

def plot_param(x_list, y_list, linelabel, xlabel, ylabel, invert_y=True):

plt.figure()

plt.plot(x_list, y_list, label=linelabel)

plt.grid()

plt.legend()

plt.xlabel(xlabel)

plt.ylabel(ylabel)

# By convention, loss values increase downward on the Y axis.

# This is consistent with the plot shapes on spectrum analyzers, and

# perhaps explains why the customary "wrong" sign convention is used.

if invert_y:

plt.gca().invert_yaxis()

plt.show()

def postproc(port):

"""

Process the data generated by a complete simulation. Only knowledge of ports

are necessary. This function is agnostic about the structure and simulator

parameters.

"""

for p in port:

p.CalcPort(simdir, freq_list, ref_impedance=z0)

s11_list = port[0].uf_ref / port[0].uf_inc

s21_list = port[1].uf_ref / port[0].uf_inc

# hack: assume symmetry and reciprocity

# This only correct for passive linear reciprocal circuit!

s22_list = s11_list

s12_list = s21_list

s11_db_list = -10 * np.log10(np.abs(s11_list) ** 2)

s21_db_list = -10 * np.log10(np.abs(s21_list) ** 2)

plot_param(freq_list / 1e9, s11_db_list, '$S_{11}$ dB', 'Frequency (GHz)', 'Return Loss (dB)')

plot_param(freq_list / 1e9, s21_db_list, '$S_{21}$ dB', 'Frequency (GHz)', 'Insertion Loss (dB)')

s11_deg_list = np.angle(s11_list, deg=True)

s21_deg_list = np.angle(s21_list, deg=True)

plot_param(freq_list / 1e9, s11_deg_list, '$S_{11}$ deg', 'Frequency (GHz)', 'S11 Phase')

plot_param(freq_list / 1e9, s21_deg_list, '$S_{21}$ deg', 'Frequency (GHz)', 'S21 Phase')

# direct impedance calculation

z11_list = np.abs(port[0].uf_tot / port[0].if_tot)

plot_param(freq_list / 1e9, z11_list, '$|Z_{11}|$ (Ω)', 'Frequency (GHz)', 'Impedance Magnitude (Ω)', invert_y=False)

Plot Time-Domain Waveforms via matplotlib

FDTD is fundamentally a time-domain field solver. In some cases it’s desirable to create custom excitations and observe transient responses directly. For example, it allows one to truncate a simulation early without waiting for convergence. It may help improving data quality by preserving the DC term, or by avoiding violations of passivity and causality in S-parameters due to numerical artifacts. Both may be problematic if the frequency-domain data is used in transient simulations.

To obtain the time-domain waveforms at a port, we can use these port

attributes: u_data.ut_tot (total voltage), u_data.ui_time[0] (time

of voltage samples), i_data.it_tot (total current), i_data.ui_time[0]

(time of current samples).

For the first try, let’s plot the voltages at port 1 and port 2:

plt.figure()

plt.plot(port[0].u_data.ui_time[0], port[0].ut_tot, label="Input Voltage")

plt.plot(port[1].u_data.ui_time[0], port[1].ut_tot, label="Output Voltage")

plt.grid()

plt.legend()

plt.xlabel('Time (s)')

plt.ylabel('Voltage (V)')

plt.show()

The excitation signal is a sinusoid at the center frequency, with its amplitude modulated by a Gaussian function. This is difficult to make sense of, since the Gaussian function decays rapidly, but the simulator continues running until the total energy has decayed below 60 dB. As a result, the waveform is a spike followed by a flatline near 0. The tail of the waveform is almost invisible, because its amplitude is many orders of magnitude smaller than the leading edge.

Let’s try again, focusing only on the first 100 samples to improve clarity:

plt.figure()

plt.plot(port[0].u_data.ui_time[0][0:100], port[0].ut_tot[0:100], label="Input Voltage")

plt.plot(port[1].u_data.ui_time[0][0:100], port[1].ut_tot[0:100], label="Output Voltage")

plt.grid()

plt.legend()

plt.xlabel('Time (s)')

plt.ylabel('Voltage (V)')

plt.show()

This is much better. The Gaussian modulation of the input signal is evident. There’s also a noticeable time delay before it reaches the output, with an attenuation of one or two orders of magnitude. Both are expected.

Time-domain usage of openEMS is most useful for custom excitation signals. For example, one use case is to study the Time-Domain Transmission and Time-Domain Reflection (TDT/TDR) characteristics of the DUT directly in the time domain, which is beyond the scope of this tutorial. Hence, this tutorial advocates relying on mature frequency-domain analysis tools based on S-parameters (which can also be used in time-domain transient simulations as well), as FDTD typically uses wideband Gaussian excitation signals that are difficult to interpret in the time domain anyway.

Hint

The raw time-domain voltages and currents at all ports are also available

in the simulation directory as port_ut_1, port_ut_2, port_it_1

and port_it_2, which can be analyzed by external programs.

Export S-parameters to Touchstone

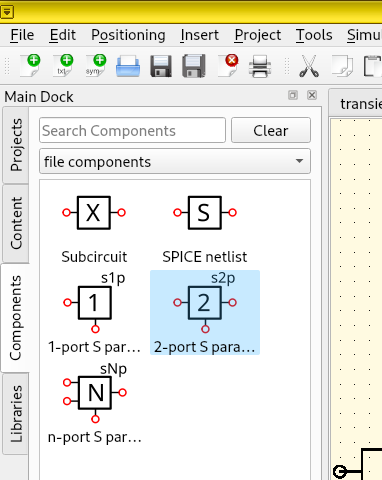

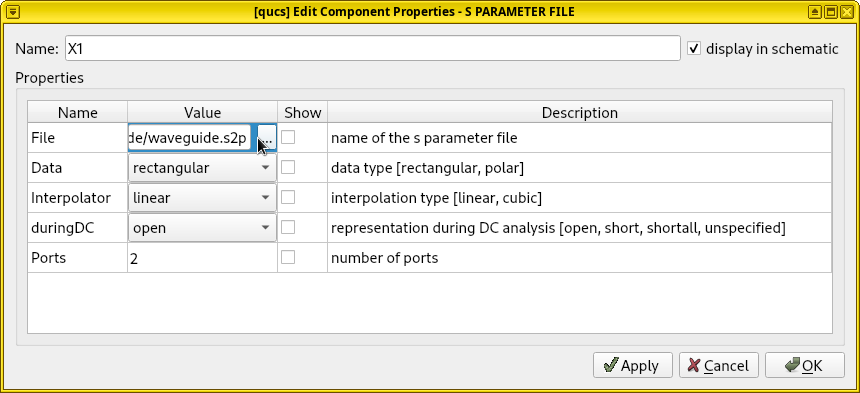

At this point, we have nearly reached the limit of the built-in post-processing capabilities of openEMS. To bring our analysis further, it’s now necessary to use third-party software. Therefore we must save our S-parameters to an external file to be used in other tools. In the RF/microwave industry, S-parameters are encoded in a de facto standard file format called a Touchstone file.

A 2-port Touchstone file has the file extension .s2p, the first line

is its metadata.

The hash (#) symbol denotes a metadata line, not a comment line.

This line is mandatory (the real comment line begins with !).

Letter S means the file contains S-parameters, keyword

RI means the complex S-parameters are in the real-imaginary format,

and the final R 50 means the port impedance for this measurement

is 50 Ω:

# Hz S RI R 50

.s2p file

In an .s2p file, each additional line defines the S-parameters at a new frequency

point, with the

order of frequency, s11_real, s11_imag, s21_real, s21_imag, s12_real,

s12_imag, s22_real, s22_imag. All variables are floating-point numbers.

Thus we can write the simulation result as a Touchstone file using the following code:

# determine a file name

s2pname = filepath.with_suffix(".s2p").name

# concat two paths

s2ppath = simdir / s2pname

# write 2-port S-parameters

with open(s2ppath, "w") as touchstone:

touchstone.write("# Hz S RI R %f\n" % z0) # Touchstone metadata, not comment!

for idx, freq in enumerate(freq_list):

s11 = s11_list[idx]

s21 = s21_list[idx]

s12 = s12_list[idx]

s22 = s22_list[idx]

entry = (freq, s11.real, s11.imag, s21.real, s21.imag, s12.real, s12.imag, s22.real, s22.imag)

touchstone.write("%f %f %f %f %f %f %f %f %f\n" % entry)

.s1p file

The .s2p file already contains the S-parameter \(S_{11}\), so

there’s no need to create a separate 1-port Touchstone file. It’s only

used for 1-port measurement data. For completeness, the Touchstone file

for 1-port measurements has the

suffix .s1p. Its format is similar: at each frequency point, one

writes a new line with parameter order of frequency, s11_real,

s11_imag:

# determine a file name

s1pname = filepath.with_suffix(".s1p").name

# concat two paths

s1ppath = simdir / s1pname

# write 1-port S-parameters

with open(s1ppath, "w") as touchstone:

touchstone.write("# Hz S RI R %f\n" % z0) # Touchstone metadata, not comment!

for idx, freq in enumerate(freq_list):

s11 = s11_list[idx]

entry = (freq, s11.real, s11.imag)

touchstone.write("%f %f %f\n" % entry)

.snp file

Finally, beware that for 3-port, 4-port, or more ports, the parameters order is different. The website Microwaves101 contains useful information here. 3

Code Checkpoint 3

As a checkpoint of our progress, the following is the complete code one obtains if the previous instructions are followed:

import sys

import math

import pathlib

import numpy as np

from matplotlib import pyplot as plt

import CSXCAD

import openEMS

from openEMS.physical_constants import C0

# calculate mesh resolution according to simulation frequency

unit = 1e-3

f_min = 100e6 # post-processing only, not used in simulation

f_max = 10e9 # determines mesh size and excitation signal bandwidth

epsilon_r = 1

v = C0 / math.sqrt(epsilon_r)

wavelength = v / f_max / unit # convert to millimeters

res = wavelength / 10

# use a smaller cell size around metal edge, not just the base mesh size

highres = res / 1.5

# calculate frequency points

points = 1000

freq_list = np.linspace(f_min, f_max, points)

# port impedance

z0 = 50

# determine the simulation output path

# find the directory of the script itself

filepath = pathlib.Path(__file__)